Method for packaging large flatbreads and fully-automatic flatbread packaging machine for achieving same

A fully automatic, large-bread technology, applied in packaging machines, packaging, transportation packaging, etc., can solve the problems of not being able to put soft food into plastic bags, not being able to meet high-efficiency requirements, and not being able to realize full automation, etc., to achieve simple structure , Reduce labor costs and production costs, and the effect of practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

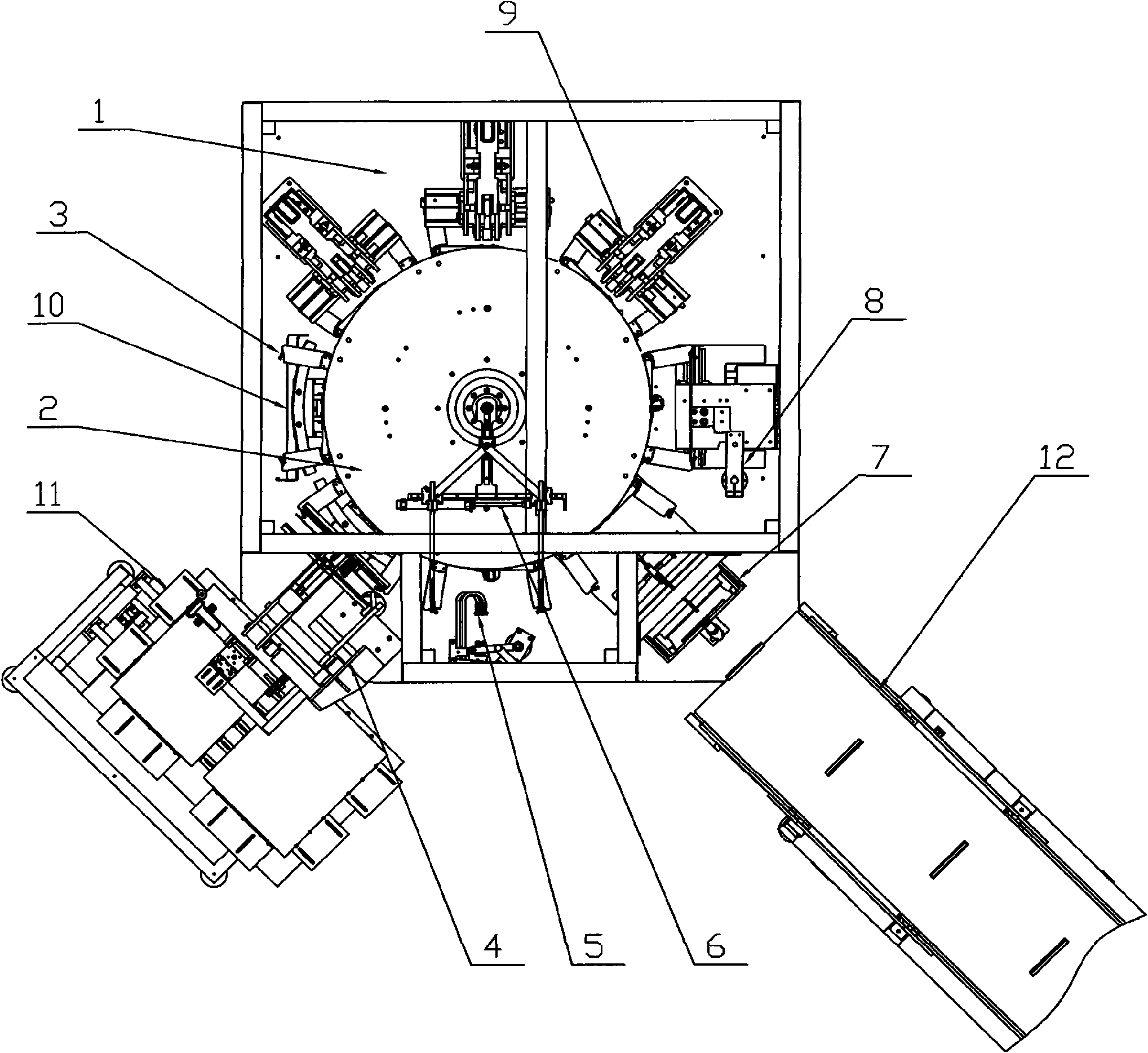

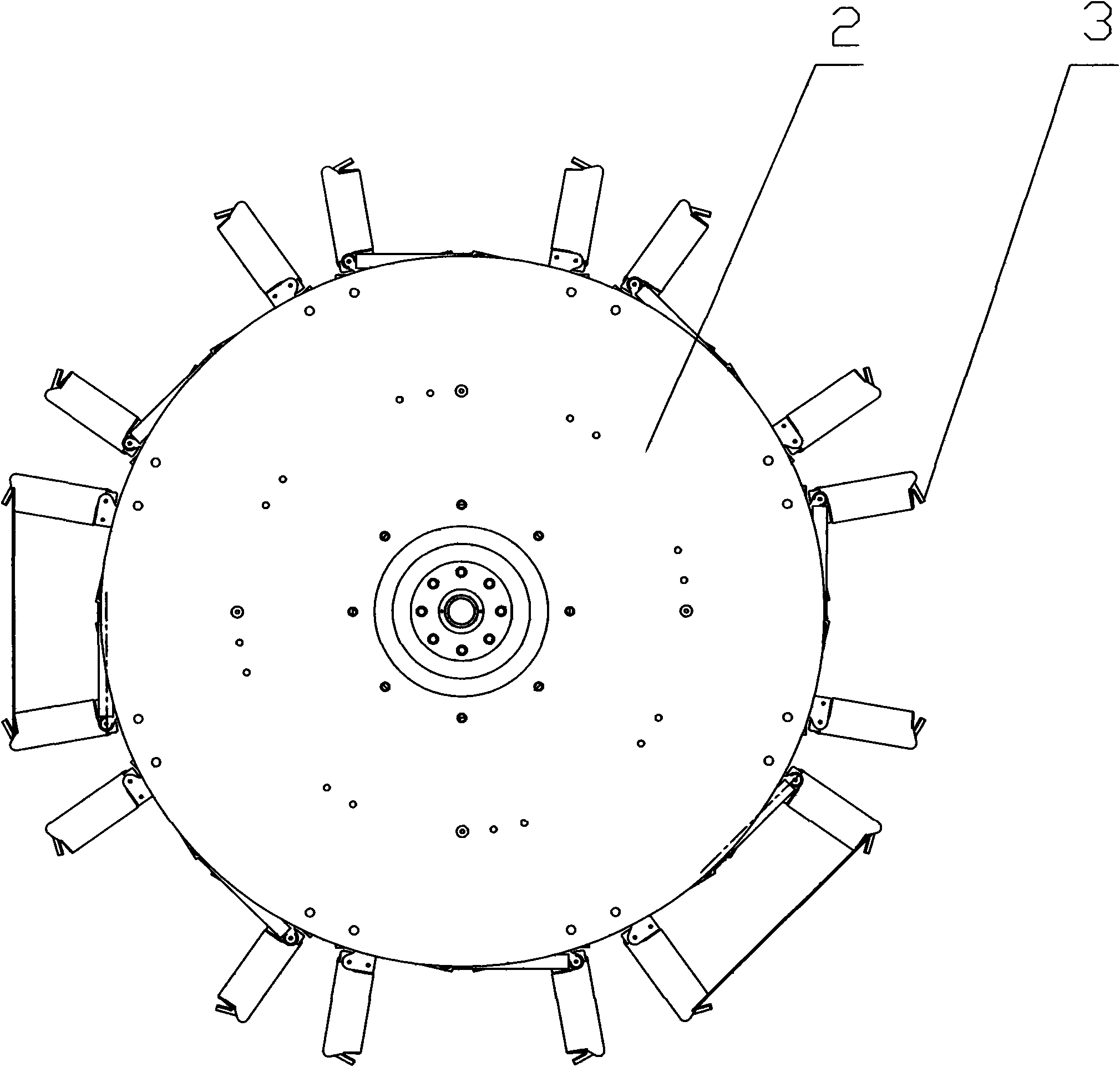

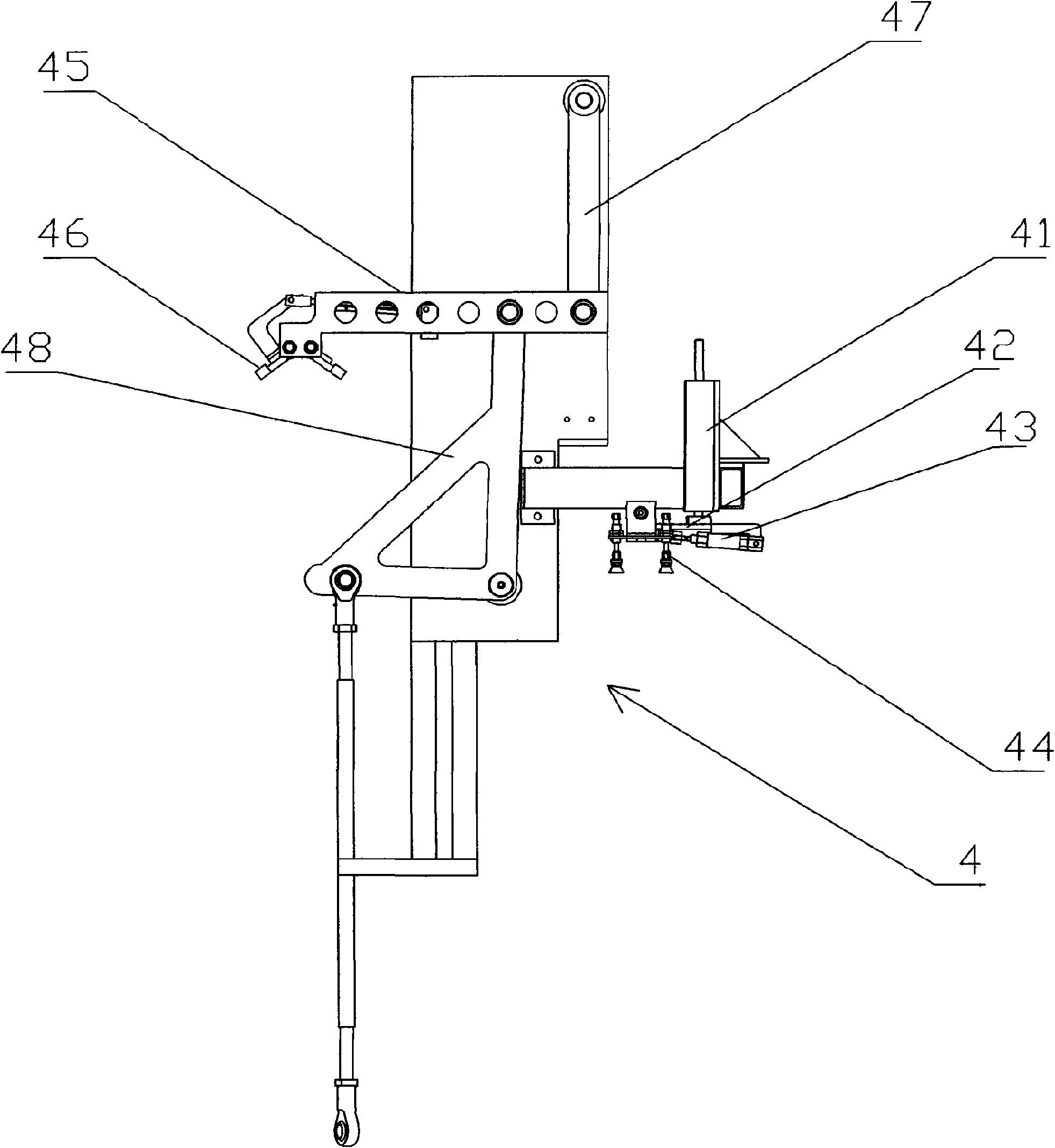

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

[0040] The method for packing flatbread is characterized in that comprising the following steps:

[0041] 1. Take out the bag: take out the packaging bag.

[0042] 2. Mouth opening: After the extracted packaging bag is opened, the mouth of the packaging bag is opened to open the mouth of the plastic bag.

[0043] 3. Keep the mouth open: After opening the mouth of the plastic bag, use a mechanism to keep the mouth of the plastic bag open.

[0044] 4. Cake loading: After keeping the mouth of the plastic bag open, use the conveyor belt and the loading mechanism to smoothly load the big cake into the plastic bag.

[0045] 5. Vacuuming: After the cake is put into a plastic bag, insert the vacuum tube into the bag, press the bag mouth with a briquetting block, the vacuum tube will discharge the air in the plastic bag to the outside, pull the vacuum tube out of the bag mouth and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com