Flue gas desulfurization process through calc-alkaline regeneration magnesium sulfite cycle absorption method

A magnesium sulfite and desulfurization process technology, applied in the field of flue gas desulfurization process, can solve the problems of high power consumption and operating cost, high power consumption, high requirements for anti-corrosion, wear resistance and anti-blocking, and achieve the effect of improving the absorption reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

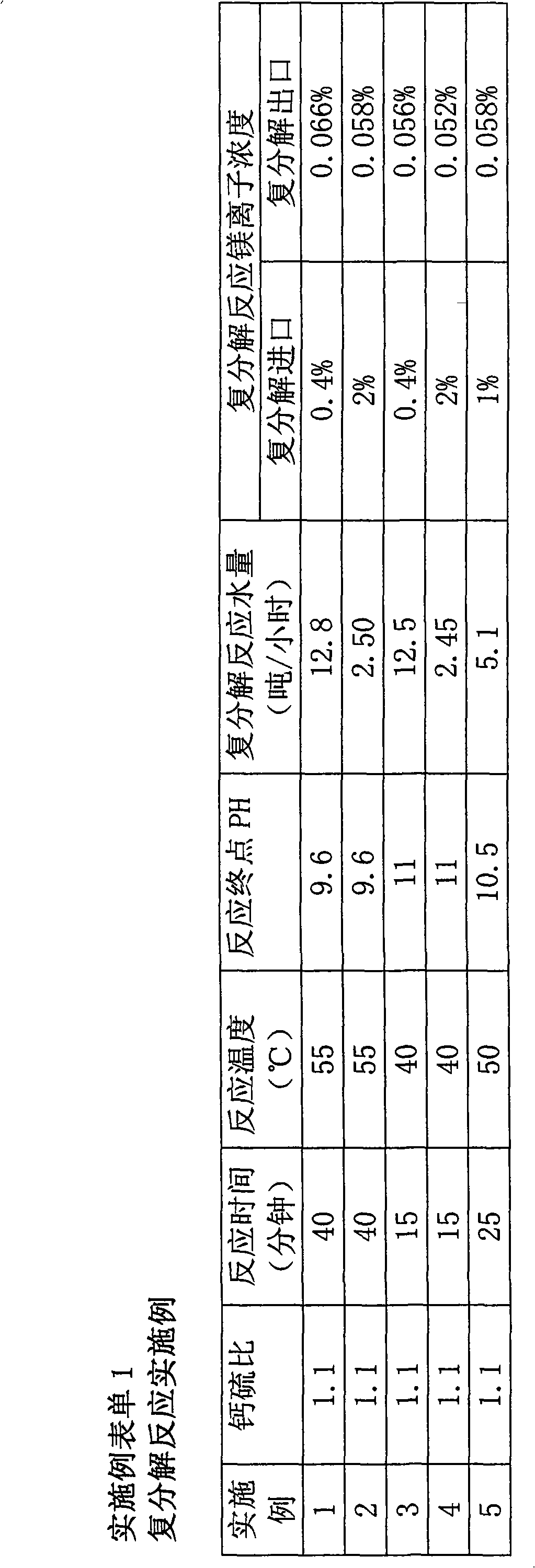

Examples

Embodiment

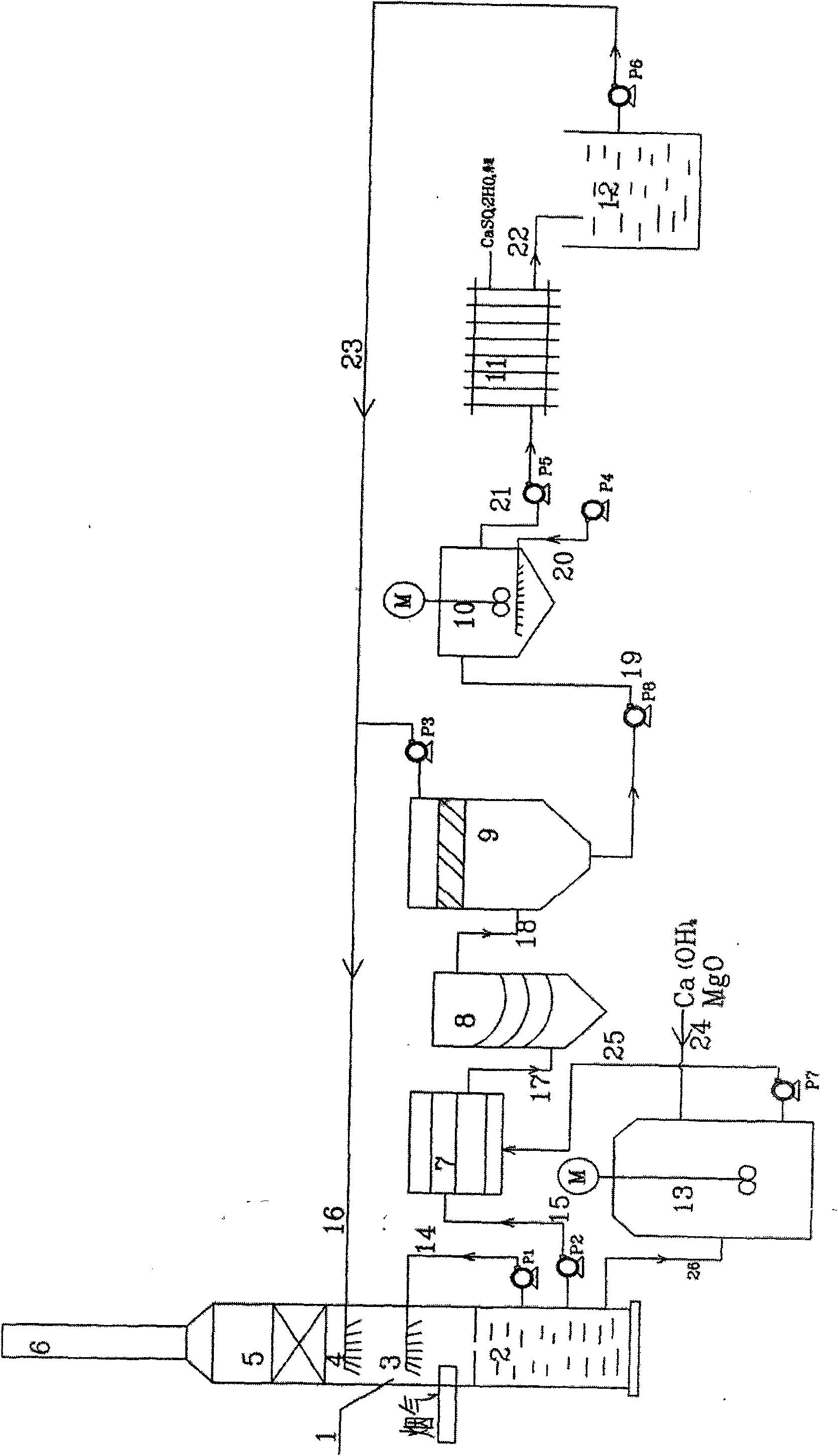

[0051] Such as process flow chart figure 1 Shown: The sulfur-containing flue gas that has been dust-removed enters the desulfurization absorption tower 1 from the flue in front of the tower, and is countercurrently contacted with the absorption liquid sprayed from the lower spray 3 and the upper spray 4 to absorb desulfurization, and is demisted by the demister 5 After that, it is emptied through the chimney 6. Part of the absorption liquid in the liquid storage section 2 at the bottom of the tower is pumped by the circulating spray pump P1 through the pipeline 14 into the lower spray 3 in the absorption tower to continue desulfurization and absorption. 24 The input calcium hydroxide undergoes metathesis reaction, and the metathesis reaction product enters the static mixer through the pipeline 25 from the slurry pump P7, and another part of the absorption liquid from the liquid storage section 2 at the bottom of the tower is pumped into the static mixer through the pipeline 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com