Method for efficiently selecting lead with high-enriched fineness

A high-density, high-efficiency technology, applied in flotation, solid separation and other directions, can solve the problems of unimproved mineral monomer dissociation degree, low index, and too much water for beneficiation, so as to achieve high-efficiency separation and cleaning of lead. The effect of production, saving electricity consumption and improving lead beneficiation index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 (test)

[0016] Through sampling assay, the character of raw ore in the present embodiment is: lead-zinc sulfide ore raw ore multi-genus content (wt%): Pb3.5, Zn6.5, S27, Ag175g / t. Ore oxidation rate: Pb4.25%, Zn5.14%.

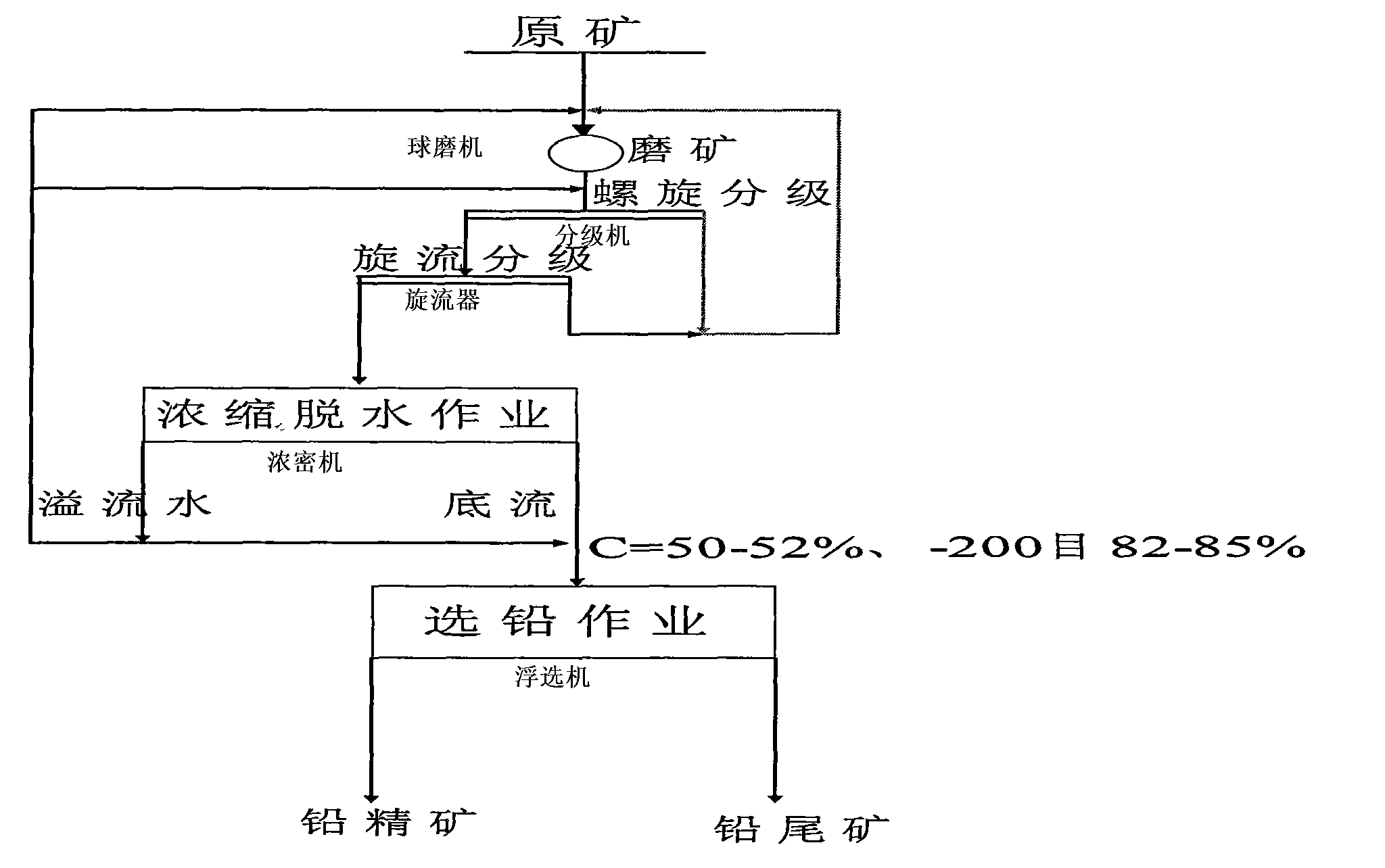

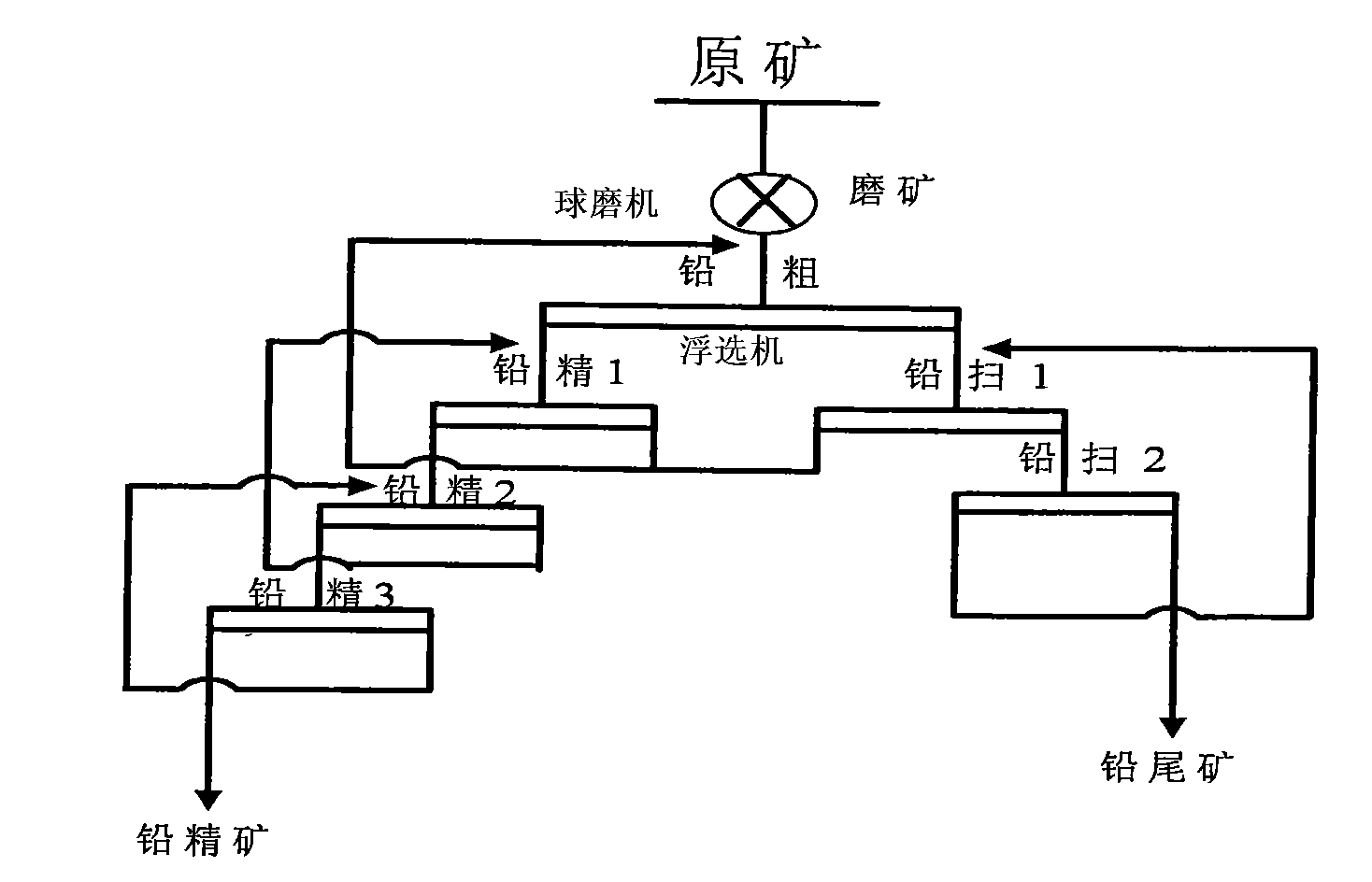

[0017] see figure 2 , in the case of the first-stage mill, the raw ore is sent to the spiral classifier after being ball milled by the ball mill for classification, and the pulp overflowed from the spiral classifier is sent to the cyclone for classification, and the fineness qualified pulp overflowed from the cyclone is sent to the The thickener is concentrated and reaches the following indicators before being sent to the floating washing machine for lead selection:

[0018] The pulp Ph 11.5, the pulp concentration is 35%, and the grinding fineness is 0.074mm (-200 mesh) is 70%-90%.

[0019] The present embodiment adopts conventional prior art to carry out the lead selection operation (the following examples are the same), and the med...

Embodiment 2

[0026] Embodiment 2 (test)

[0027] The ore properties and mineral composition of the present embodiment are the same as in Example 1, and the relevant process steps are also the same as in Example 1.

[0028] The pulp with qualified fineness overflowed from the cyclone is sent to the thickener for thickening and reaches the following indicators before being sent to the float washing machine for lead selection:

[0029] The pulp Ph 11.5; the pulp concentration is 35%-50%, and the grinding fineness -200 mesh (-0.074mm) is 75%.

[0030] The chemical system when selecting lead is: aniline 30g / t, sulfur nitrogen 15g / t, zinc sulfate 1500g / t, sodium sulfite 600g / t, terpineol oil 30g / t.

[0031] The laboratory closed-circuit results of this embodiment are shown in Table 2.

[0032] Table 2: Comparative results of test index of embodiment 2

[0033]

[0034] Another key link of the present invention is to increase the pulp concentration from 20%-25% to 50%-55% through the thic...

Embodiment 3

[0036] Embodiment 3 (test)

[0037] The ore properties and mineral composition of this embodiment are the same as those in Example 1, and the relevant process steps are also the same as in Example 1.

[0038] The pulp with qualified fineness overflowed from the cyclone is sent to the thickener for thickening and reaches the following indicators before being sent to the float washing machine for lead selection:

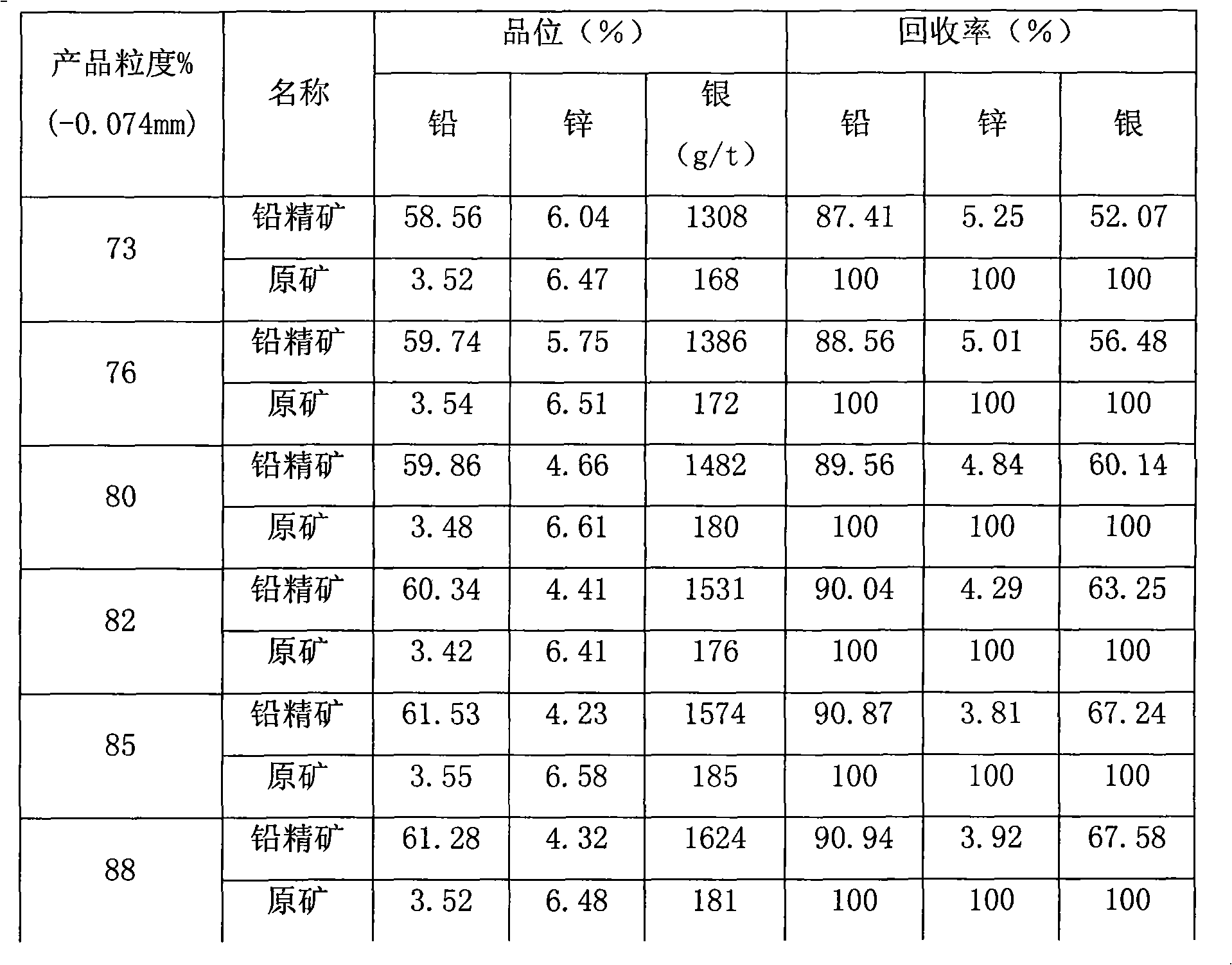

[0039] The pulp Ph 11.5; the pulp concentration is 50%, and the grinding fineness -200 mesh (-0.074mm) is 85%.

[0040] The chemical system when selecting lead is: aniline 30g / t, sulfur nitrogen 15g / t, zinc sulfate 1500g / t, sodium sulfite 600g / t, terpineol oil 30g / t.

[0041] The laboratory closed-circuit results of this embodiment are shown in Table 3.

[0042] Table 3: Comparative results of test index in embodiment 3

[0043]

[0044] Compared with the traditional one-stage grinding and spiral classifier process, this embodiment reduces the grinding fineness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com