Electrostatic spinning method and device for controlling fiber adhesion

An electrospinning and fiber technology, applied in the field of electrospinning methods and devices for controlling fiber adhesion, can solve the problems of increased spinning cost, adhesion, complicated implementation, etc., and achieves the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

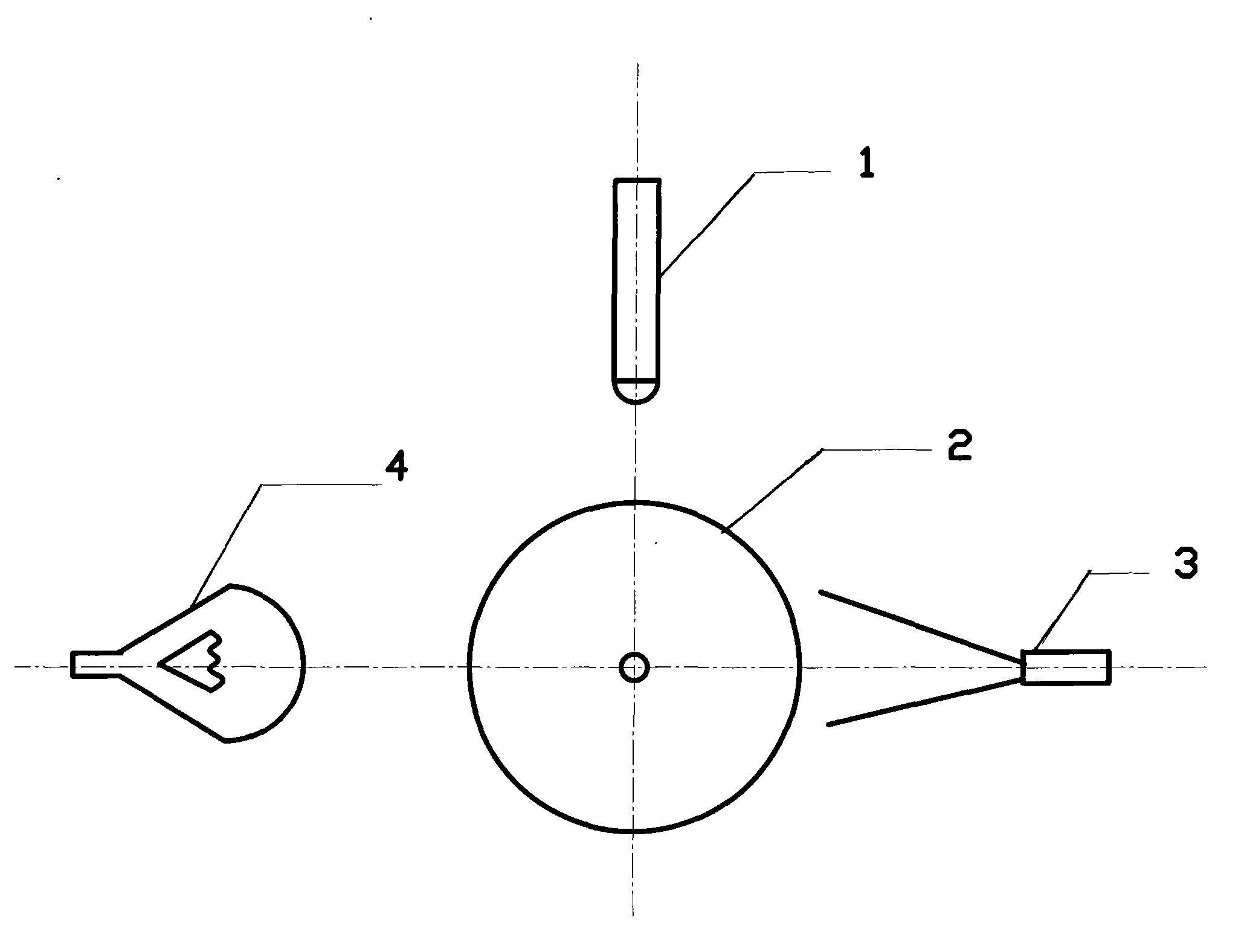

Embodiment 1

[0019] Embodiment 1: On the electrospinning device comprising spinneret and drum collector, there is an oil agent sprayer at the initial position where the drum collector collects fibers. There is an infrared drier at the terminal position, the distance between the spinneret and the collector is 14cm, the polymer solution is polyacrylonitrile (PAN) / N, N-2 dimethylformamide (DMF), and the PAN concentration is 15%. The spinneret sprays and spins, and the drum collector collects. The spinning voltage is 35kv, the surface line speed of the collector is 8m / s, the oil in the oil sprayer is dimethyl silicone oil, and the solvent is alcohol. The concentration of the oil solution is 0.5% dilute solution, the spray flow rate of the sprayer oil solution is 20ml / min, the initial fiber oiling agent is collected, and then passes through the infrared dryer, the power of the dryer is 250W, and the distance from the collector is 12cm, and the dried fiber leaves the collector device, the fiber ...

Embodiment 2

[0020] Embodiment 2: device and method step are the same as embodiment 1, wherein changing polymer solution is polyacrylonitrile (PAN) / N, N-2 dimethylformamide (DMF), PAN concentration is 13%, collector surface line The speed is 8m / s, the spinning voltage is 35kv, the distance between the spinneret and the collector is 16cm, the power of the infrared dryer is 250W, and the distance from the collector is 12cm. The oil is simethicone, the solvent is alcohol, and the concentration of the oil solution is 1%. The liquid flow rate in the nebulizer was 20ml / min. The distance between the oil sprayer and the collecting drum is 8 cm. Spray-oiled fibers are observed through a microscope, every 1000 μm 2 There are 3-8 adhesion points in the field of view, every 1000μm after pre-oxidation 2 The visual field contains 4-10 adhesion points.

Embodiment 3

[0021] Embodiment 3: device and method step are the same as embodiment 1, wherein change polymer solution is polyacrylonitrile (PAN) / N, N-2 dimethylformamide (DMF), PAN concentration is 15%, collector surface line The speed is 8m / s, the spinning voltage is 35kv, the distance between the spinneret and the collector is 14cm, the power of the infrared dryer is 250W, and the distance from the collector is 12cm. The oil is simethicone, the solvent is alcohol, and the concentration of the oil solution is 0.3%. The liquid flow rate in the nebulizer was 20ml / min. The distance between the oil sprayer and the collecting drum is 8 cm. Spray-oiled fibers are observed through a microscope, every 1000 μm 2 There are 5-10 adhesion points in the field of view, every 1000μm after pre-oxidation 2 The visual field contains 6-15 adhesion points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com