Method and system for monitoring fuel ratio of blast furnace in real time

A technology of real-time monitoring and fuel ratio, applied in general control system, control/regulation system, multiple fluid ratio control, etc., can solve the problem of poor grasp of the best timing and degree of coal injection volume adjustment, and poor uniformity of operator operation , inaccurate calculation of material rate and fuel ratio, etc., to achieve the effect of reducing operation randomness, reducing blast furnace fuel consumption, and standardizing operation behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

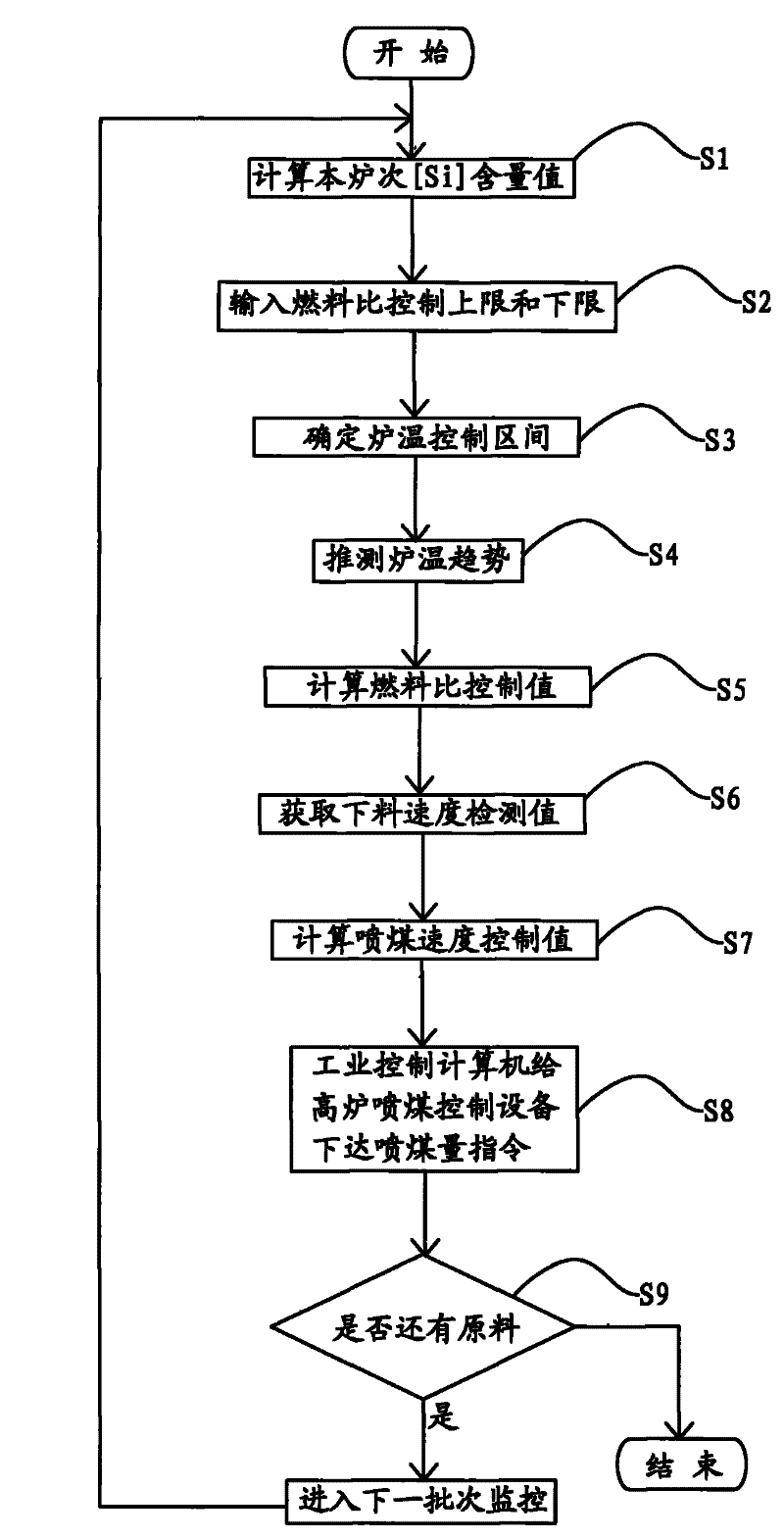

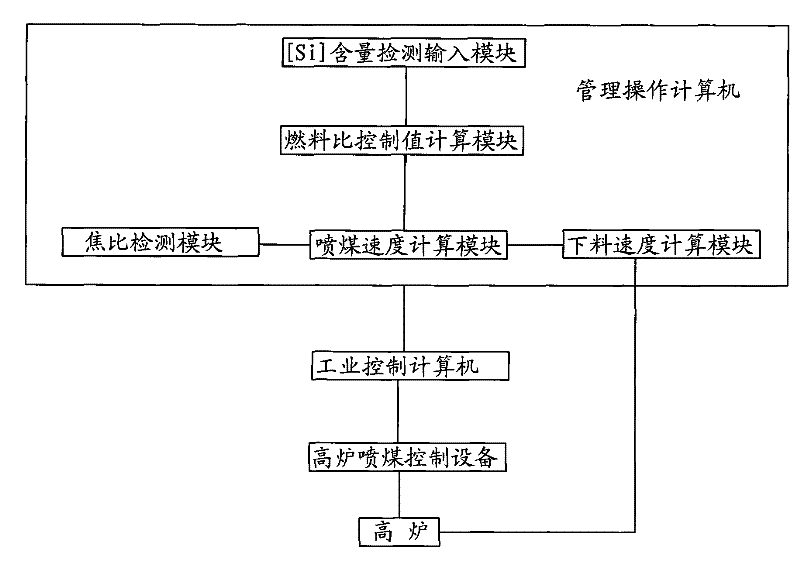

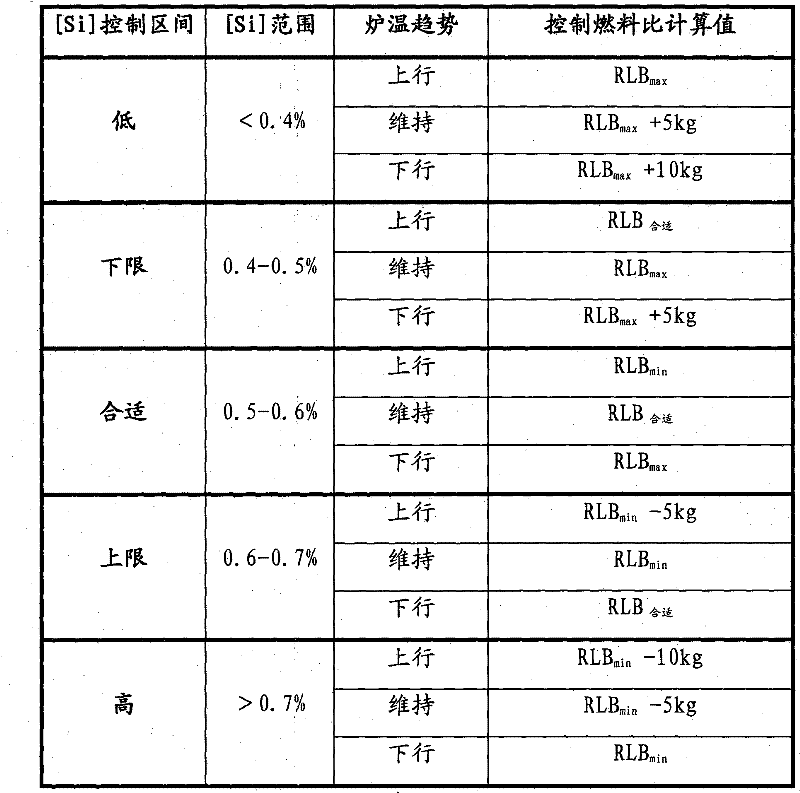

[0029] see figure 1 , step S1, the operator calculates the detected value of [Si] content in molten iron, and inputs the management operation computer through manual or network input before the iron tapping ends, can adopt fluorescence detector to detect [Si] content, also can adopt other known technology, in This will not be repeated here. Step S2, the operator sets the fuel ratio control upper limit RLB according to furnace conditions max with the lower control limit RLB min Enter the management operation computer, and calculate the RLB 合适 =(RLB max +RLB min ) / 2. Step S3, determining the furnace temperature control interval, the operator presets the molten iron [Si] into five control intervals in the computer, [Si]max , lower limit RLB min 、RLB 合适 Look up Table 1 to calculate the fuel ratio control value RLB.

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com