Breaking apparatus for membraniform adhesive and breaking method thereof

An adhesive, film-like technology that can be used in the manufacture of fine work equipment, electrical components, semiconductor/solid-state devices, etc., and can solve problems such as adhesion, low production efficiency, and hardening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

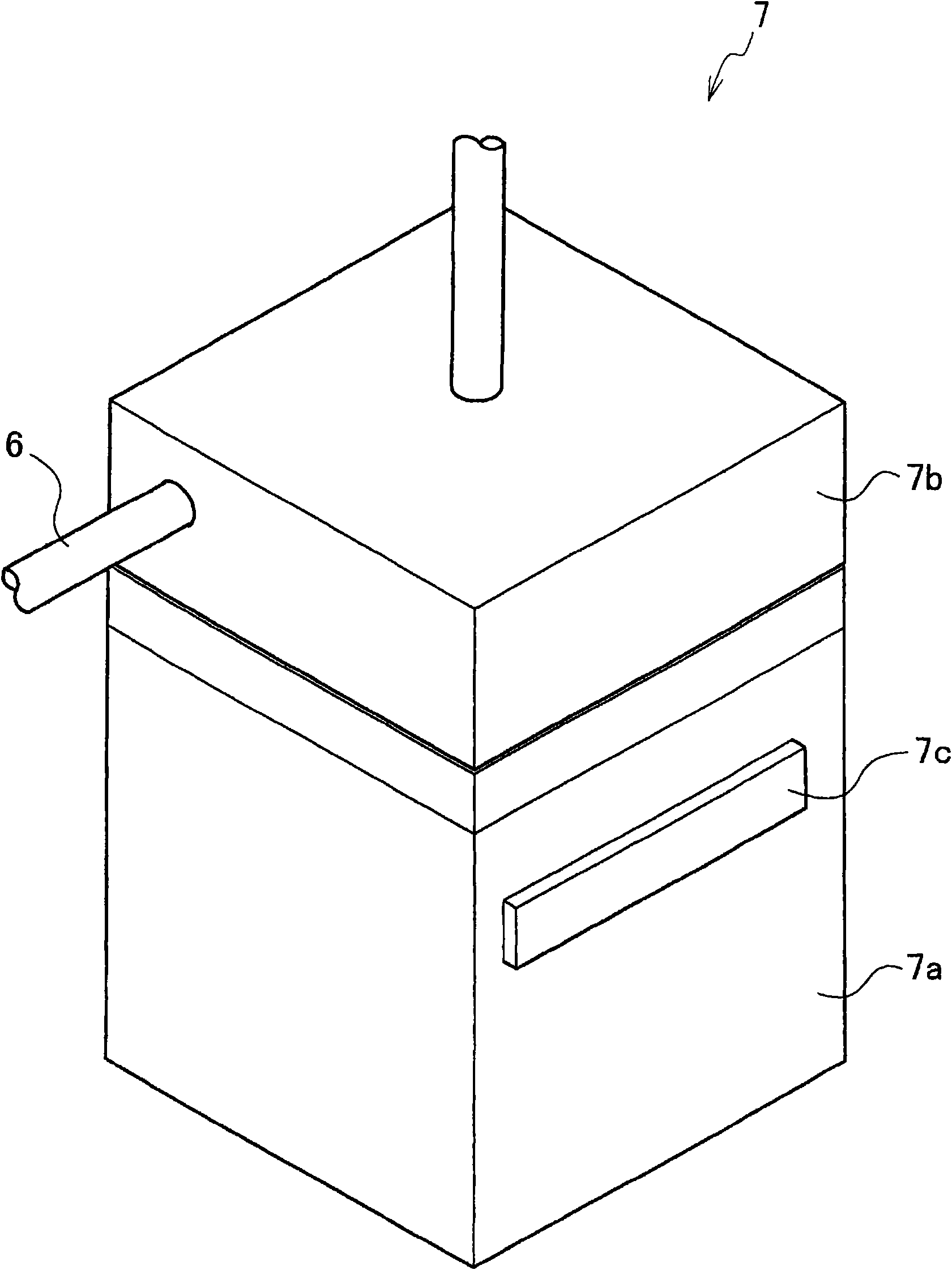

[0040] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings. First, a breaking device according to a first embodiment of the present invention will be described. figure 1 It is an exploded perspective view showing the structure of the breaking device of this embodiment, figure 2 It is a perspective view showing its appearance. also, image 3 It is a perspective view showing the state of the film-like adhesive to be broken.

[0041] Such as figure 1 and figure 2 As shown, the breaking device 1 of this embodiment is used to break the film adhesive 10 attached to the back surface of the wafer 11 in the state attached to the protective tape 13 attached to the opening of the ring frame 12. 12a on. In addition, the breaking device 1 at least includes: a frame holding member 2 for holding the ring-shaped frame 12; an expansion member 3 for expanding the protection band 13; The cooling means 6 for cooling the film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com