Board width controller of hot rolling mill and control method thereof

A control device, a technology for a hot rolling mill, applied in the direction of a metal rolling stand, a metal rolling mill stand, etc., and can solve the application and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

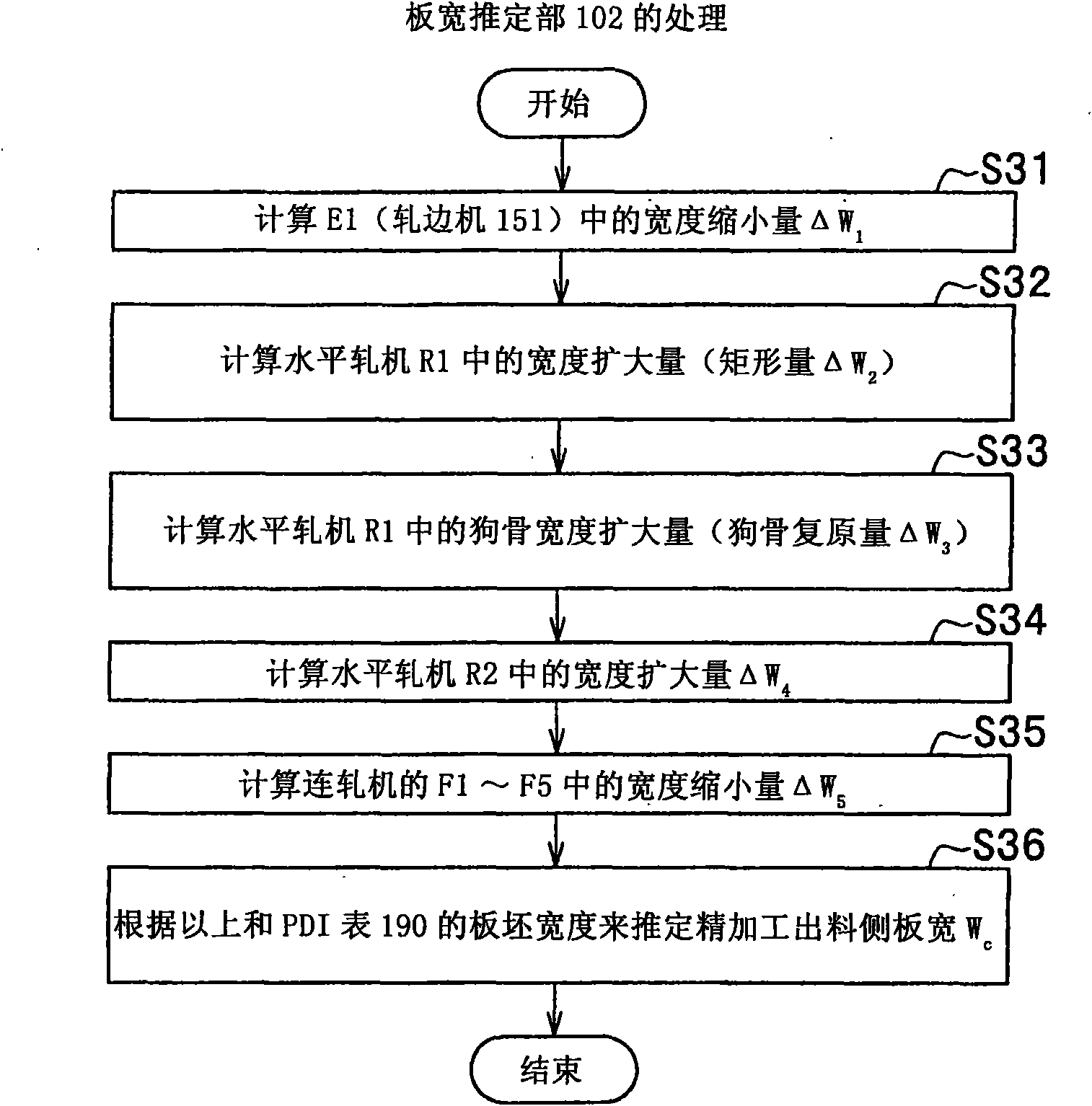

[0049] figure 1 It is a conceptual diagram which shows the structure of the control system S provided with the panel width control apparatus 100 which concerns on 1st Embodiment of this invention.

[0050] (Structure of control system S having board width control device 100)

[0051] The control system S having the strip width control device 100 of the first embodiment includes: a hot rolling mill 150, that is, hot rolling equipment; and a strip width control device 100, which receives various signals from the hot rolling mill 150 and outputs control signals to the edger 151 of the hot rolling mill 150 to be controlled, and the roll gap between the rolls 151r of the edger 151 is controlled.

[0052] (hot rolling mill 150)

[0053] First, the configuration of the hot rolling mill 150 to be controlled by the strip width control device 100 will be described.

[0054] The hot rolling mill 150 is equipment generally called a small rolling mill that performs a unified casting / rol...

no. 2 Embodiment approach

[0210] Next, the control system 2S of the second embodiment will be described.

[0211] Figure 10 It is a conceptual diagram showing the configuration of a control system 2S including an adaptive gain calculation unit 10001 in the panel width control device 100 according to the second embodiment of the present invention.

[0212] 2nd Embodiment The panel width control apparatus 100 of 1st Embodiment includes the adaptive gain calculation part 10001 which calculates adaptive gain (beta) (refer formula (12)).

[0213] Since the other configurations are the same as those of the first embodiment, the same components are given the same reference numerals, and detailed descriptions are omitted.

[0214] The adaptive gain calculation unit 10001 in the panel width control device 100 according to the second embodiment learns from the panel width deviation accumulating unit 104 (refer to Figure 4) to obtain the recent width deviation ΔWact and adaptive value ΔWadap of the steel plat...

no. 3 Embodiment approach

[0241] Figure 13 It is a figure explaining the thickness control apparatus concerning this embodiment. The panel width control device 1100 receives various signals from the controlled object 1200 and outputs the control signal to the controlled object 1200 . First, the configuration of the control object 1200 will be described.

[0242] The control object 1200 is the width control line (line) of the hot rolling mill. The slab 1205 with a width of 1000 mm to 1600 mm extracted from the slab extraction part 1210, that is, the heating furnace 1215, is drawn in the width direction by the width rolling mill 1225 of the width rolling part 1220. Rolling is performed, and the rough rolling mill 1235 of the rough rolling section 1230 performs 3-pass to 7-pass reciprocating rolling. Here, the width rolling mill 1225 and the rough rolling mill 1235 are provided adjacent to each other, and reciprocating rolling is simultaneously performed in the width rolling mill 1225 and the rough rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com