One-time programming memory and manufacturing method thereof

A manufacturing method and memory technology, applied in the field of microelectronics, can solve the problems of read crosstalk, 1R structure integration limitation, increase design complexity and cost, etc., and achieve the effect of eliminating influence, facilitating integration and use, and suppressing read crosstalk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

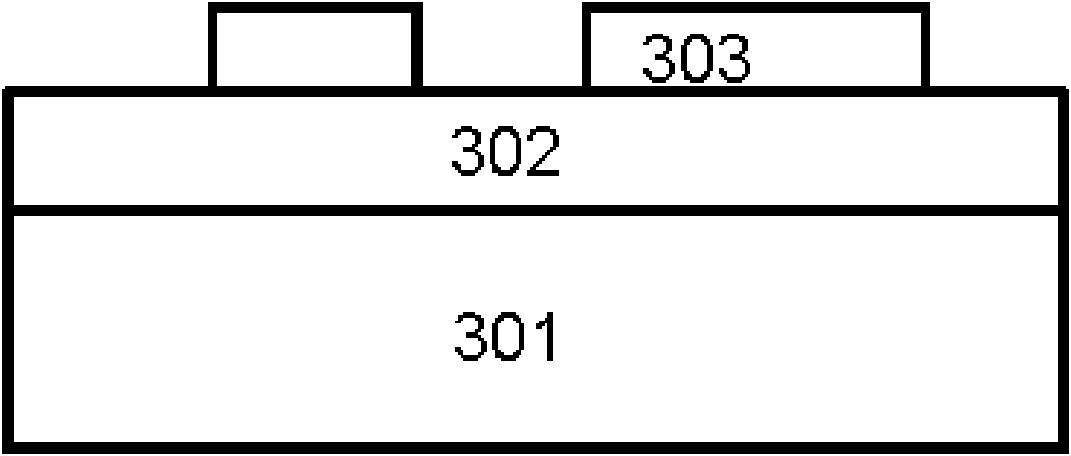

[0033] see image 3 , the embodiment of the present invention proposes a one-time programming memory device that can be integrated with a cross-array structure and has a rectification function. The one-time programming memory includes:

[0034] lower electrode 301;

[0035] upper electrode 303; and

[0036] The functional layer film 302 is located between the upper electrode 303 and the lower electrode 301 .

[0037] The upper electrode 303 and the lower electrode 301 are made of Pt, Ag, Pd, W, Ti, Al, Cu, TiN, ITO, IZO, YBCO, LaAlO 3 , SrRuO 3 and any material in polycrystalline Si. In this embodiment, the upper electrode 303 uses Pt, and the lower electrode 301 uses n + Si.

[0038] The functional layer film 302 adopts NiO, TiO x , CuO x , ZrO x , TaO x , AlO x , CoO, HfO x 、MoO x , ZnO, PCMO, LCMO, SrTiO 3 , BaTiO 3 , SrZrO and any one of amorphous silicon materials. Functional layer film 302 adopts ZrO in the present embodiment2 . In addition, the function...

Embodiment 2

[0045] see Figure 5 , the embodiment of the present invention also provides a method for manufacturing a one-time programming memory, including the following steps:

[0046] Step 501: forming a substrate as a lower electrode;

[0047] In specific production practice, the substrate as the lower electrode can be formed by chemical vapor deposition process, sputtering process, atomic layer deposition process, thermal evaporation process, pulsed laser deposition process or electron beam evaporation process;

[0048] Step 502: forming a functional layer film on the substrate;

[0049] In specific production practice, the functional layer can be formed on the substrate by sputtering process, atomic layer deposition process, spin coating process, pulsed laser deposition process, low pressure / plasma enhanced chemical vapor deposition process or electron beam evaporation process film;

[0050] Step 503: Carry out photolithography and deposit conductive material on the functional la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com