Automatic steel rotation method for medium plates

An automatic and steel-turning technology, applied in image data processing, instruments, workpiece manipulation, etc., can solve problems affecting the stable production process of high-grade products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The detailed control process of a method for automatic steel transfer of medium and thick plates of the present invention will be described in conjunction with an embodiment.

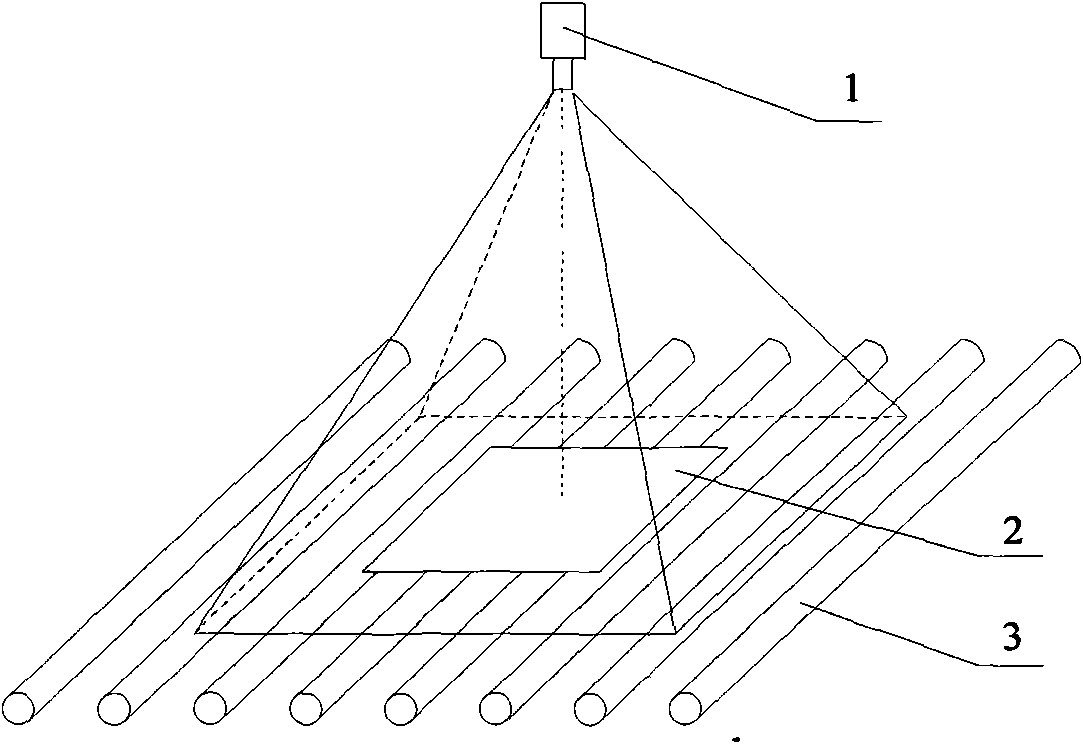

[0078] The required device of the present invention comprises video camera, camera lens, video signal photoelectric conversion module and 1394 image acquisition card and industrial PC, image data is converted by video signal photoelectric conversion module, is transmitted by multi-mode optical cable, camera selects black and white area array digital camera for use, The lens is M1614-MP with a focal length of 16mm and M2514-MP with a focal length of 25mm. The image acquisition card is a high-speed digital image acquisition card. The industrial PC is IPC-610H. The installation method of the camera is as follows: figure 1 shown.

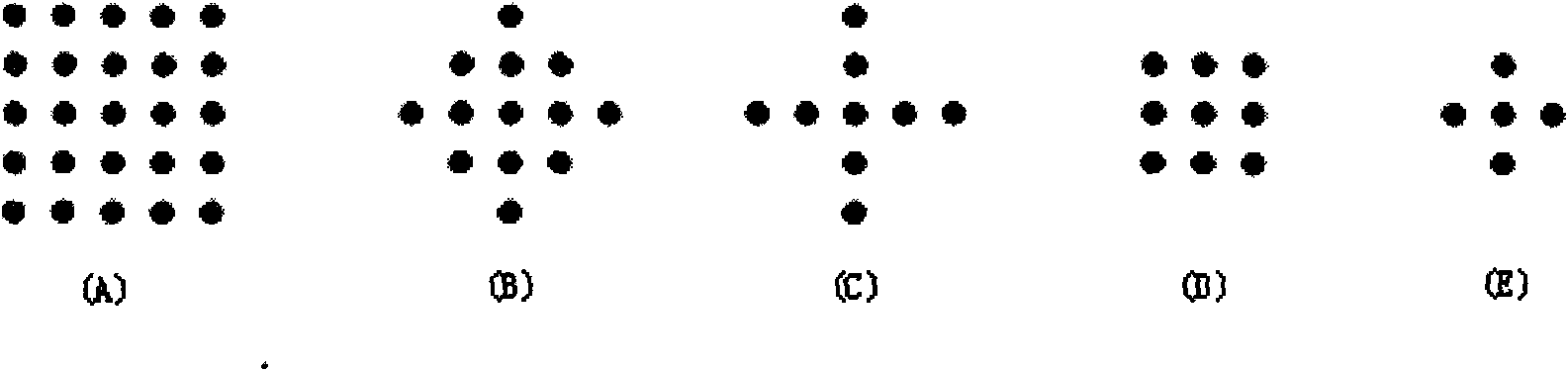

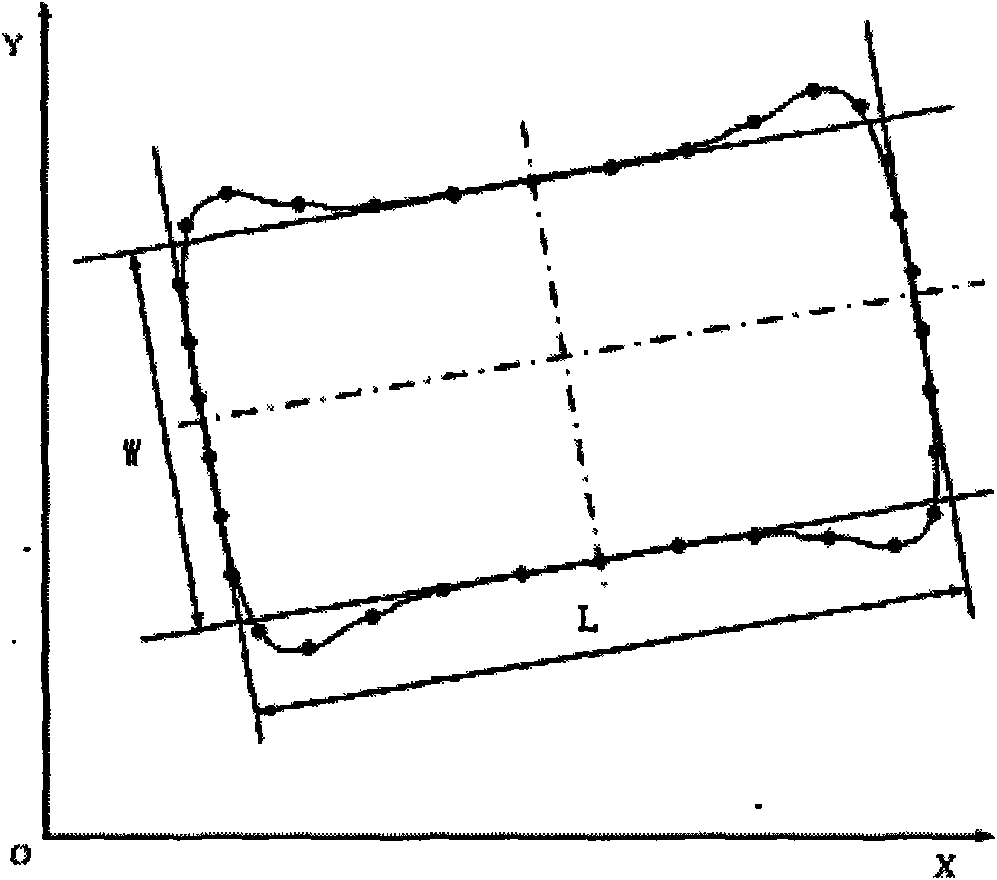

[0079] A kind of machine vision-based automatic steel transfer method for medium and thick plates of the present invention, the control steps are as follows: Figure 4 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com