Automatic control system for acid cleaning of conductive roller of aluminium foil production line

A control system and production line technology, applied in the field of control systems, can solve problems such as large tension fluctuations in the production line, damage to conductive rollers, and complex and difficult operations, and achieve the effects of low maintenance costs, improved production efficiency, and simple and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

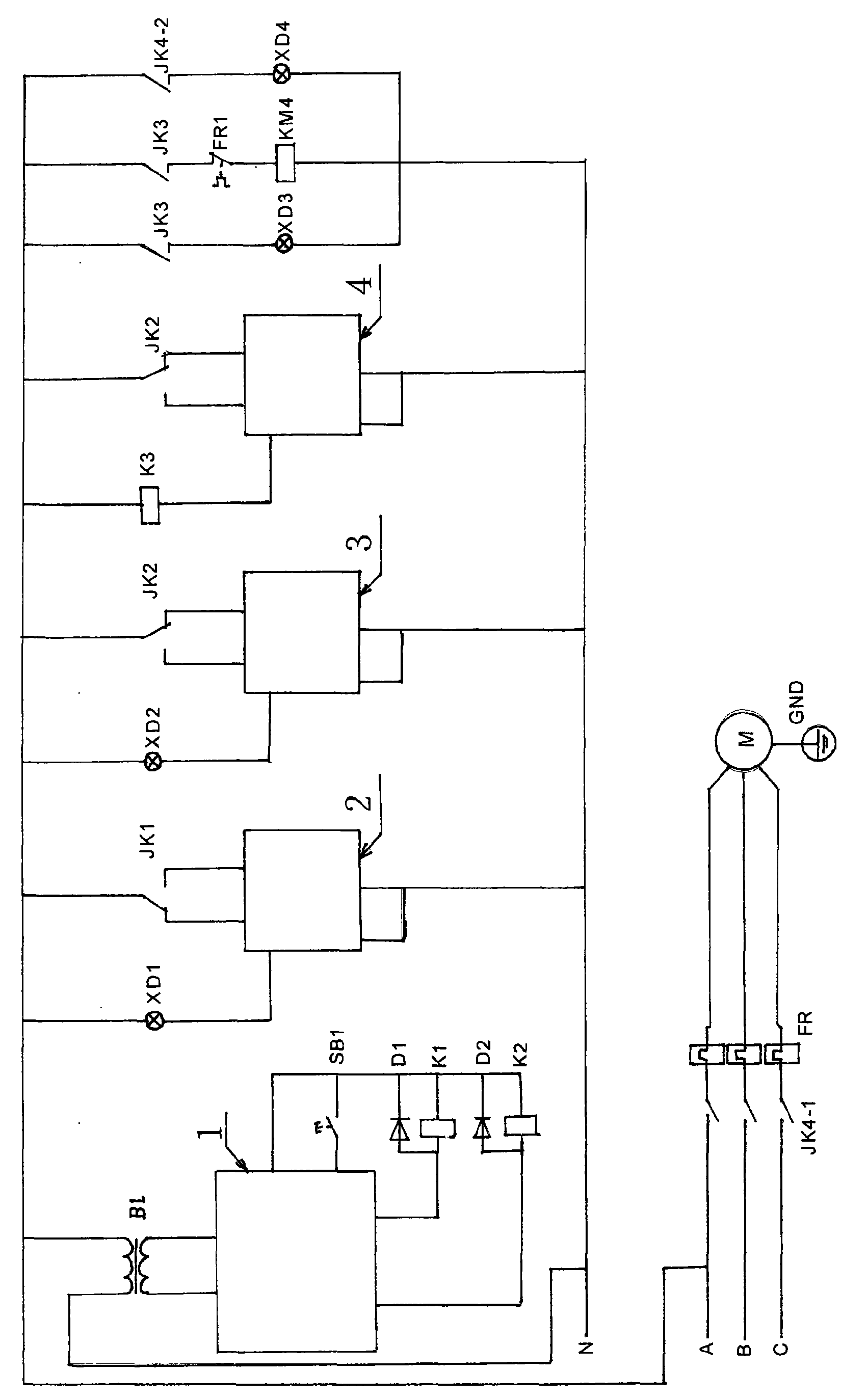

[0017] See figure 1 . figure 1 See the table below for the codes of each component marked in and their corresponding specific names.

[0018] code name

name

code name

name

code name

name

A

Power frequency phase A

D1, D2

JK1

A set of contacts of K1

head

B

Power frequency B phase

XD1

Drain light

JK2

A set of contacts of K2

head

C

Power frequency phase C

XD2

Acid discharge indicator

JK3

A set of contacts of K3

head

B1

Power frequency transformer

XD3

Pickling indicator light

KM4-1

Main contacts of KM4

1

Pickling controller

XD4

pump light

KM4-2

Auxiliary touch of KM4

head

2

Drain el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com