Method for improving fatigue strength of bolt and preventing bolt from being damaged

A fatigue strength and bolt technology, applied in the field of mechanical parts, can solve problems such as easy breakage of bolts, and achieve the effect of preventing bolt damage, better effect, and improving fatigue strength

Inactive Publication Date: 2011-01-05

孙中强

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the above problem that the bolts are easy to break, the present invention proposes a method for improving the fatigue strength of the bolts and preventing the bolts from being damaged.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

example 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

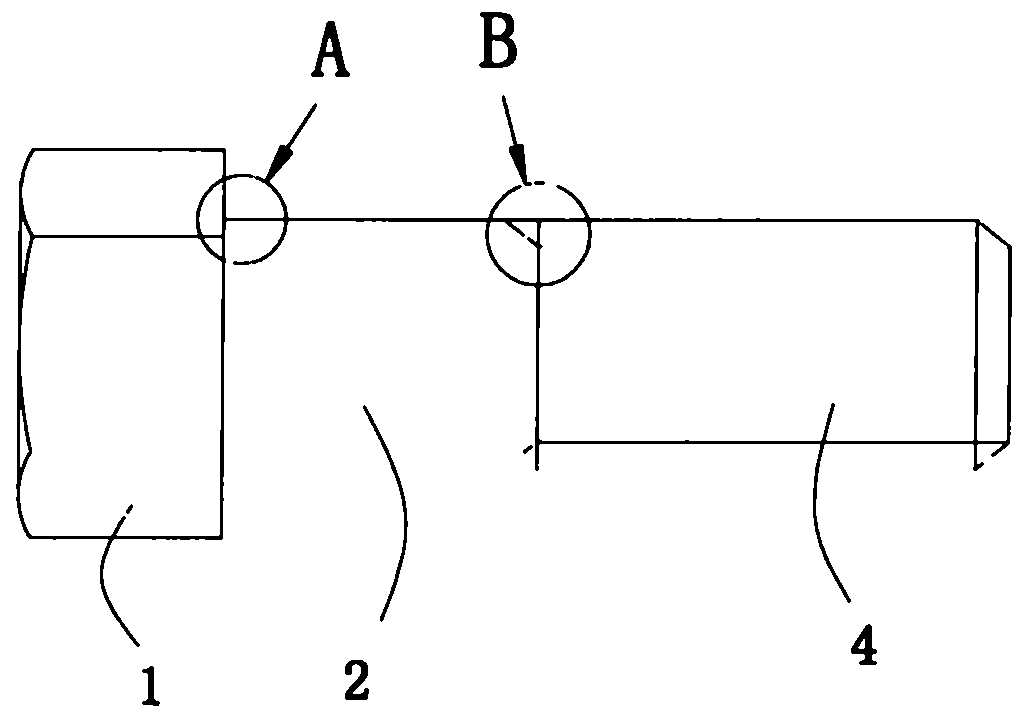

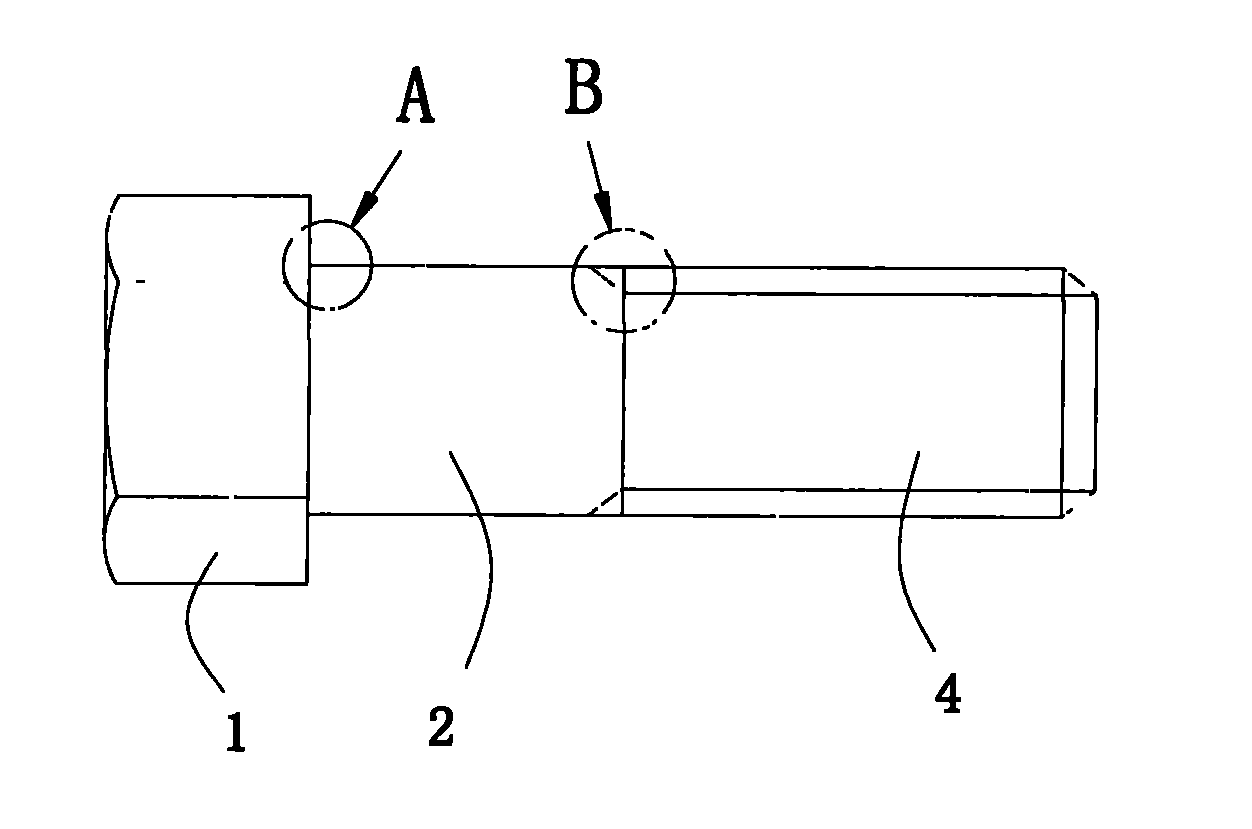

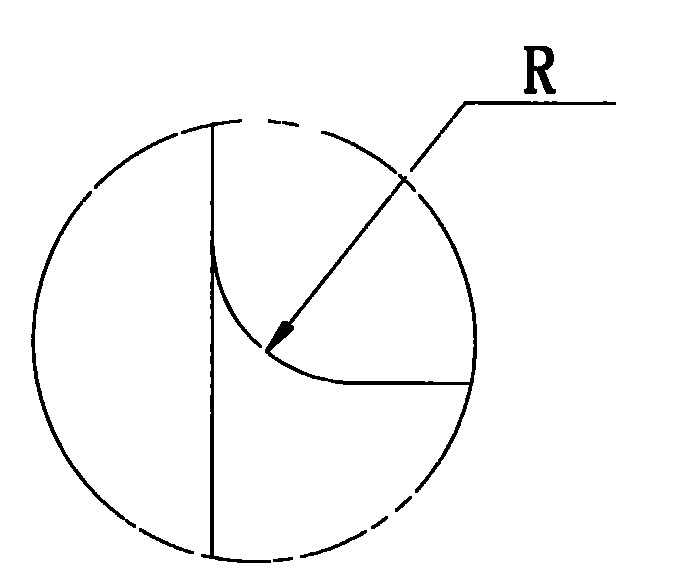

The invention relates to a method for improving fatigue strength of a bolt and preventing the bolt from being damaged, which belongs to the technical field of machine parts. The method comprises the following steps: performing plastic working by using the bolt consisting of a bolt head, a bolt cylindrical part, an incomplete threaded part, a thread tooth removing part and a complete threaded part;enlarging the semidiameter R of the crown face of a joint of the bolt head and the bolt cylindrical part; and using impact force to perform partial plastic working on the crown face of the joint of the bolt head and the bolt cylindrical part. The method enlarges the semidiameter R of the crown face of the joint of the bolt head and the bolt cylindrical part so that stress concentration can be reduced, and performs the plastic working through steel ball impact so that the structure is more micronized and generates compression residual stress, thus the service life of the bolt is improved by 20to 50 percent, and simultaneously, the fatigue strength is improved and the bolt damage is prevented so as to ensure that the bolt can be used for a long time, and the two methods act on the crown face successively so that the effect is better.

Description

Methods of Improving Bolt Fatigue Strength and Preventing Bolt Breakage technical field The invention belongs to the technical field of mechanical parts, in particular to a method for improving the fatigue strength of bolts and preventing bolt damage. Background technique Bolts are widely used in various mechanical equipment, iron bridges, buildings, construction equipment, various transportation machinery, electrical appliances, glasses and other movable parts or joints of components subjected to external vibrations, but bolts will be damaged during long-term use. Damage, the connection between the screw rod and the bolt head is easy to break due to stress concentration or insufficient surface treatment, which makes the hardness too high and the internal structure is thick, which reduces the practical performance of the bolt. Contents of the invention In order to solve the above problem that the bolts are easy to break, the present invention proposes a method for impro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16B33/02F16B35/04F16B31/06

Inventor 西田新一孙中强

Owner 孙中强

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com