Welding fixture and welding method

A technology of welding device and welding method, which is applied in the direction of welding/welding/cutting items, welding equipment, manufacturing tools, etc., and can solve problems such as poor welding of welding points and inability to fully melt the self-contained solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

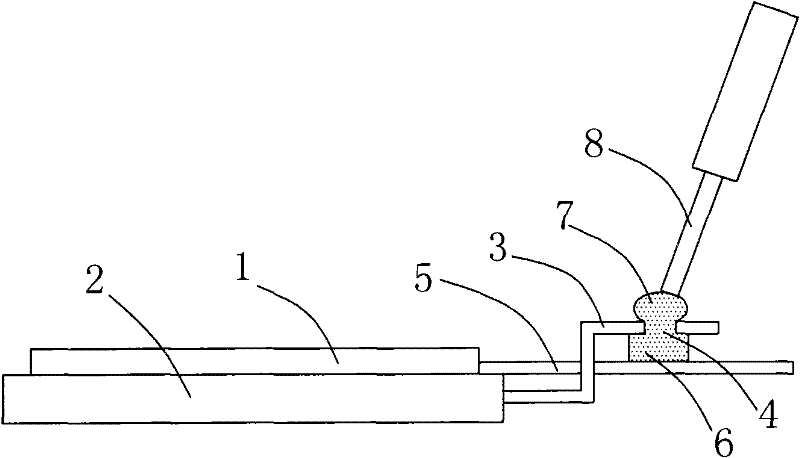

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

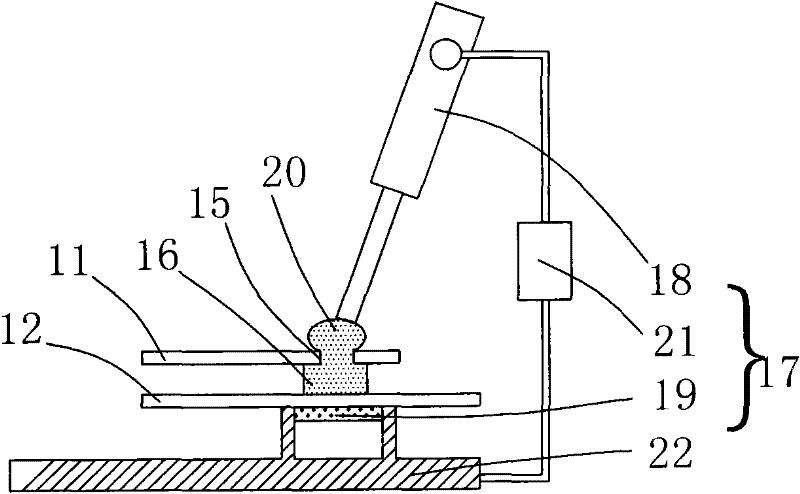

[0021] See image 3 , image 3 Shown is a schematic diagram of the combination of the welding device and the circuit board according to the present invention. The welding device of the present invention is used for welding the first circuit board 11 and the second circuit board 12 that are arranged oppositely. In this embodiment, the first circuit board 11 The second circuit board 12 may be a flexible printed circuit board (FPC). The first circuit board 11 has a solder hole 15, the second circuit board 12 has a solder joint corresponding to the solder hole 15 on a side close to the first circuit board 11, and the solder joint has a second solder 16.

[0022] The soldering device 17 includes a soldering iron 18 and a heating device 19. The soldering iron 18 is used to dip the first solder 20 into the solder hole 15. The heating device 19 is arranged on a side of the second circuit board 12 away from the first circuit board 11 and corresponds to the second solder 16. In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com