Differential confocal aiming triggering type microscopic measuring method and device based on resonance girder scanning

A differential confocal and microscopic measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of small range, low speed, inability to measure steps and large inclined samples, etc., to improve linearity, reduce Influence of Measurement Results, Effect of Improving Tomography Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

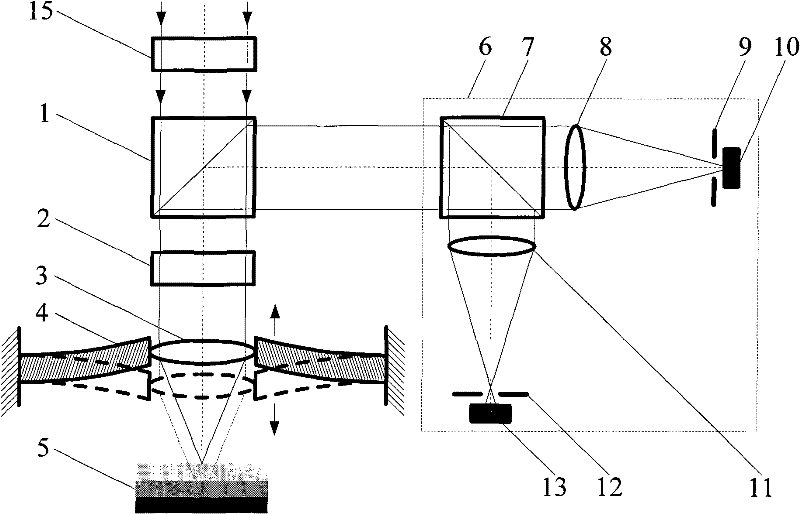

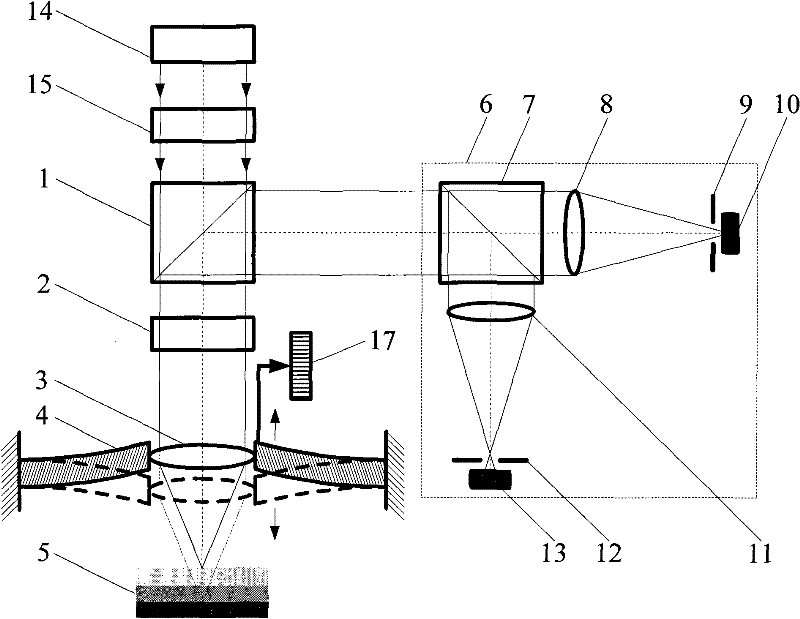

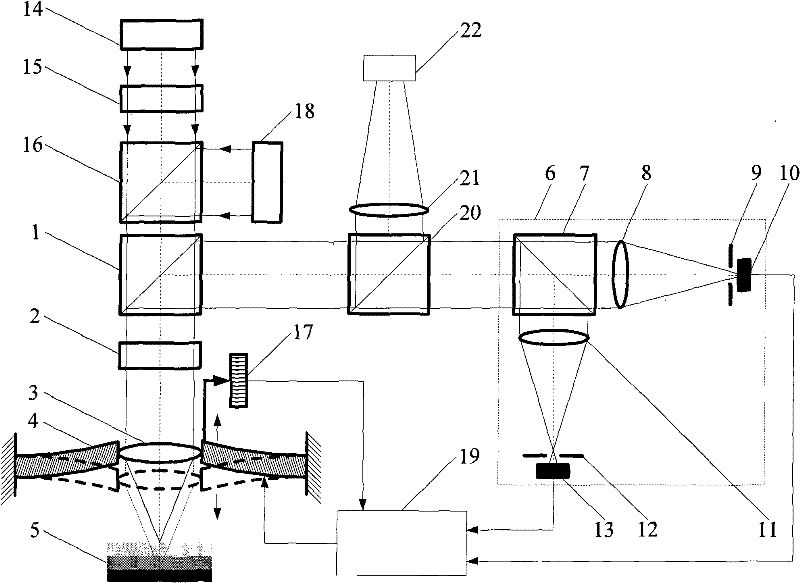

[0048] Such as image 3 As shown, a differential confocal aiming trigger microscopic measurement method based on resonant beam scanning, the measurement steps are:

[0049] First, turn on the light source 14, emit parallel light, pass through the spectroscopic system composed of the polarizing beam splitter 1 and the 1 / 4 wave plate 2, converge on the surface of the tested sample 5 through the lens 3, and the light is reflected by the surface of the tested sample 5 Finally, it is reflected by the 1 / 4 wave plate 2 and the polarizing beam splitter 1 into the beam splitter 7 in the differential confocal collimation system 6; The object 10, the reflected light passes through the lens 11 and the pinhole 12 to the detector 13; the vibration of the resonant beam drives the objective lens 3 to perform reciprocating scanning in the direction of the optical axis. The response curve of the differential confocal aiming system 6 is as follows Figure 4 shown. By detecting the zero point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com