Method for modeling seamless acoustic transmission channel of periodic drill rod

A technology of transmission channel and modeling method, which is applied in the modeling field of seamless acoustic wave transmission channel, can solve the problems of unsatisfactory transmission effect and poor versatility, and achieve the effect of strong applicability, good versatility and reliable transmission results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

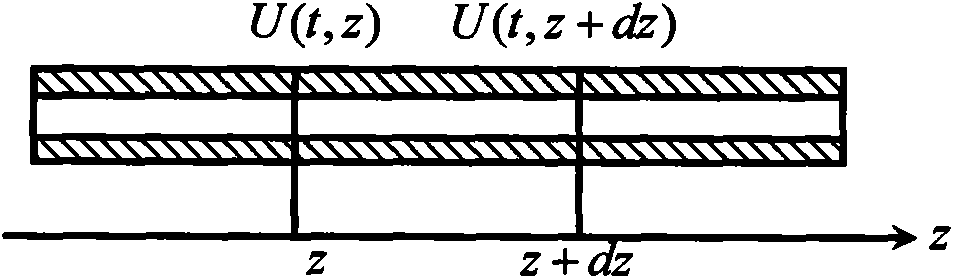

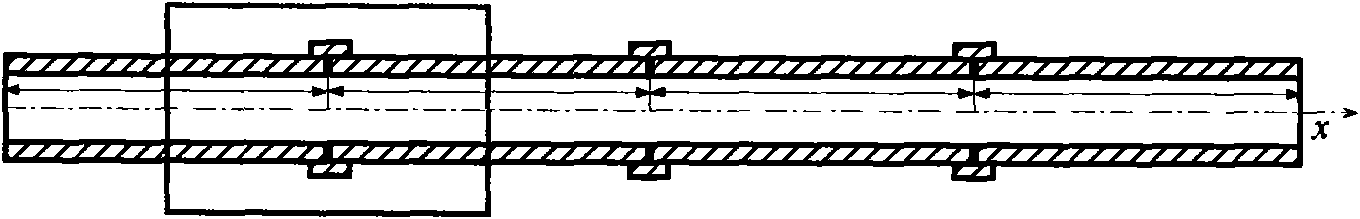

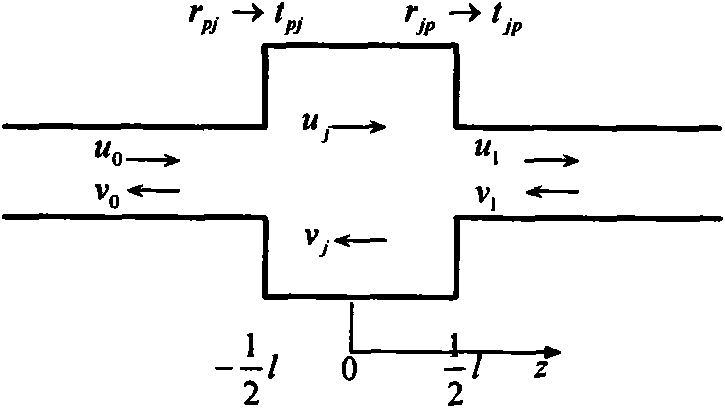

[0125] Two, embodiment 1: drill pipe

[0126] The frequency response parameters of multiple uniform oil pipes are already known. For example, the parameters of five uniform oil pipes are as follows:

[0127] Table 1. Drill string parameters.

[0128]

[0129] Douglas S.Drumheller and Thomas G.Barnes respectively used finite difference and characteristic equations to give the frequency response of sound waves propagating in oil pipes, and found that when sound waves propagate in periodic oil pipes, they have frequency passband and forbidden band characteristics, and their frequency response Curves are similar to comb filters, see Figure 7 right picture. Figure 7 The figure on the left shows the transmission characteristics calculated with the seamless acoustic wave model proposed by the present invention. It can be seen that under the same conditions, the two models have obtained the same results, but the present invention has more advantages than it. The present inven...

Embodiment 2

[0132] 3. Embodiment 2: oil pipe

[0133] The modeling method of the present invention will be further described below through the calculation of the sound path characteristics of the drill pipe under different drilling tool combinations.

[0134] The tubing has two structures:

[0135] tubing type

Inner diameter mm

Outer diameter mm

cross-sectional area

length m

[0136] m 2

big tubing

151.52

178

0.0274

9

small tubing

151.52

178

0.0274

1.55

[0137] There are also two types of couplings, one of which is a joint that exists in the middle of a small tubing:

[0138]

Coupling type

Inner diameter mm

Outer diameter mm

cross-sectional area

m 2

length m

151.52

203

0.0573

0.13

middle of small tubing

connector

151.52

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com