Fuel cell humidifier

A fuel cell and humidifier technology, applied in fuel cells, fuel cell additives, electrochemical generators, etc., can solve the problems of high energy consumption, excessive humidification, large membrane area and number of sheets, etc., and achieve low energy consumption , fast humidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described in detail through the following examples in conjunction with the accompanying drawings, but are not limited to the content of this example.

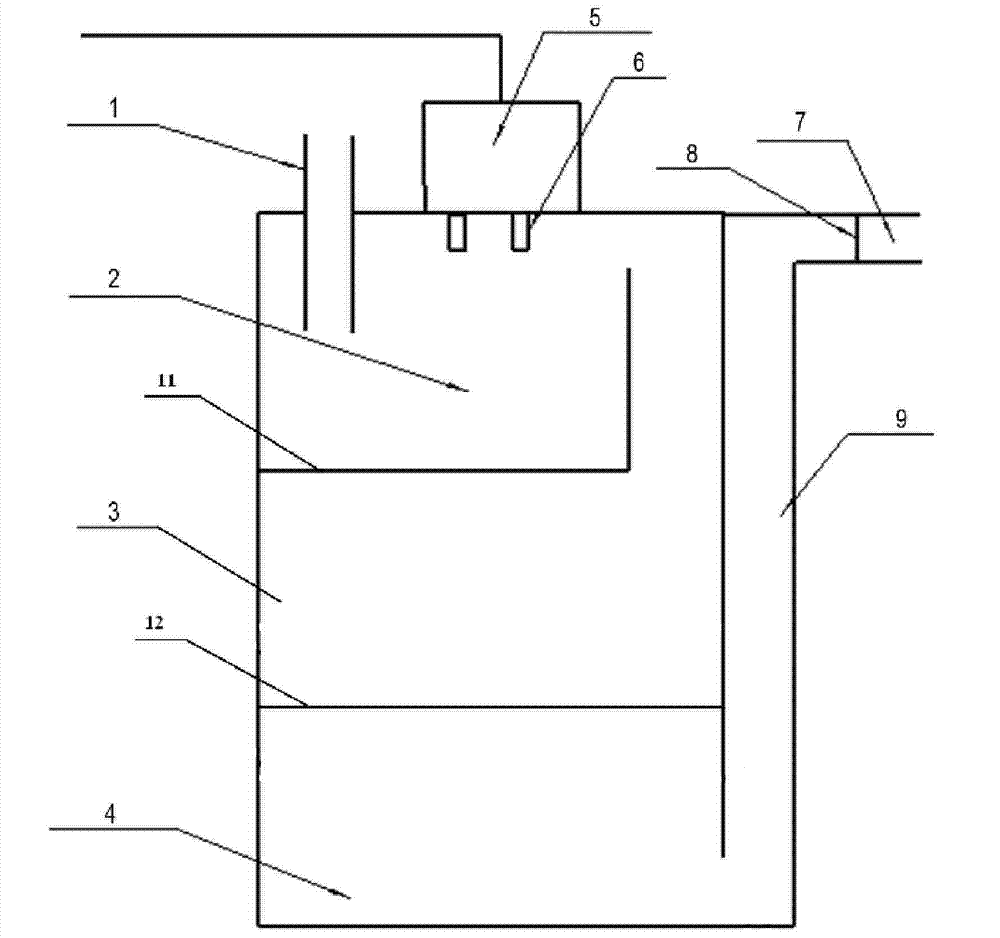

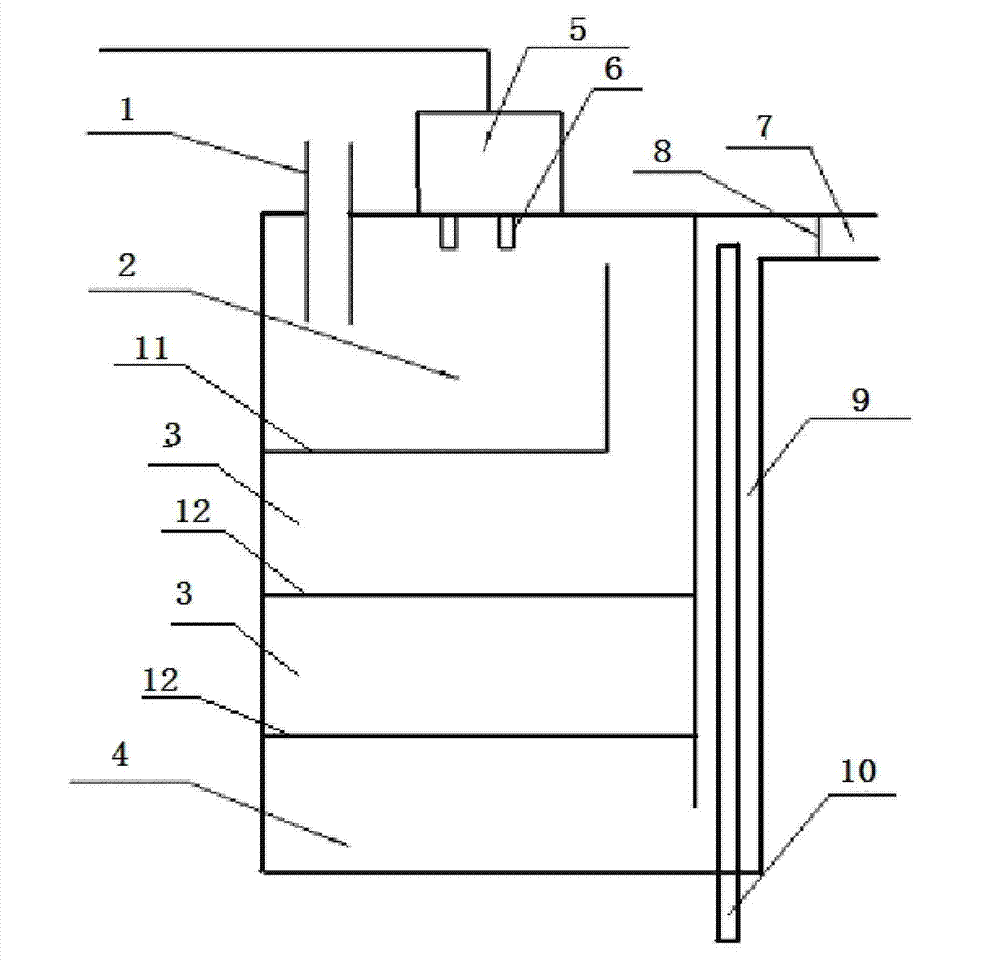

[0022] Such as figure 1 , figure 2 As shown, a fuel cell humidifier includes a gas-liquid exchange area 2, a heat exchange area 3 located at its lower part, and a nozzle control area 5 located at its upper part, wherein the upper part of the gas-liquid exchange area 2 is provided with a gas inlet 1. The heat exchange area 3 communicates with the lower part of the gas outflow part 9, and the gas outlet 7 is provided on the upper part of the gas outflow part 9.

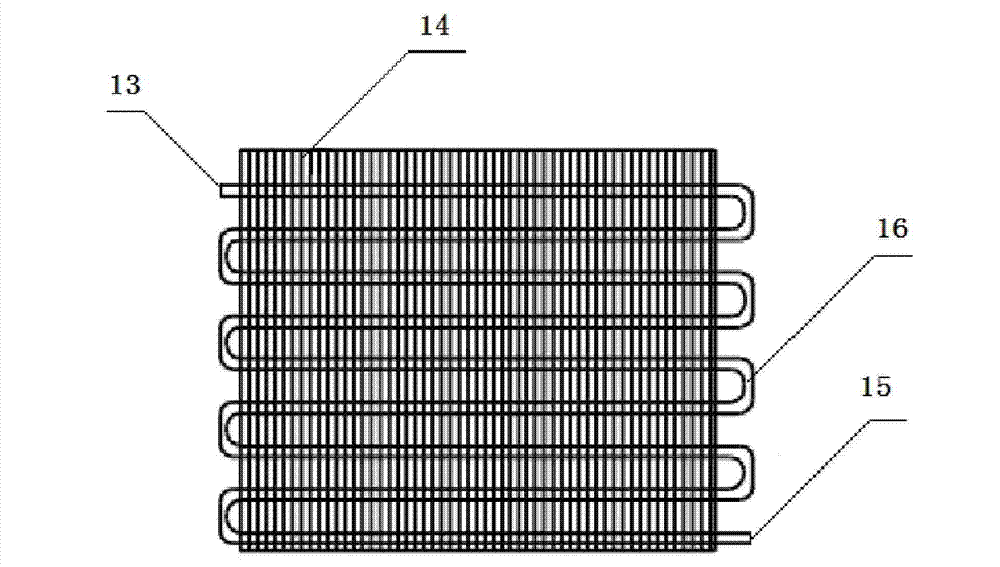

[0023] The gas-liquid exchange area 2 is provided with a porous sieve plate 11, and the nozzle control area 5 is provided with a combination nozzle 6, and its flow rate can be manually controlled by switching nozzles of different apertures and adjusting water pressure, or by a solenoid valve. Take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com