Avalanche commutation diode special for 16000A/200-400V welding machine and preparation method thereof

A technology of rectifying diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of small capacity of rectifying diodes, parallel current sharing, etc., to ensure reliability, reduce power consumption, and improve current expansion effect of ability

Active Publication Date: 2011-01-05

JINZHOU SHENGHE POWER ELECTRONICS

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the contradiction that the current rectifier diode dedicated to a single electric welding machine has a small capacity and needs to be connected in parallel for current sharing in the use of the device, and to provide a current expansion Avalanche rectifier diode dedicated to 16000A / 200-400V electric welding machine with stronger capability, larger capacity, better quality, higher reliability and lower use cost and its manufacturing method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

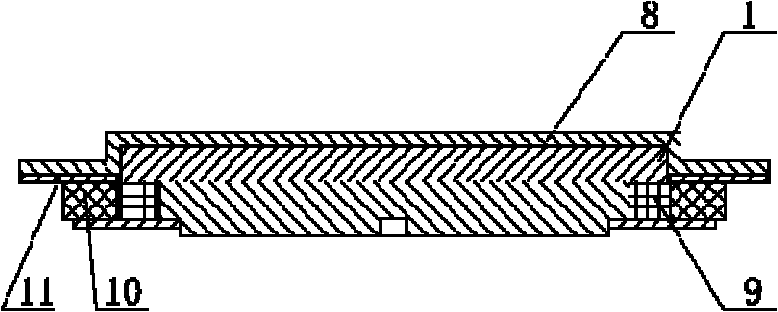

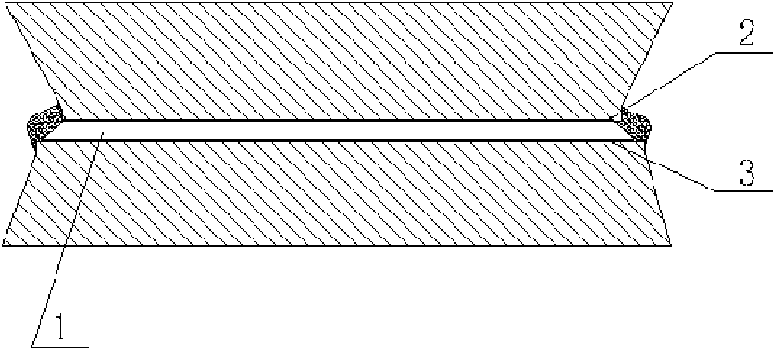

The invention relates to an avalanche commutation diode special for a 16000A / 200-400V welding machine and a preparation method thereof. The invention solves the problems that an avalanche commutation diode special for a single welding machine has small capacity and that parallel connection and flow equalization are needed during the use of the avalanche commutation diode. An N-type (100) radial single crystal silicon piece, which has specific resistance Rho n of 5-10 Ohm-cm, diameter of 70 mm and thickness of 0.17-0.19 mm, is adopted; at the temperature of 1250 DEG C, double-surface once diffusion is carried out; the surface concentration of a surface higher-concentration region of a diffusion region is 0.06-n A, a junction depth X jP is 58-62 microns, and residual minority carrier lifetime Tao p of a base region is 9-13 Mu S; cathode-anode titanium-nickel-gold undergoes ohmic contact; a cathode table surface undergoes spray sand molding, corrosion, cleaning, passivation protection andintermediate test; and a shell is arranged, the thickness of a pipe is 5-6 mm, cold pressure welding packaging is conducted under the protection of nitrogen gas, and the thickness of the pipe is 5-6mm after the packaging. The avalanche commutation diode has stronger current expansion capability, larger capacity, better quality, higher reliability and lower use cost.

Description

16000A / 200-400V welding machine dedicated avalanche rectifier diode and its manufacturing method technical field The invention relates to a power semiconductor device, in particular to a special avalanche rectifier diode for 16000A / 200-400V electric welding machine and its manufacturing method. Background technique At present, rectifier diodes for welding machines are mainly Φ63mm / 13500A / 200-400V rectifier diodes produced abroad and Φ48mm / 7000A / 200-400V rectifier diodes produced domestically. Their manufacturing method is to use N-type (111) radial low-resistance single crystal, first perform double-sided diffusion, then grind one side, and then perform single-sided diffusion. As the diameter of the silicon wafer increases, the deformation becomes more and more serious. Not only the diameter of the silicon wafer is too large, but also the thickness cannot be thinner. It is not easy to have a thickness of 63mm, a diameter of 0.21mm, and a capacity of 13500A. Increasing the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L29/861H01L29/04H01L29/06H01L29/16H01L21/22H01L29/45H01L21/329

Inventor 夏吉夫郭永亮潘福泉潘峰

Owner JINZHOU SHENGHE POWER ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com