Zero energy consumption temperature reducing humidifier for bus shelter

A humidification device and zero energy consumption technology, which is applied in the field of cooling and humidification devices, can solve the problems of no ventilation and cooling measures in the waiting hall, which affects the health of waiting passengers, and achieves an effect that is conducive to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

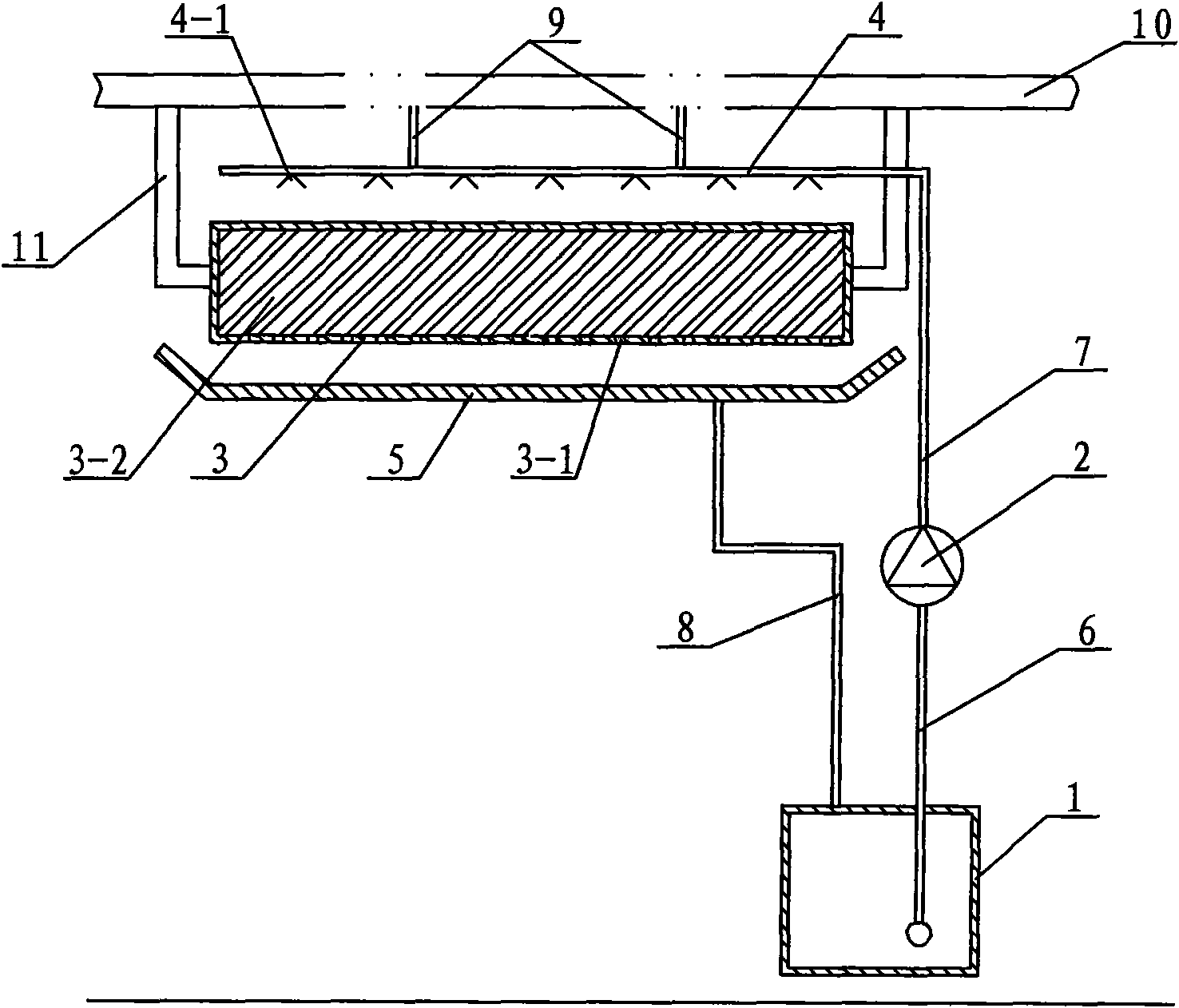

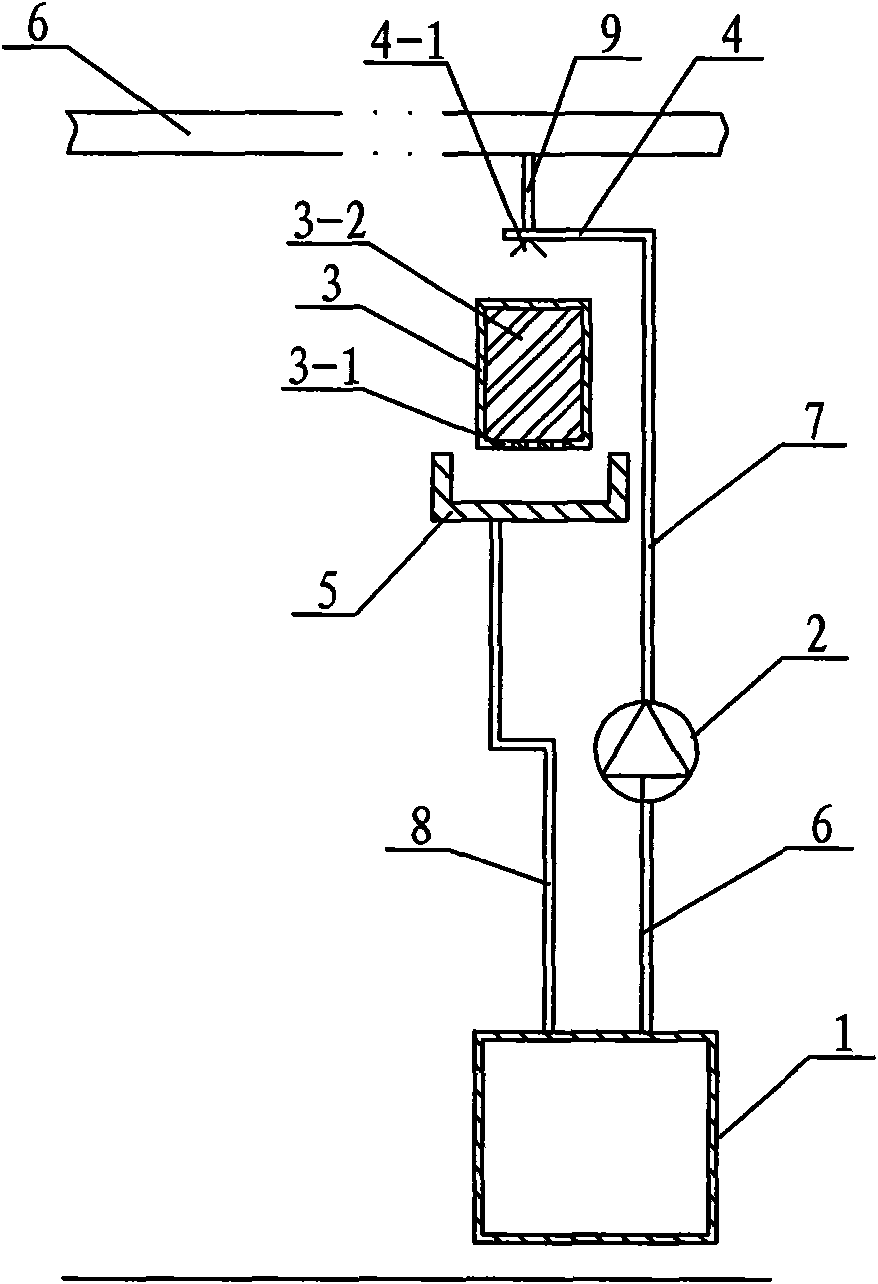

[0007] Specific implementation mode one: combine figure 1 and figure 2 This embodiment is described. This embodiment is composed of a water tank 1, a water pump 2, a stuffing box 3, a water distributor 4, a water collecting pan 5, a first pipeline 6, a second pipeline 7 and a third pipeline 8. The water tank 1 The first pipeline 6 is connected to the water inlet of the water pump 2, and the water outlet of the water pump 2 is connected to the input end of the water distributor 4 through the second pipeline 7. The stuffing box 3 is located below the water distributor 4, and the water collecting pan 5 Set below the stuffing box 3, the water outlet on the water collecting tray 5 is connected to the water tank 1 through the third pipeline 8, the stuffing box 3 is filled with hygroscopic material 3-2, and the bottom of the stuffing box 3 is provided with some water leakage holes 3 -1. Hygroscopic materials have the function of absorbing and releasing moisture, and are particular...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 The present embodiment will be described. The hygroscopic material in the stuffing box 3 of the present embodiment is paper scraps. Sawdust or paper chips can absorb or release moisture according to changes in the humidity of the surrounding environment. Other methods are the same as in the first embodiment.

[0009] Working process of the present invention: refer to figure 1 and figure 2 , the present invention runs in summer, and the roof of the bus shelter 10 is equipped with solar photovoltaic panels, and the solar photovoltaic panels are used to generate electricity to drive the water pump 2 to run, and the water pump 2 pumps the water in the water tank 1 to the water distributor 4, and then Water is sprayed onto the hygroscopic material in the stuffing box 3 through the spout 4-1 on it, and the air absorbs the heat in the air through the evaporation cooling of water in the hygroscopic material, reduces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com