Over-temperature protection device for waste gas treatment

A technology for over-temperature protection and exhaust gas treatment, which is applied in the direction of combustion methods, lighting and heating equipment, combustion types, etc., and can solve problems such as system over-temperature, shutdown, and machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

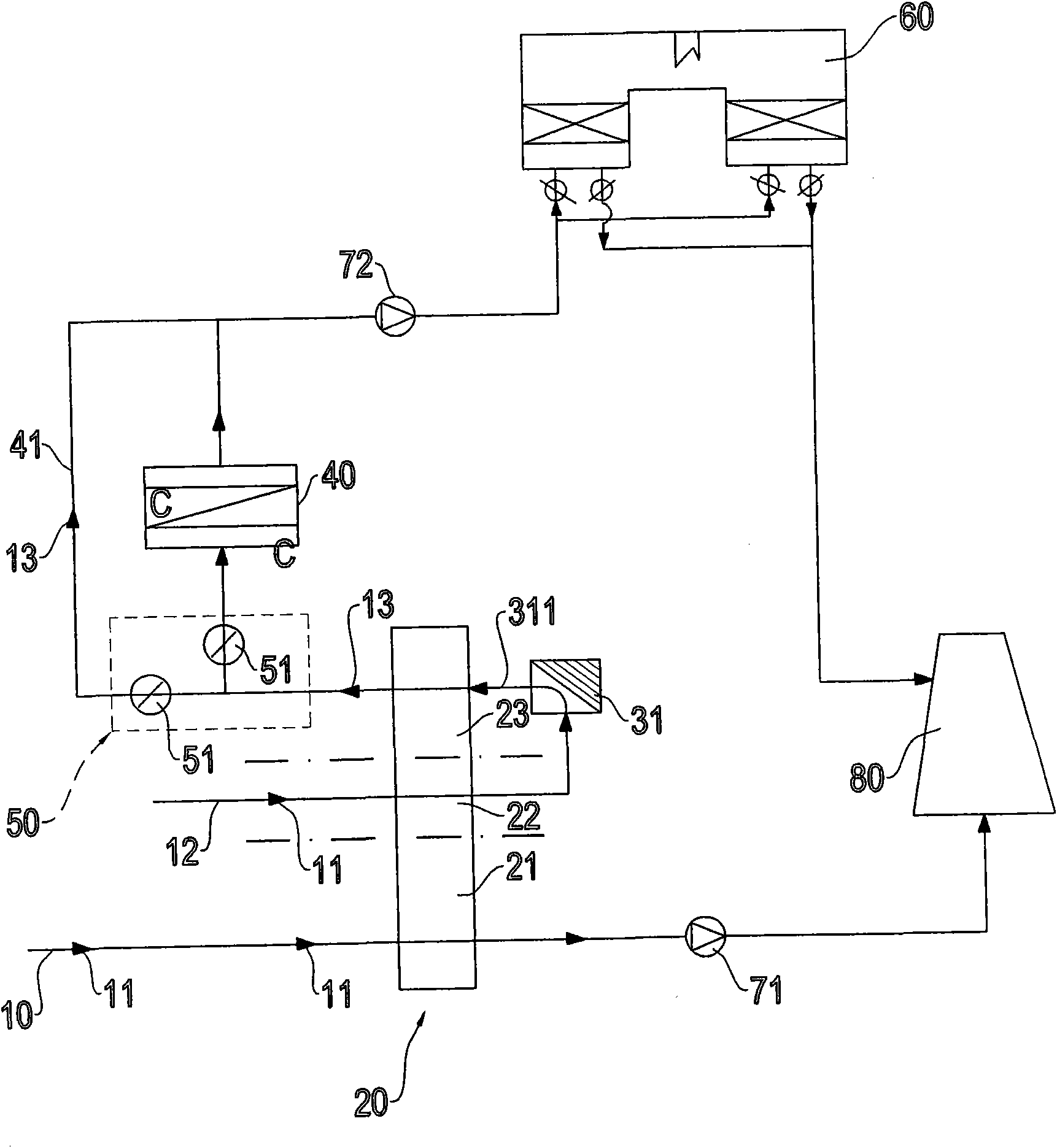

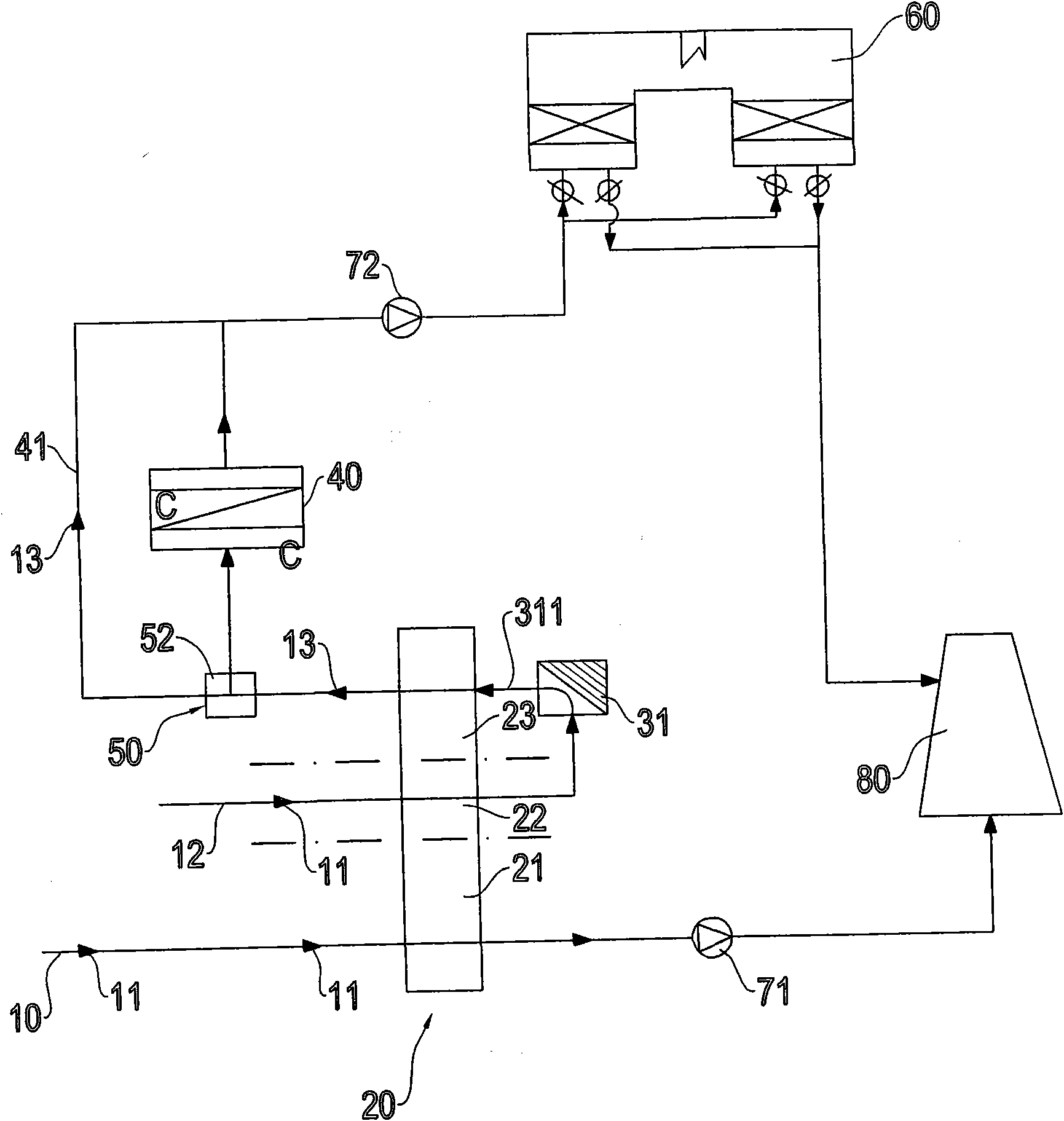

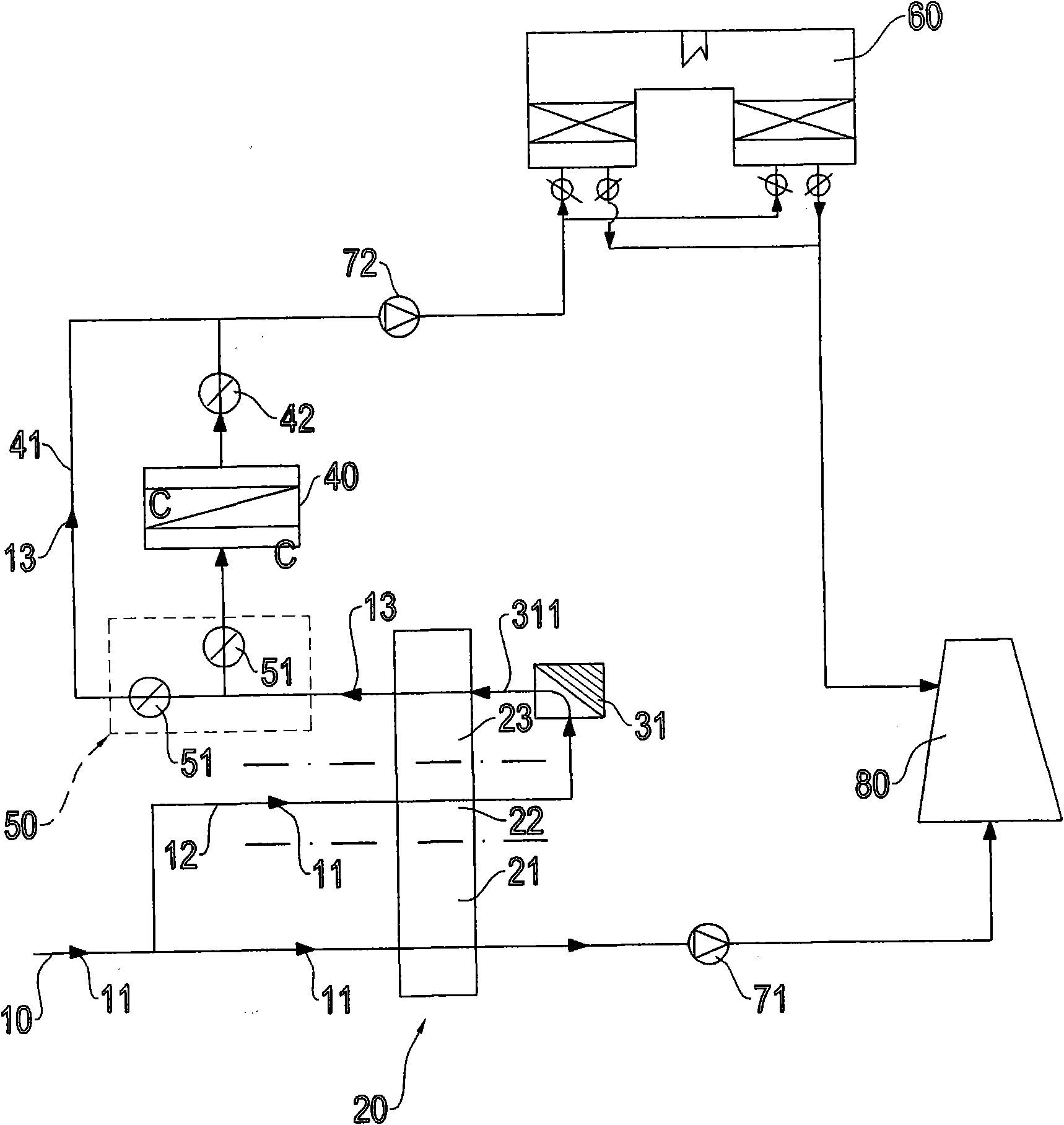

[0028] Please refer to figure 1 As shown, it is a schematic structural diagram of the exhaust gas treatment over-temperature protection device of the present invention. The exhaust gas treatment over-temperature protection device includes an exhaust gas intake pipeline 10, a concentration runner 20, a second intake pipeline 12, a heat source device 31, A heat exchanger 40 , a direction regulating valve group 50 , an exhaust bypass duct (By Pass) 41 , a combustion furnace 60 , a first exhaust fan 71 , a second exhaust fan 72 and a chimney 80 .

[0029] Wherein, the waste gas 11 of the propylene glycol monomethyl ether ester (PGMEA: Propylene Glycol MonomethylEther Acetate), propylene glycol monomethyl ether (PGME: Propylene Glycol MonomethylEther)... etc. enters from the waste gas inlet line 10, and the concentration runner 20 is divided into an adsorption zone 21, a cooling zone 22 and a desorption zone 23, and the adsorption zone 21, the cooling zone 22 and the desorption zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com