Process for continuously producing corresponding aldehyde by alkene hydroformylation reaction

A technology for the hydroformylation of olefins, which is applied to carbon monoxide reaction preparation, organic chemistry and other directions, can solve the problems of high maintenance costs, low utilization rate of raw materials, and no utilization, and achieves low energy consumption for device operation and utilization of raw materials. High, easy-to-separate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

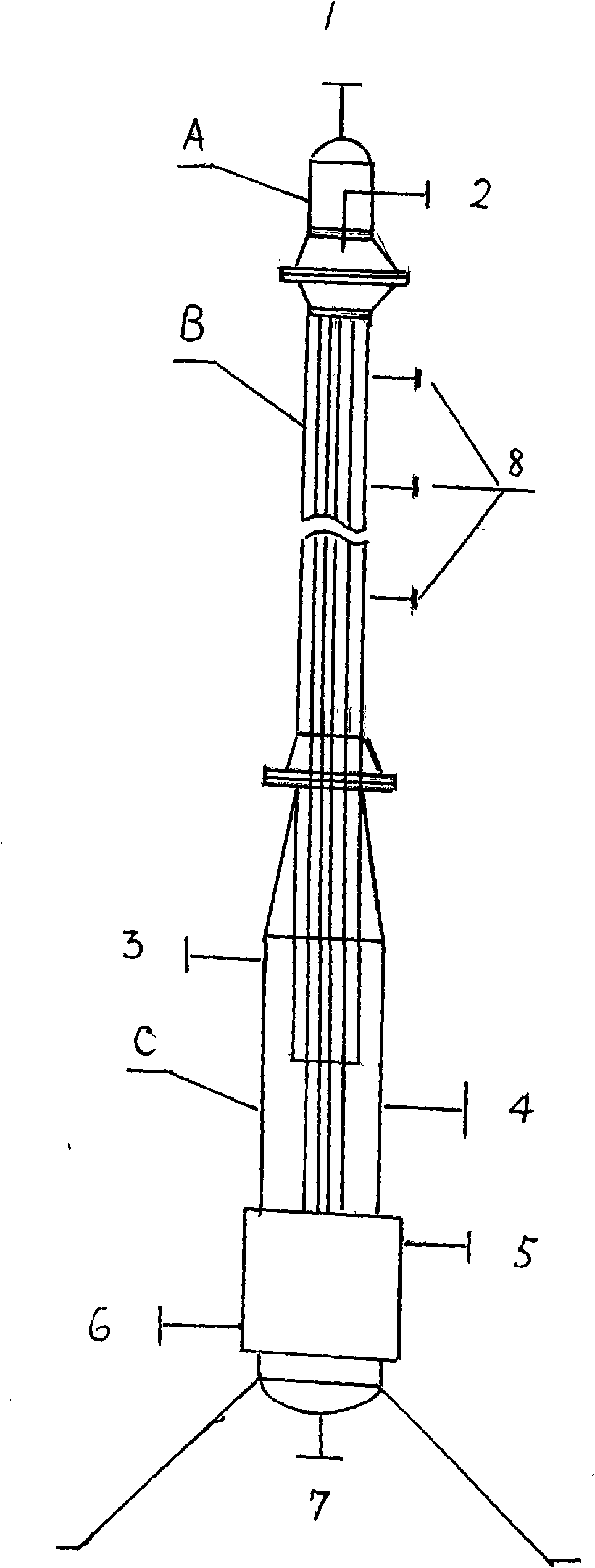

[0026] A kind of technology of ethylene hydroformylation reaction continuous production corresponding propionaldehyde, process flow see figure 2As shown, it is carried out in two stages in two olefin hydroformylation continuous reactors, No. 1 olefin hydroformylation continuous reactor (I), it consists of the gas-liquid distribution section A on the top, the mass transfer reaction in the middle Section B and the lower gas-liquid separation section C are composed of three parts (see Figure 1), and the upper gas-liquid distribution section A has a mixed gas inlet pipe composed of hydrogen and carbon monoxide, a gas distributor 1 and a liquid inlet pipe for the catalyst solution And the liquid distributor 2, the mass transfer reaction section B in the middle is cylindrical, with a diameter of 900mm and a height of 4000mm (excluding the part extending into the gas-liquid separation section C), filled with hydrophilic, 0.01-0.2mm in diameter Fiber membrane composed of metal fibers ...

Embodiment 2

[0029] A kind of technology of isobutene hydroformylation continuous production corresponding isovaleraldehyde, process flow see figure 2 As shown, it is carried out in two stages in two olefin hydroformylation continuous reactors, the equipment is the same as in Example 1, the catalyst and concentration are also the same, the consumption and circulation flow are also the same but the olefin is changed to isobutylene, and the No. 1 olefin Hydroformylation continuous reactor (I) isobutene feed rate is 1260kg / h, the ratio of the amount of material of feed is: isobutene: H 2 : CO=1: 1.2: 1.15, pressure is 4.5mpa, and temperature of reaction is 95 ℃; No. 2 olefin hydroformylation continuous reactor (II) isobutene feed rate is 140kg / h, the ratio of the amount of material of feed Is isobutylene: H 2 : CO=1:1.02:1.02, the pressure is 4.2mpa, the reaction temperature is 95°C, the total yield of isovaleraldehyde in No. 1 and No. 2 olefin hydroformylation continuous reactors: 2.1 tons / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com