Amphiprotic high-molecule chelated flocculating agent and preparation method thereof

A technology of amphoteric polymers and flocculants, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of limited number of chelating groups, loose flocs, and reduced flocculation and settlement performance, so as to promote the formation and growth of flocs , The floc is dense and coarse, and the effect of sediment dehydration is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

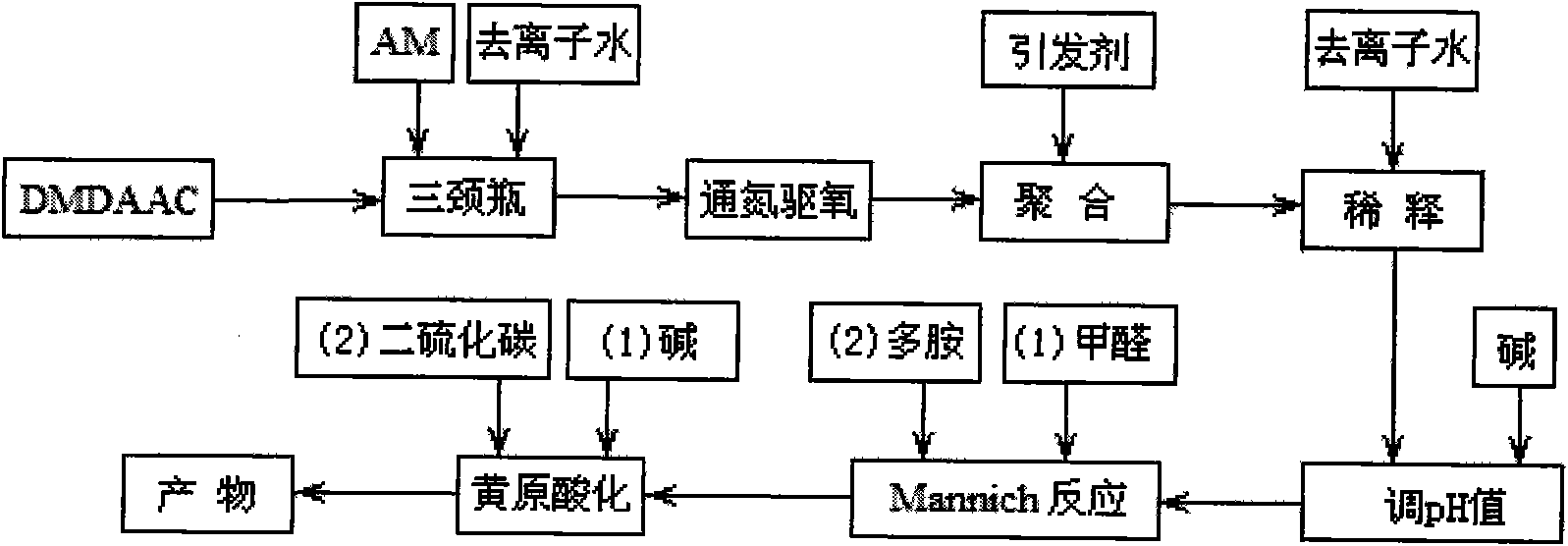

Method used

Image

Examples

Embodiment 1

[0057] (1) According to the molar ratio of dimethyl diallyl ammonium chloride (DMDAAC) and acrylamide (AM) as 0.05:1, 14.22 g of refined acrylamide (AM) and 1.62 g of dimethyl diallyl were respectively Add ammonium chloride (DMDAAC) into a 500mL three-neck flask with a dropping funnel and a mechanical stirrer, and add 143mL of deionized water to dissolve to make a solution with a mass percentage concentration of 10%;

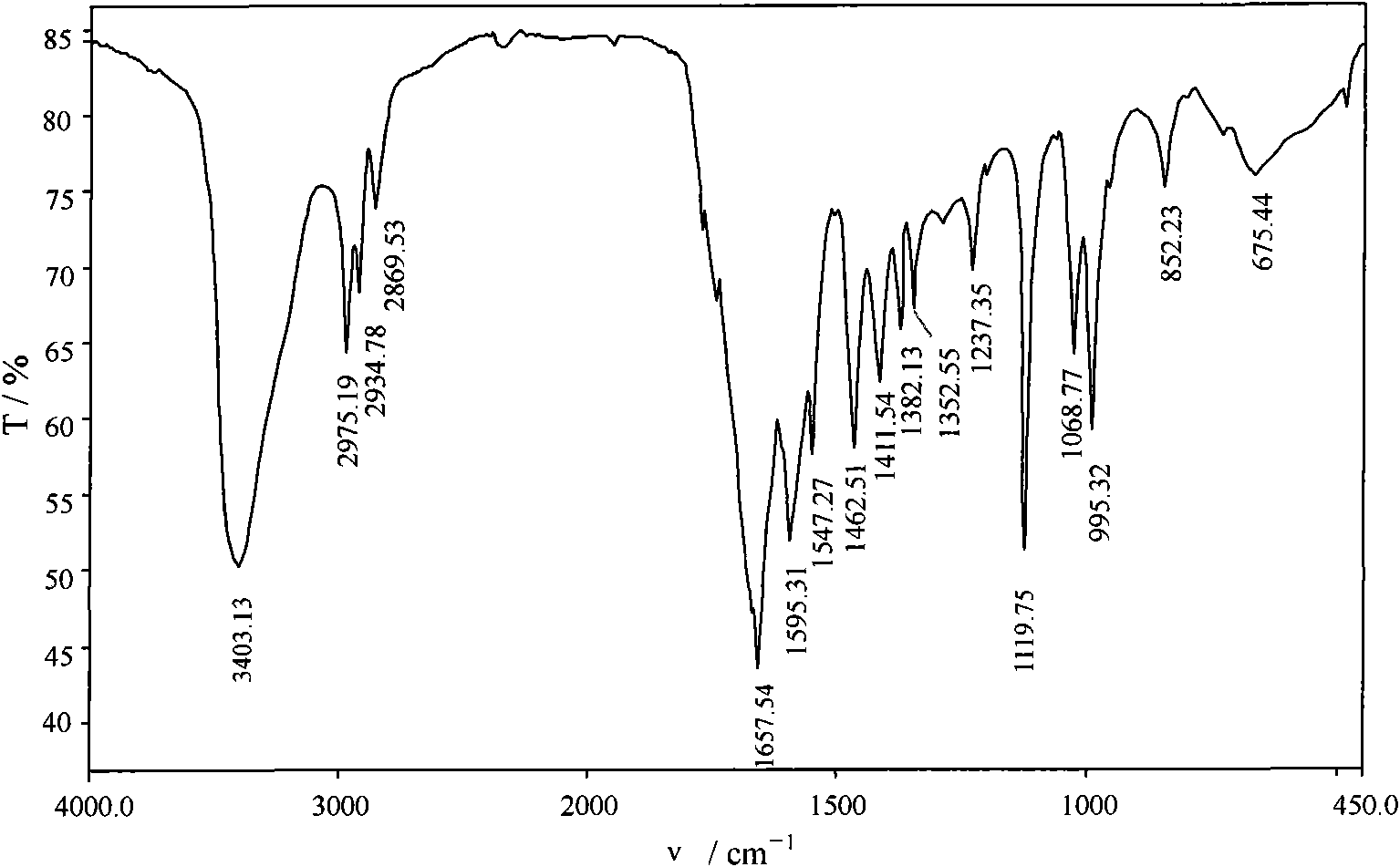

[0058] (2) pass N in the solution of step (1) 2 Expel oxygen for 30min, raise the temperature to 50°C, add 2 mL of ammonium persulfate solution with a mass percentage concentration of 5% dropwise within 60min, after the reaction for 3h, add dropwise the remaining 0.6mL of ammonium persulfate solution, raise the temperature to 55°C, and react for 1h, A colorless or light yellow viscous liquid was obtained; take a small amount of the viscous liquid and dilute it with methanol, then drop the diluted viscous liquid into acetone for precipitation, repeat the precipit...

Embodiment 2

[0063] (1) prepare the copolymer P (DMDAAC-AM) of DMDAAC and AM according to the proportioning and operation steps of embodiment 1, measure its intrinsic viscosity [η] and be 483mL / g, and cationicity is 4.63mol%;

[0064] (2) in step (1) colorless or light yellow viscous liquid is added 158mL deionized water to be made into a solution with a mass percentage concentration of 5%, and NaOH solution is added to adjust pH to 10.3;

[0065] (3) In the solution of step (2), the molar ratio of AM, formaldehyde and triethylenetetramine is 1:0.9:1.0, drop 13.3 mL of formaldehyde solution with a mass percentage concentration of 37.0%, and react at 45°C for 30min , and then 31.5 mL of triethylenetetramine was added to continue the reaction for 3h;

[0066] (4) the solution of step (3) is lowered to room temperature, the molar ratio of N atom, alkali and carbon disulfide in the triethylenetetramine molecule is 1: 1.2: 0.9, adding 85.3g mass percent concentration is 45% NaOH solution, and t...

Embodiment 3

[0068] (1) prepare the copolymer P (DMDAAC-AM) of DMDAAC and AM according to the proportioning and operation steps of embodiment 1, measure its intrinsic viscosity [η] and be 469mL / g, and cationicity is 4.71mol%;

[0069] (2) in step (1) colorless or light yellow viscous liquid is added 158mL deionized water to be made into a solution with a mass percentage concentration of 5%, and KOH solution is added to adjust pH to 10.5;

[0070] (3) In the solution of step (2), the molar ratio of AM, formaldehyde and triethylenetetramine is 1:1.0:1.1, drop 14.8 mL of formaldehyde solution with a mass percentage concentration of 37.0%, and react at 45°C for 30min , and then added 34.6 mL of triethylenetetramine to continue the reaction for 3h;

[0071] (4) the solution of step (3) is lowered to room temperature, and the molar ratio of N atom, alkali and carbon disulfide in triethylenetetramine molecule is 1: 1.3: 1.0, adding 143g mass percent concentration is 45% KOH solution, and then dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com