Energy-saving stove

A stove and stove ring technology, which is applied to household stoves/stoves, stove/stove tops, and household stoves, etc., can solve the problems of low efficiency and large heat loss of stoves, and achieve the effect of high thermal efficiency and less heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

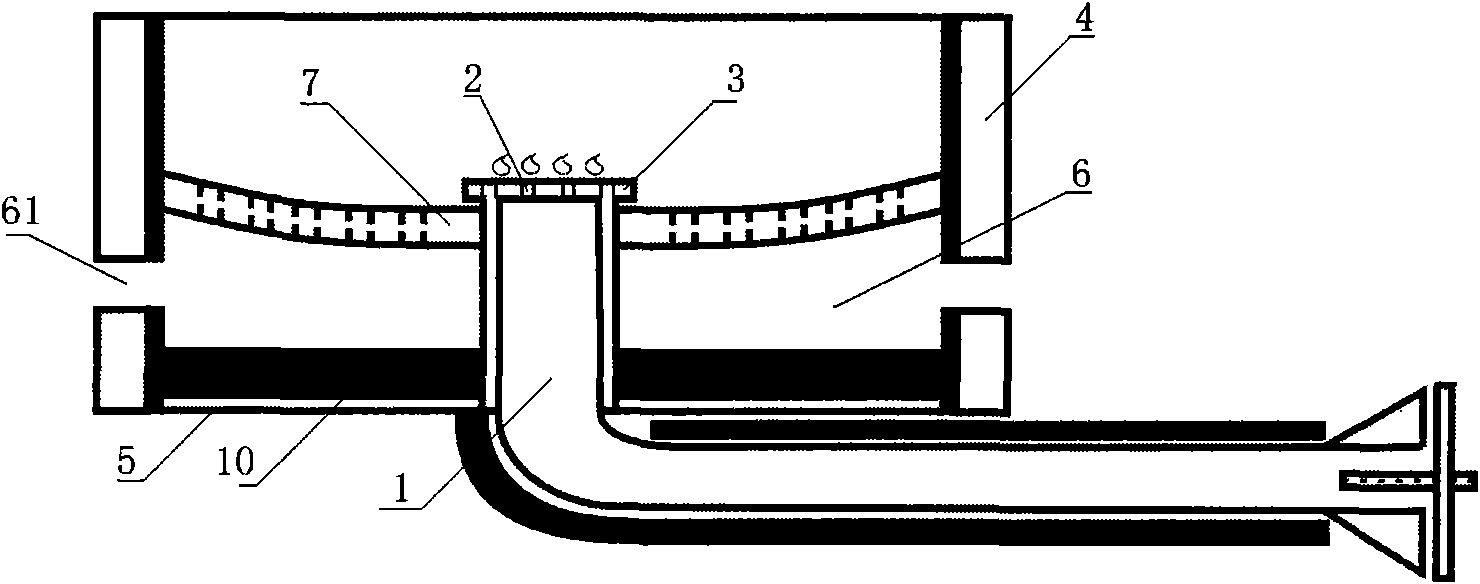

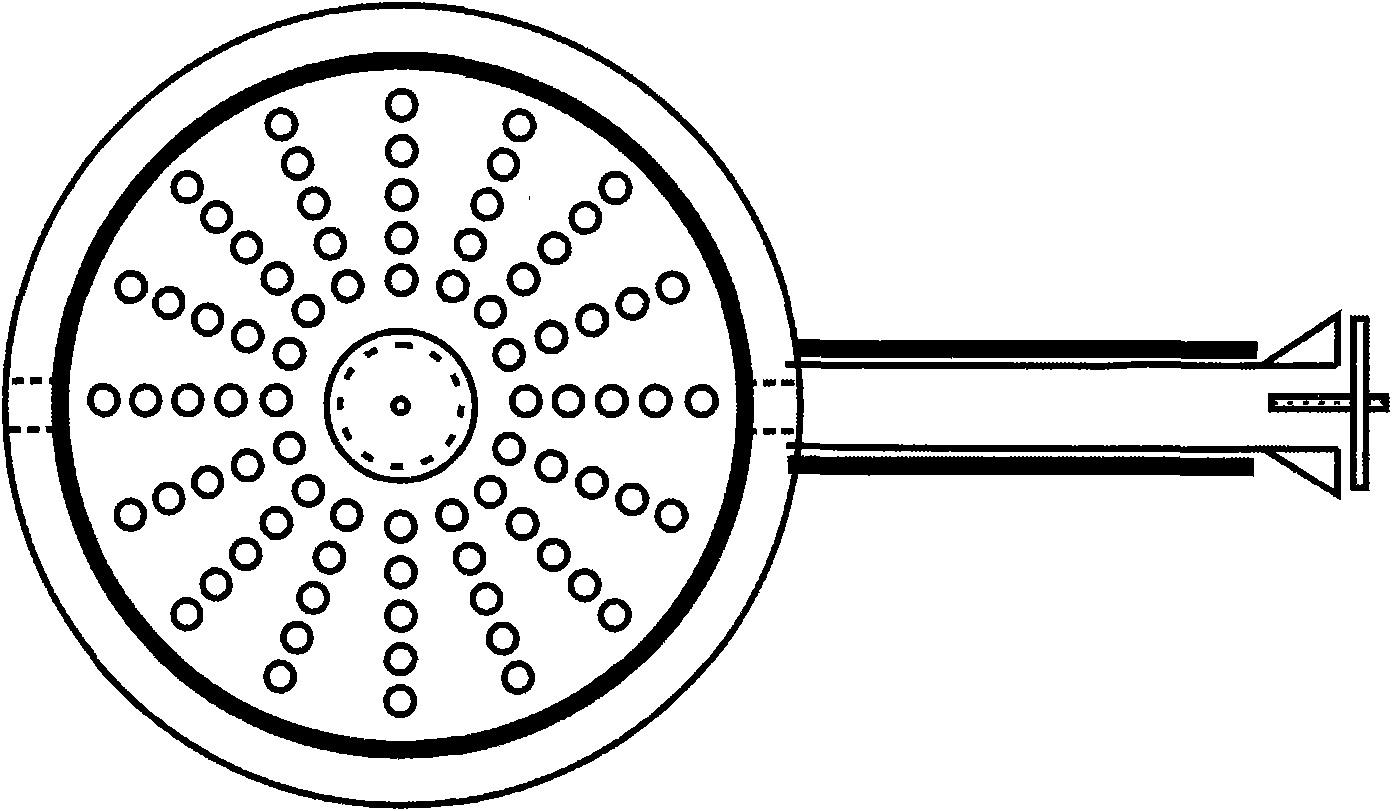

[0040] refer to figure 1 , Picture 1-1

[0041] The energy-saving stove includes a mixing chamber for combustible gas and air. The mixing chamber 1 communicates with the nozzle hole 2 on the combustion head. The combustion head 3 is set in the furnace 6 surrounded by the furnace ring 4 and the furnace bottom 5. The furnace ring 4 has a shape that can cooperate with the pot body and the furnace bottom 5 to form a closed furnace 6. The closed furnace 6 has a flue gas outlet 61, and the combustion head 3 and the flue gas lead A flue gas flow path is formed between the outlets; a porous heat storage radiation plate 7 is blocked on the flue gas flow path.

[0042] The position of the smoke outlet 61 is lower than the combustion head 3 , and the heat storage radiation plate 7 is higher than the smoke outlet 3 and lower than the combustion head 3 .

[0043] The furnace ring 4 and the furnace bottom 5 are lined with a heat insulating material layer. The said fuel of the present i...

Embodiment 2

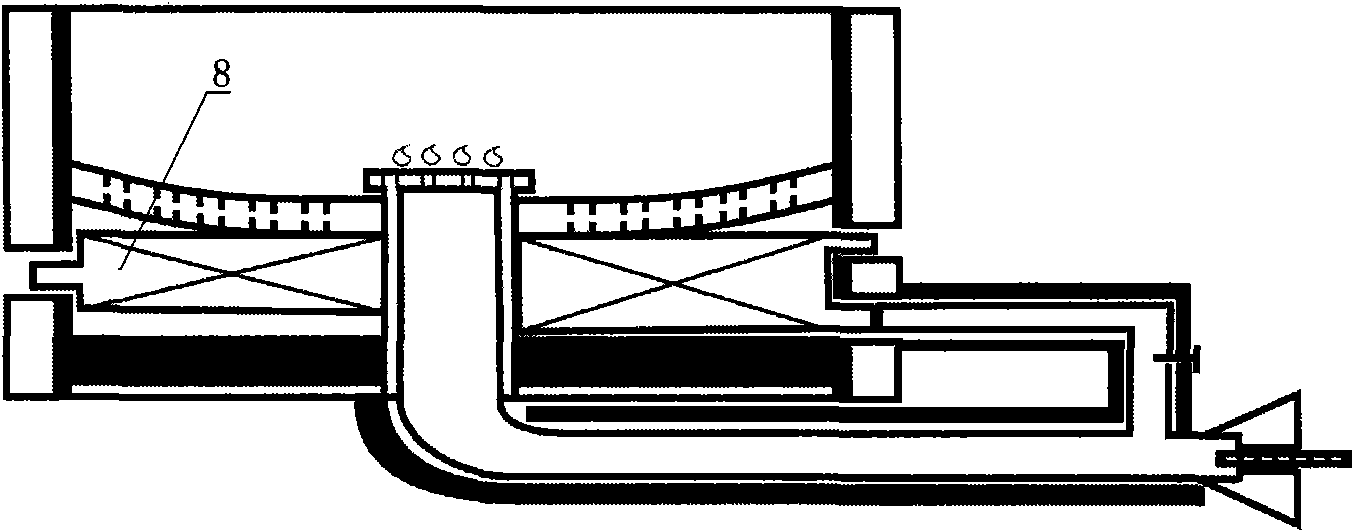

[0045] refer to figure 2 , diagram 2-1

[0046] The difference between this embodiment and the first embodiment is that the exhaust gas drawn out through the flue gas outlet 61 exchanges heat with the air that will enter the mixing chamber 1 through the heat exchanger 8 .

[0047] The heat exchanger 8 is arranged in the furnace 6 .

Embodiment 3

[0049] refer to image 3 , Figure 3-1

[0050] The difference between this embodiment and the second embodiment lies in that: the heat exchanger 8 is arranged in the furnace hoop 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com