Dust-filtering air processor and

An air processor and dust filter technology, applied in the field of air treatment equipment, can solve the problems of low moisture content in exhaust air, difficult filtration of spray dust removal water, affecting the working environment, etc., to reduce usage, high water removal efficiency, and noise reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

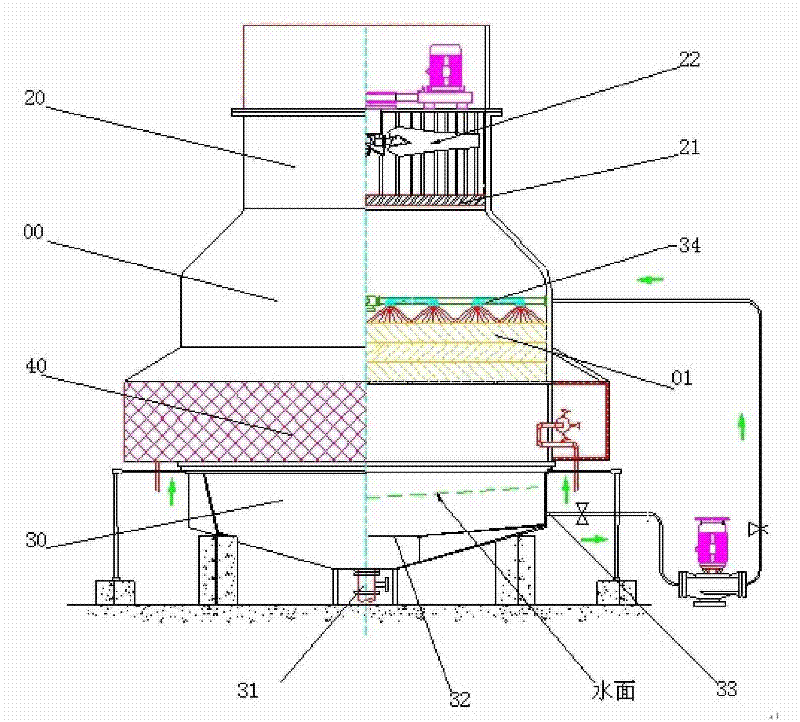

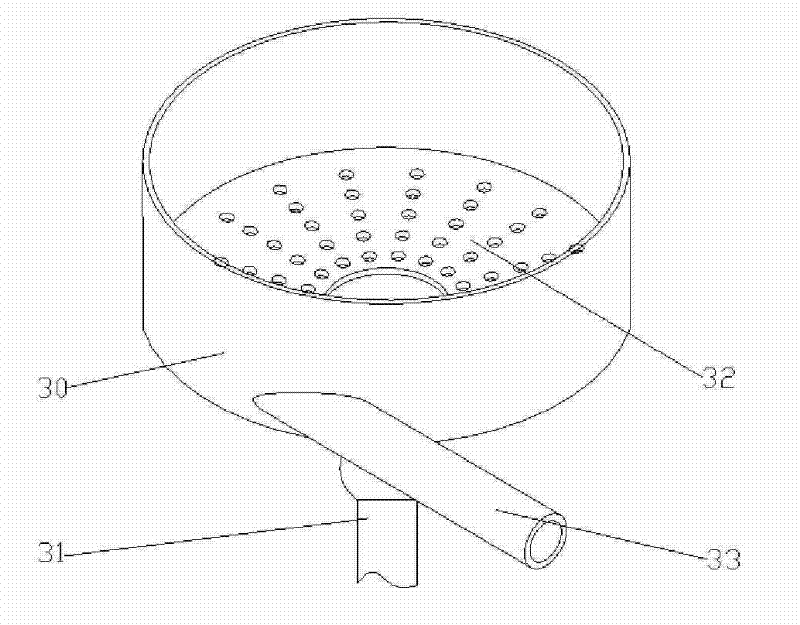

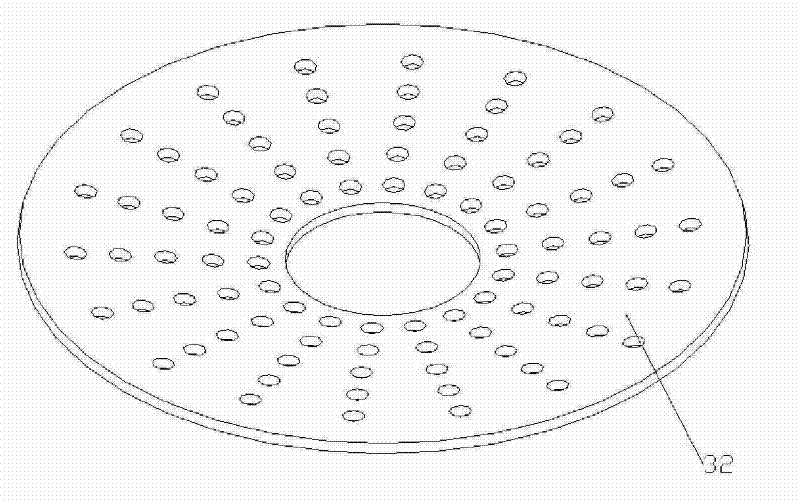

[0024] Example: According to figure 1 As shown, a dust filter air handler is composed of a water collection basin 30, an air inlet 40, a cylindrical tower body 00, a packing material 01, a spray system 34, a small cylinder body 20, a water eliminator 21 and a fan 22. The shape of the water collection basin 30 is a funnel structure, the water outlet 33 is opened in the tangential direction of the outer wall of the circle, the dust removal plate 32 is below the water outlet 33, and the dust removal plate 32 is a conical plate with a hole in the middle, and the inner density is distributed on the conical plate. Outer sparse small holes, a conical settling chamber is arranged below the dust removal plate 32, and a sewage discharge pipe 31 is arranged at the bottom of the settling chamber (see figure 2 , 3 ); the air inlet 40 is a U-shaped mesh plate surrounded by a diameter greater than the cylindrical tower body 00; the packing 01 is a honeycomb panel with 3 layers of staggered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com