Cylindrical impulse-type hydraulic drive special for fan of cooling tower

An impulse, tower fan technology, applied in the direction of machine/engine, mechanical equipment, non-variable-capacity pump, etc., can solve the problems of low energy conversion efficiency, large plane size, and rotational speed mismatch of hydraulic turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

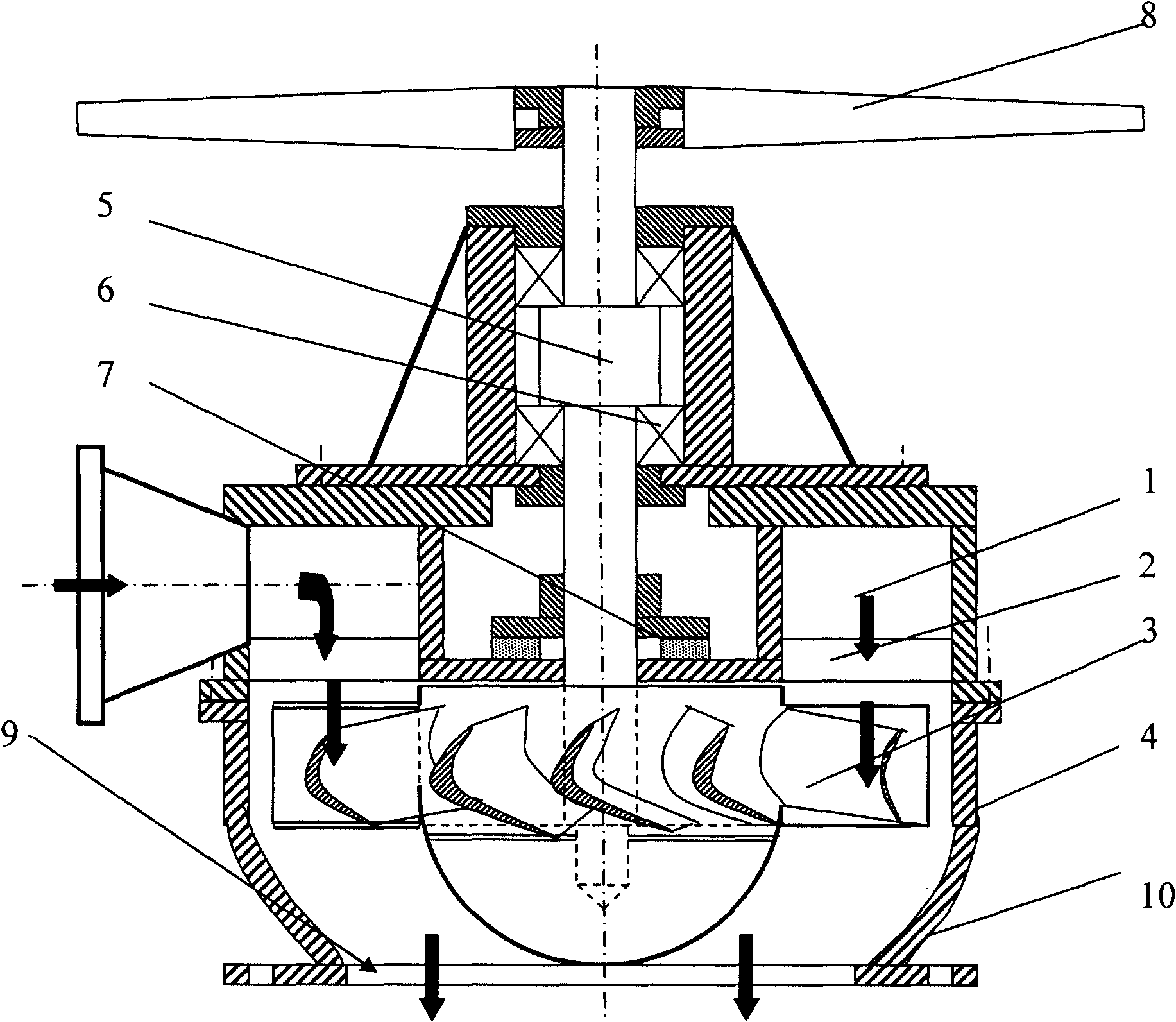

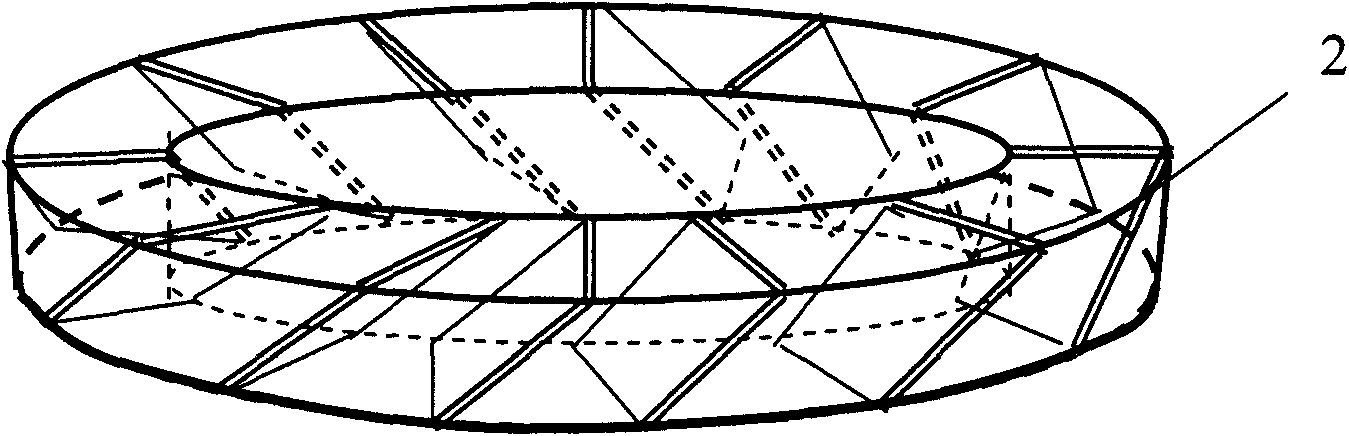

[0012] Depend on figure 1 , 2 As shown, the present invention includes a water diversion chamber, a water diversion chamber, a turbine and a main shaft. An annular axial guide vane is installed in the diversion chamber 2 below the diversion chamber 1. The impulsive turbine 3 is installed in the turbine chamber 4 in the way of non-impact inlet. The water flows through the turbine and is discharged from the water outlet 9 of the draft pipe 10. The water diversion chamber, water guide chamber and turbine chamber are all the same. Diameter, arranged in a cylindrical shape from top to bottom, the upper part of the worm gear chamber passes through the water diversion chamber and is sealed 7. The combined bearing 6 is installed on the turbine main shaft 5.

[0013] In order to ensure the effective use of water flow energy, the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com