Edible aerated oil-and-water emulsion

A water emulsion, emulsion technology, applied in the direction of edible oil/fat, edible oil/fat phase, food forming, etc., can solve the problem that additives are not allowed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Aerated three emulsions were made according to the following recipes:

[0060] Composition (weight%)

A

B

C

undenatured egg yolk protein #

1.2

-

-

egg yolk protein #

-

1.2

-

egg yolk protein #

-

1.2

Oil

60

60

60

NaCl aqueous solution (0.75M)

margin

margin

margin

total

100

100

100

[0061] # The indicated concentrations refer to egg yolk proteins.

[0062] Yolk granules and yolk slurry were separated from the same undenatured hen's egg yolk used in the preparation of one of the mayonnaise products. Egg yolks are obtained by the following process:

[0063] · Break fresh eggs

[0064] Roll the yolks on tissue until all the whites are removed

[0065] Use a glass pipette to break through the yolk membrane to release the yolk from the "coating"

[0066] · Collect the released egg yo...

Embodiment 2

[0072]Example 1 was repeated, except this time the pH of the aqueous phase was lowered to pH 4.0 by the addition of aqueous acetic acid / sodium acetate buffer (50 mM). The emulsion was homogenized and aerated using similar homogenization conditions as in Example 1.

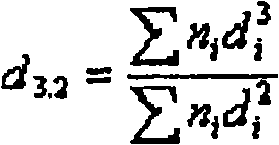

[0073] This time the following results are obtained:

[0074] A

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com