High temperature resistant molten salt corrosion ceramet anode material and preparation method thereof

A metal-ceramic anode and molten salt corrosion technology, applied in the field of material science, can solve problems such as the need to improve the corrosion resistance of grain boundaries, and achieve the effects of eliminating interconnected pores at grain boundaries, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

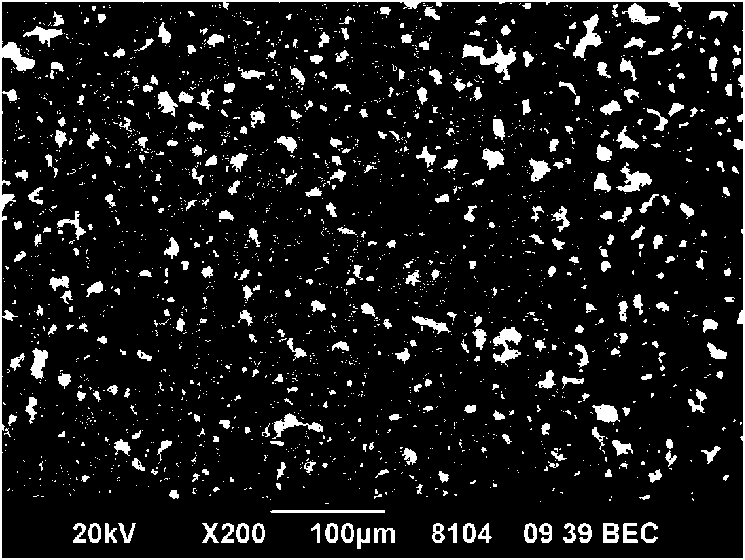

[0027] Example 1: 0.50Yb 2 o 3 -10Cu / (10NiO-NiFe 2 o 4 ) cermet inert anode

[0028] 0.50Yb 2 o 3 -10Cu / (10NiO-NiFe 2 o 4 ) The raw material formula of cermet inert anode is shown in Table 1.

[0029] Table 10.50Yb 2 o 3 -10Cu / (10NiO-NiFe 2 o 4 ) Raw material formula example of cermet inert anode

[0030] raw material

Mass percentage (%)

Yb 2 o 3

0.50

NiO

8.95

NiFe 2 o 4

80.55

Cu

10.00

[0031] Weigh Fe respectively by mass fraction of 61.32% and 38.68% 2 o 3 Powder and NiO powder, the particle size is 1.4μm and 4.1μm, respectively, mixed by ball milling for 2.5h and dried at 100°C, put into corundum crucible, place in a resistance furnace, and calcined at 1200°C for 6h under air atmosphere to obtain NiFe 2 o 4 Spinel ceramic powder, then add NiFe 2 o 4 Spinel, NiO oxide, Cu metal and Yb 2 o 3 Mix the powders together, the particle sizes are 8.1 μm, 4.1 μm, 10 μm and 3.1 μm respec...

Embodiment 2

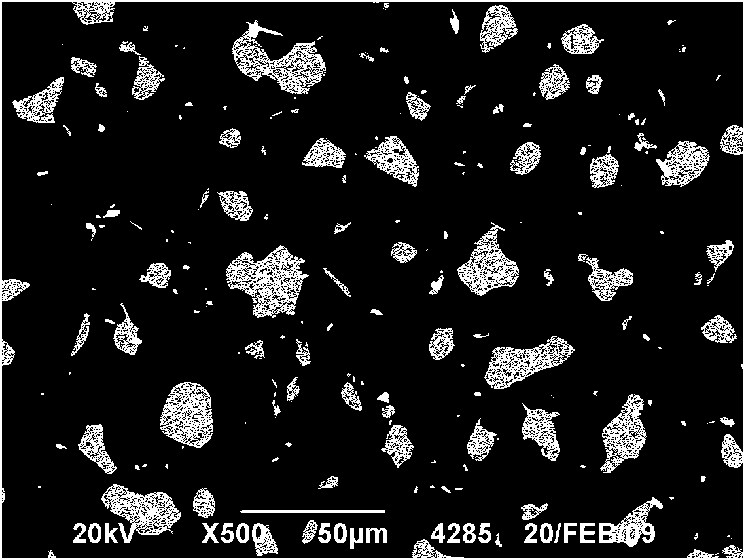

[0035] Example 2: 0.50Yb 2 o 3 -3Ni-12Cu / (10NiO-NiFe 2 o 4 ) cermet inert anode

[0036] 0.50Yb 2 o 3 -3Ni-12Cu / (10NiO-NiFe 2 o 4 ) The raw material formulation of the cermet inert anode is shown in Table 2.

[0037] Table 20.50Yb 2 o 3 -3Ni-12Cu / (10NiO-NiFe 2 o 4 ) Raw material formula example of cermet inert anode

[0038] raw material

[0039] According to the mass fraction of 61.32% and 38.68%, respectively take the analytically pure Fe 2 o 3 Powder and analytically pure NiO powder, the particle size is 1.4μm and 4.1μm respectively, mixed by ball milling for 2.5h and dried at 100°C, put into a corundum crucible, put in a resistance furnace, and calcined at 1200°C for 6h in an air atmosphere to obtain NiFe 2 o 4 Spinel ceramic powder, then add NiFe 2 o 4 Spinel, NiO oxide, Cu-Ni metal and Yb 2 o 3 The powders are mixed together, the particle sizes are 8.1 μm, 4.1 μm, 12 μm and 3.1 μm respectively, with denatured alcohol as the dispersant and 1wt...

Embodiment 3

[0040] Example 3: 0.25Yb 2 o 3 -3Ni-12Cu / (10NiO-NiFe 2 o 4 ) cermet inert anode

[0041] 0.25Yb 2 o 3 -3Ni-12Cu / (10NiO-NiFe 2 o 4 ) The raw material formulation of the cermet inert anode is shown in Table 3.

[0042] Table 30.25Yb 2 o 3 -3Ni-12Cu / (10NiO-NiFe 2 o 4 ) Raw material formula example of cermet inert anode

[0043] raw material

[0044] According to the mass fraction of 61.32% and 38.68%, respectively take the analytically pure Fe 2 o 3 Powder and analytically pure NiO powder, the particle size is 1.4μm and 4.1μm respectively, mixed by ball milling for 2.5h and dried at 100°C, put into a corundum crucible, put in a resistance furnace, and calcined at 1200°C for 6h in an air atmosphere to obtain NiFe 2 o 4 Spinel ceramic powder, then add NiFe 2 o 4 Spinel, NiO oxide, Cu-Ni metal and Yb 2 o 3 The powders are mixed together, the particle sizes are 8.1 μm, 4.1 μm, 12 μm and 3.1 μm respectively, with denatured alcohol as the dispersant and 1wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com