Adsorbent for selectively removing low-concentration sulfur dioxide from gas containing carbon dioxide

A carbon dioxide and sulfur dioxide technology, applied in the direction of absorption, reagents, inorganic chemistry, etc., can solve the problems of high energy consumption and secondary pollution, and achieve the effect of small circulation, no secondary pollution, and saving power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

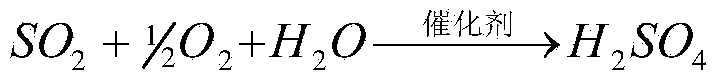

Method used

Image

Examples

Embodiment 1

[0031] Step 1. Add 0.2461g of sodium acetate, 0.2g of manganese sulfate and 0.005g of sodium dodecylbenzenesulfonate into 60g of water as the initial absorption solution. 2 2000ppm CO 2 Gas and air are absorbed, and the pH value of the absorption liquid and the outlet SO are detected every ten minutes 2 Concentration changes, the outlet concentration is below 50ppm within 70 minutes of absorption, and the absorption rate is as high as 99%. After 160 minutes of absorption, the absorption is saturated, and the pH value of the absorption solution is 3.48. stop ping SO 2 and CO 2 mixed composition. Stop the gas flow, and detect the sulfate content in the absorption solution.

[0032] Step 2. Continue to add 0.2461g of sodium acetate solid at a temperature of 40°C, pass air into it for forced oxidation for 120 minutes, and detect SO by spectrophotometry. 4 2- content.

[0033] Step 3. Add 0.2g CaCO to the absorption solution after forced oxidation 3 , stir well, and filter...

Embodiment 2

[0035] Step 1. Add 0.2889g sodium propionate, 0.2g manganese sulfate and 0.005g sodium dodecylbenzenesulfonate to 60g water as the initial absorption liquid, and at a temperature of 40°C, pass through 2 2000ppm CO 2 Gas and air are absorbed, and the pH value of the absorption liquid and the outlet SO are detected every ten minutes 2 Concentration changes, the outlet concentration is below 100ppm within 70 minutes of absorption, and the absorption rate is as high as 96%. After 180 minutes of absorption, the absorption is saturated, and the pH value of the absorption solution is 3.56. Stop the gas flow, and detect the sulfate content in the absorption solution.

[0036] Step 2 and step 3 are the same as in Example 1, and the amount of sodium propionate added is 0.2889g.

Embodiment 3

[0038] Step 1. Add 0.46g sodium succinate, 0.2g manganese sulfate and 0.005g sodium dodecylbenzenesulfonate to 60g water as the initial absorption liquid, and at a temperature of 40°C, pass through 2 2000ppm CO 2The gas is absorbed, and the pH value of the absorption liquid and the outlet SO are detected every ten minutes 2 Concentration changes, the outlet concentration is below 90ppm within 40 minutes of absorption, and the absorption rate is as high as 99%. After 150 minutes of absorption, the absorption is saturated, and the pH value of the absorption solution is 3.78. Stop the gas flow, and detect the sulfate content in the absorption solution.

[0039] Step 2 and step 3 are the same as in Example 1, and the amount of sodium succinate added is 0.46g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com