Method for improving fatigue strength of bolt through combination of bolt and connecting piece material

A fatigue strength and connector technology, applied in the field of mechanical parts, can solve the problems of large incomplete contact, easily damaged bolts and nuts, fatigue strength reduction, etc., to increase fatigue strength, firm connection force, and enhance the ability to withstand stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

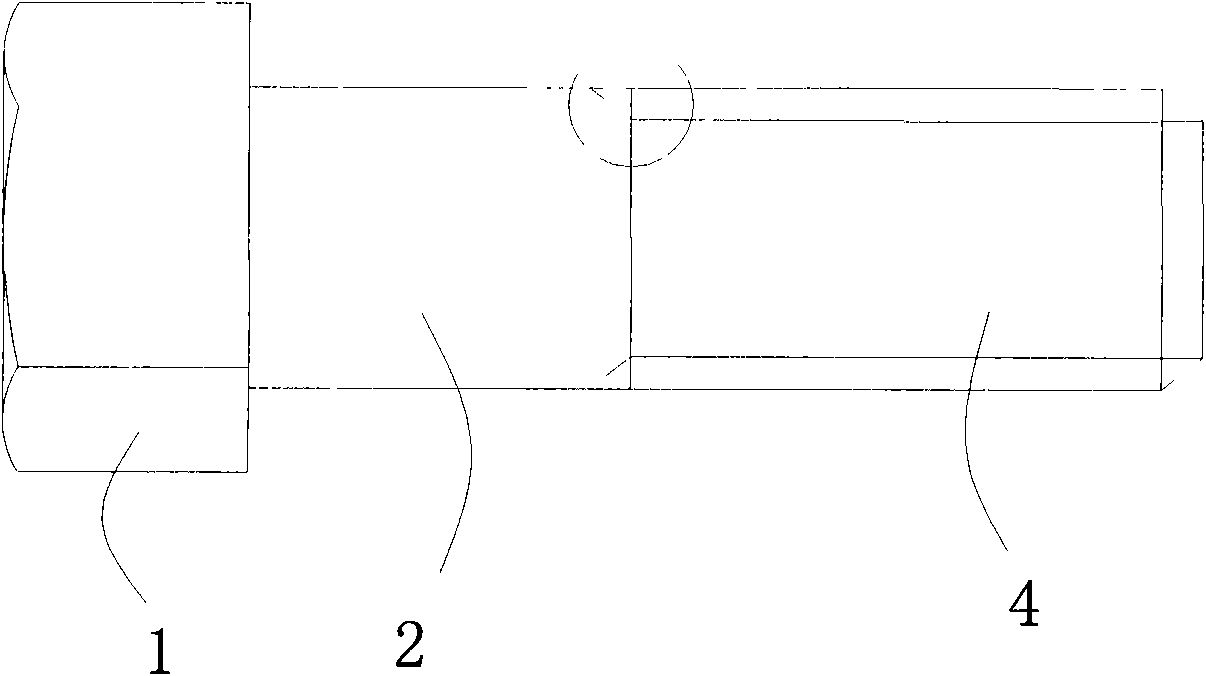

[0013] Embodiment 1: as figure 1 , 2 as shown,

[0014] The bolt includes a bolt head 1, a bolt cylindrical part 2 and a threaded part 4. The threaded part 4 is composed of an incomplete threaded part 3, a thread tooth removal part 5 and a complete threaded part. The threaded part is obliquely removed from the root of the thread. Part of the frustum-shaped thread removal part 5 is formed. From the minimum diameter of the frustum-shaped thread part to the cylindrical part, the diameter is slowly expanded in an arc shape to form an incomplete thread part 3. The cylindrical part of the bolt is selected according to the thickness of the connected body. When the bolt is screwed with the nut, in order to adjust the nut to the best position, a gasket can be used if necessary to obtain a good screwed state. At this time, the nut is usually 50%-80% of the total length of the bolt. The frustum-shaped thread removal portion 5 is screwed together.

[0015] Comparison results of materia...

example 2

[0019] Example 2: The bolt includes a bolt head 1, a bolt cylindrical part 2 and a threaded part 4. The threaded part 4 is composed of an incomplete threaded part 3, a thread tooth removal part 5 and a complete threaded part. The threaded part is obliquely removed from the root of the thread One part, this part forms a frustum-shaped thread removal part 5, and slowly expands in an arc shape from the smallest diameter of the frustum-shaped thread part to the cylindrical part to form an incomplete thread part 3. The bolt is selected according to the thickness of the connected body When the bolt is screwed with the nut, in order to adjust the nut to the best position, a gasket can be used if necessary to obtain a good screwed state. At this time, the nut usually takes 50%-80% of the total length % is screwed with the frustum-shaped thread removal portion 5 of the bolt.

[0020] Comparison results of material hardness of bolts and nuts, see the table below

[0021]

[0022] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com