Reusable method of decanedioic acid phenol-containing wastewater

A technology for sebacic acid and phenol wastewater, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., and can solve problems such as poor quality of sebacic acid finished products, resin pollution, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

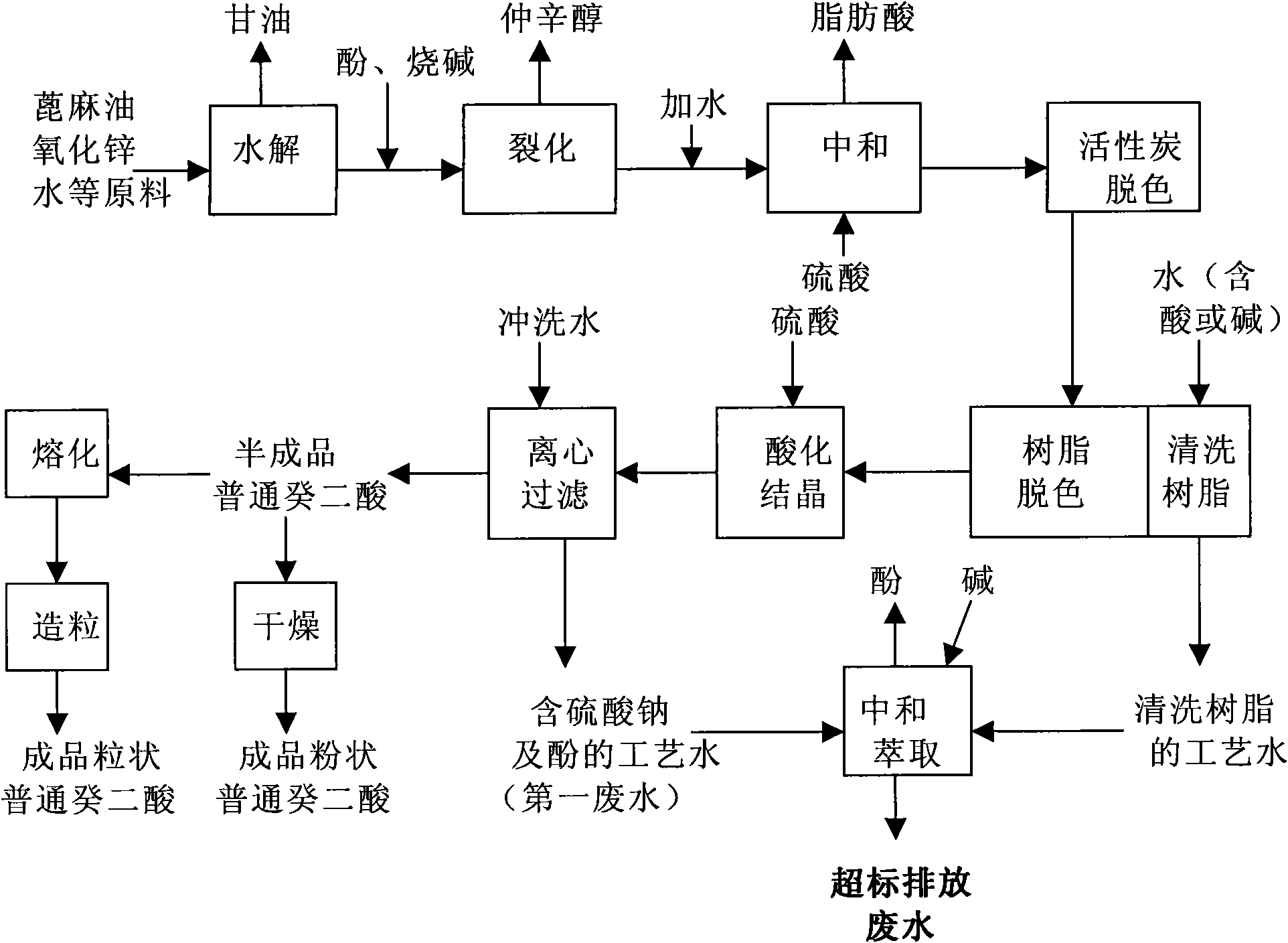

Problems solved by technology

Method used

Image

Examples

Embodiment 1

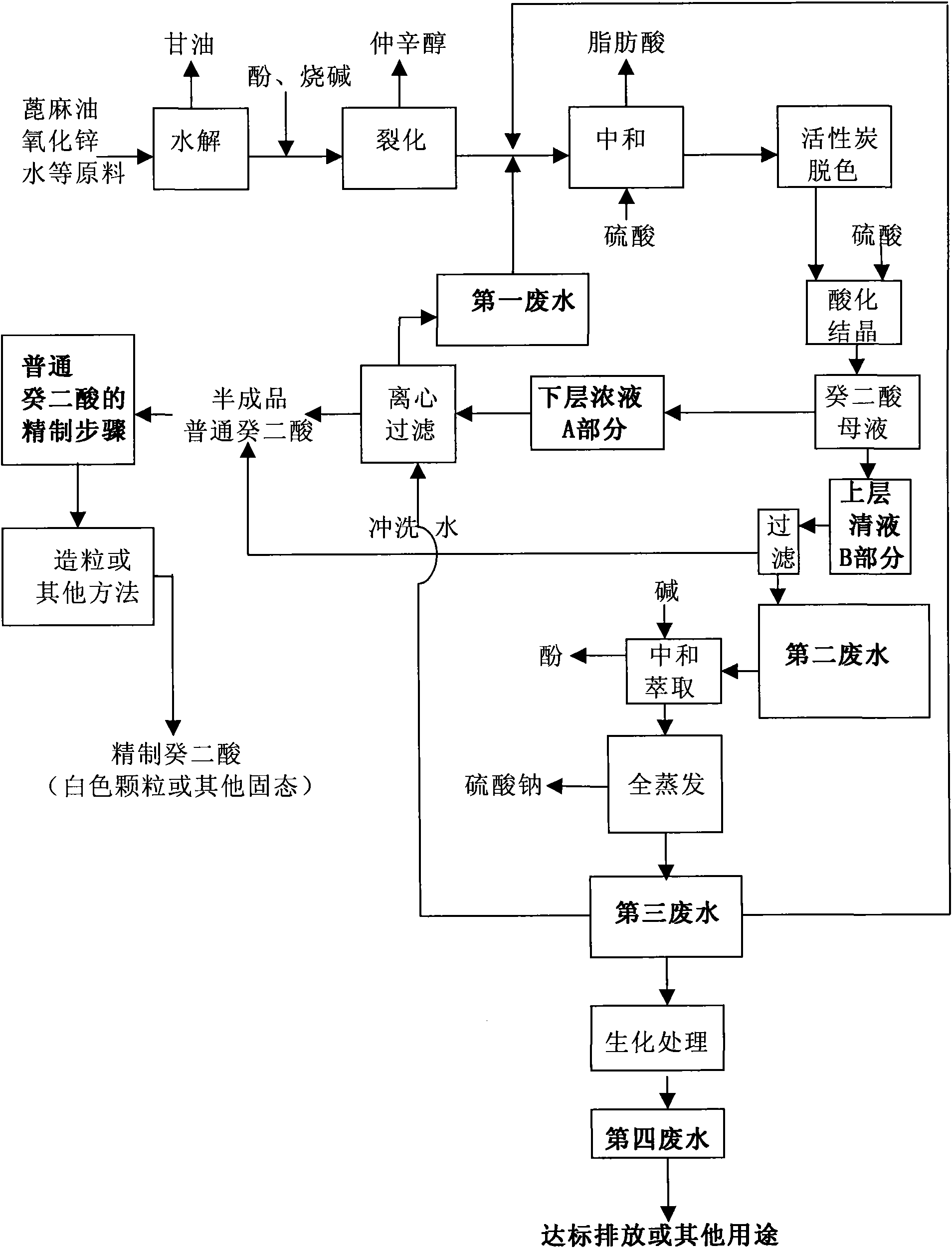

[0116] Such as figure 2 As shown in route a, the raw materials of castor oil, zinc oxide and water are hydrolyzed and cracked to obtain a phenol-containing sebacate solution. The sebacic acid salt solution is neutralized, activated carbon is decolorized, acidified and crystallized to obtain the sebacic acid mother liquor. The sebacic acid mother liquor contains about 4% sebacic acid.

[0117] The sebacic acid mother liquor is subjected to solid-liquid filtration to obtain sebacic acid solids and first waste water, and the first waste water is recycled:

[0118] The resulting 60% by weight of the first waste water is recycled for the neutralization step; the first waste water of the remaining 40% of the uncirculated part is neutralized and extracted to remove phenol, and the pervaporation step is used to remove the sodium sulfate by-product to obtain The third wastewater, the third wastewater is reclaimed for subsequent biochemical treatment to obtain the fourth wastewater m...

Embodiment 2

[0137] Such as figure 2 As shown in the route b, the method of Example 2 is with reference to Example 1, the difference is that: the sebacic acid mother liquor layering step is adopted, all the first wastewater and part of the third wastewater are recycled, and neutralization and extraction are used. And total evaporation process the second waste water to obtain the 3rd waste water, specifically as follows:

[0138] Sebacic acid mother liquor stratification ratio: upper layer 50%, lower layer 50%.

[0139] Recycling of the first waste water: recycle 100% of the first waste water to replace part of the added water before the neutralization step;

[0140] Recycling of the third waste water: recycle 60% of the third waste water to replace part of the added water before the neutralization step and the flushing water in the centrifugal filtration step;

[0141] (Note: the above ratios are weight ratios)

[0142] Sodium sulfate Sebacic acid Phenol Glycerin, fatty...

Embodiment 3

[0153] The method of embodiment 3 is with reference to embodiment 2, and difference is: combine with the refining method of sebacic acid. See the process image 3 .

[0154] details as follows:

[0155] Sebacic acid mother liquor stratification ratio: upper layer 50%, lower layer 50%.

[0156] Recycling of the first waste water: recycle 100% of the first waste water to replace part of the added water before the neutralization step;

[0157] Recycling of the third waste water: recycle 60% of the third waste water to replace part of the added water before the neutralization step and the flushing water in the centrifugal filtration step;

[0158] The refining method of sebacic acid is as follows: the semi-finished product of common sebacic acid is distilled, and the distillation includes the step of removing impurities by forward distillation at 195-210 °C and vacuum degree of 2500-5500 Pa, and at 180-200 °C , the sebacic acid distillation step carried out under a vacuum of 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com