Chemoluminescent substrate

A technology of chemiluminescence and substrate solution, which is applied in the field of immunoassay, can solve the problems of low sensitivity and limited effect of enhancing luminescence, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare luminescent agent solution and oxidizing agent solution of 1000mL chemiluminescence substrate solution, the specific formula is as follows.

[0033] Chemiluminescent substrate solution Luminescent agent solution:

[0034] Luminol 10mmol / L

[0035] 4-Hydroxybiphenyl 0.3mmol / L

[0036] 4-iodophenylboronic acid 0.05mmol / L

[0037] 0.2mol / L boric acid-borax buffer pH 8.7

[0038] Chemiluminescence substrate solution oxidant solution:

[0039] Carbamide peroxide 3.5mmol / L

[0040] Tween 20 0.1% (volume)

[0041] 0.2mol / L phosphate buffer pH7.2

[0042] The preparation of 1000mL luminescent agent solution of chemiluminescence substrate can adopt the following method: take 1.7716g of luminol, 0.051g of 4-hydroxybiphenyl, 0.012g of 4-iodophenylboronic acid, 11.4g of boric acid, 4.9g of borax, and use bis Dissolve in distilled water to 1000mL, pH 8.7.

[0043] The preparation of 1000mL oxidant solution of chemiluminescent substrate solution can adopt the followin...

Embodiment 2

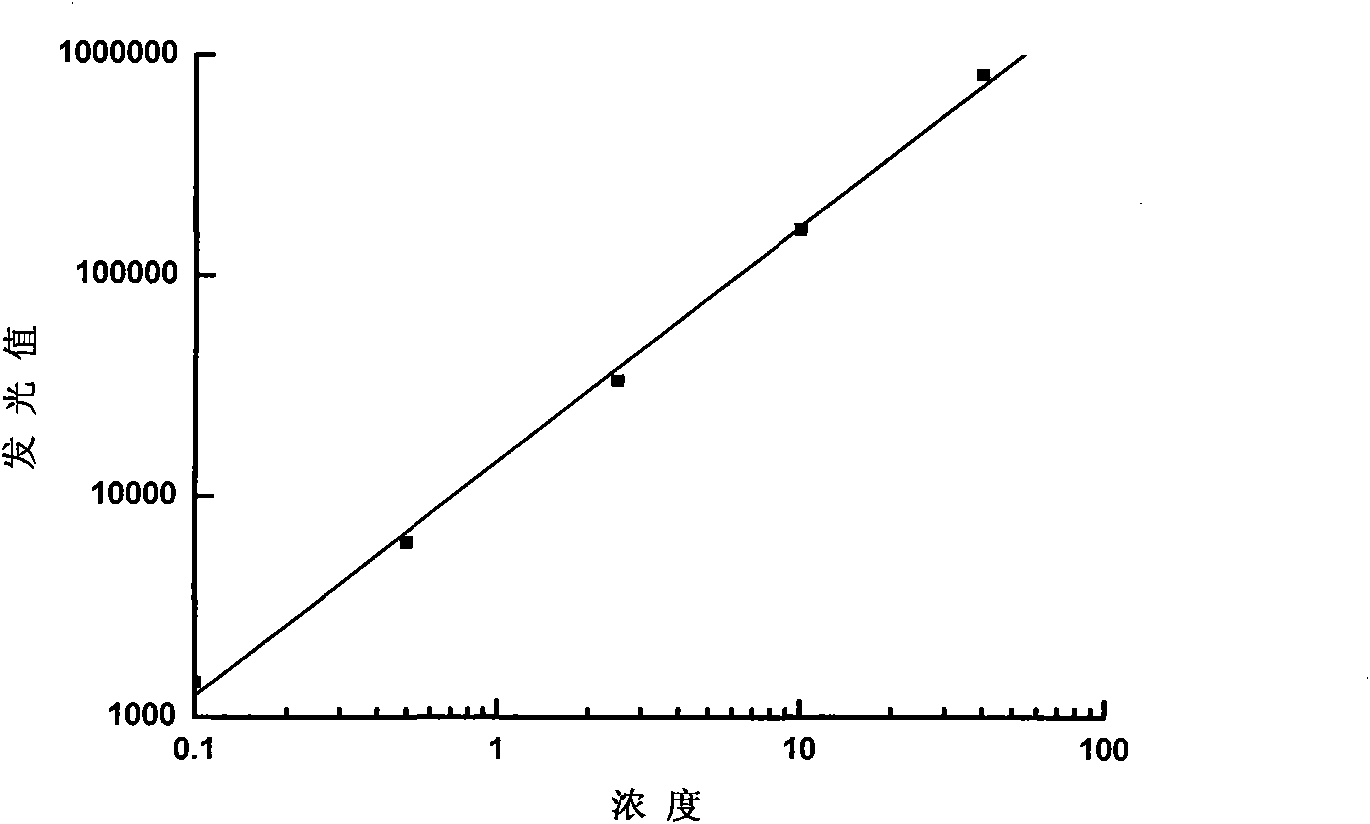

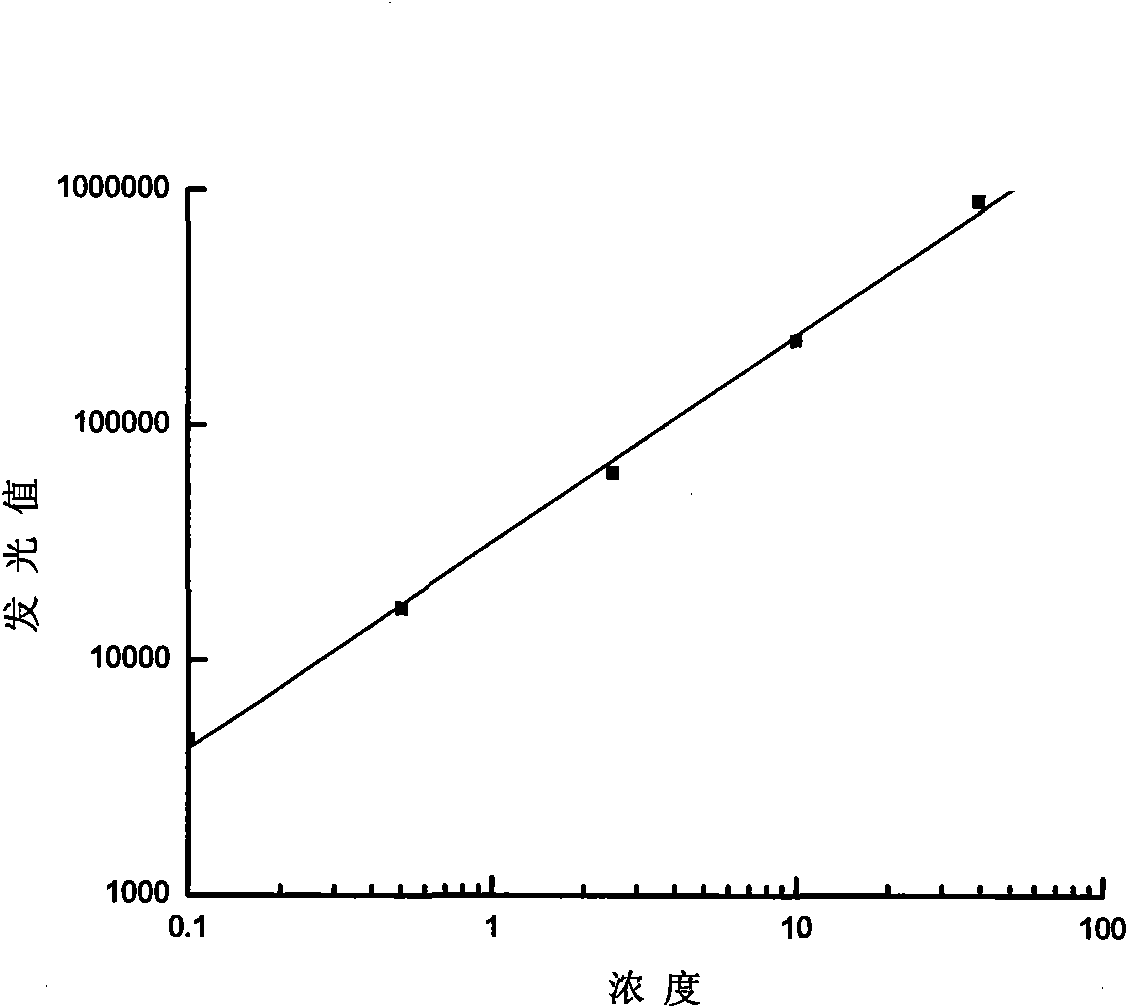

[0045] Compare the luminescent intensity of the luminescent substrate solution described in the above-mentioned Example 1 with the signal Reagent A and signal Reagent B luminescent substrate solutions imported from the United States monobind company in the assay for the determination of thyroid stimulating hormone (TSH).

[0046] Experimental procedure: add 50 μL of sample, calibrator and enzyme marker to a microwell plate, react at room temperature for 45 minutes, wash 5 times with washing solution, then dry it on absorbent paper, add the mixed luminescent substrate to each well After 100 μL of the substance solution was protected from light at room temperature for 5 minutes, the relative luminescence value (RLU) of each well was detected with a chemiluminescence instrument.

[0047] The commercially available signal Reagent A and signal Reagent B luminescent substrate solutions produced by the monobind company in the United States and the luminescent substrate solution in Exa...

Embodiment 3

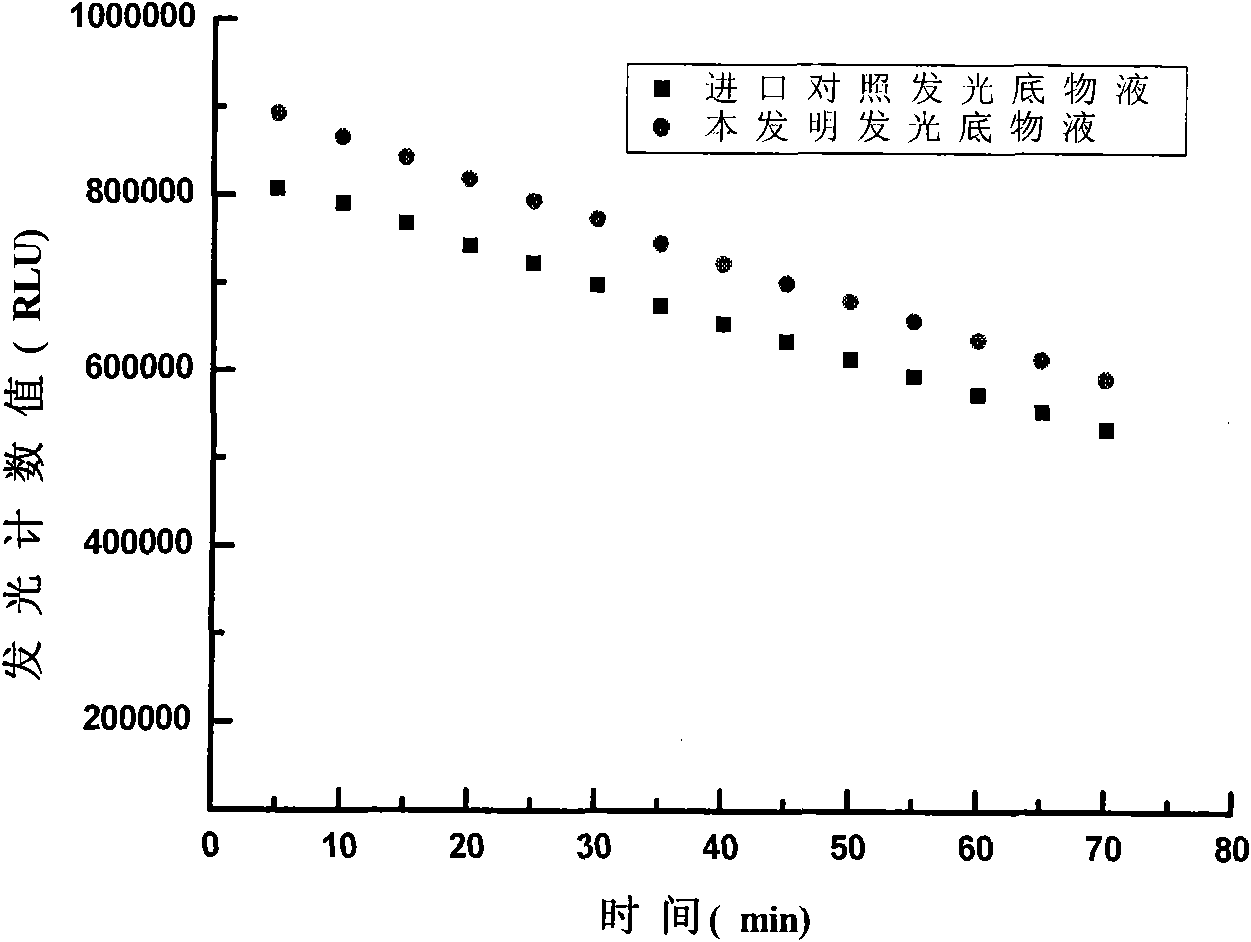

[0068] Compare the luminescent substrate solution described in the above-mentioned Example 1 with the commercially available signal Reagent A and signal Reagent B luminescent substrate solutions (imported control luminescent substrate solution) produced by the U.S. monobind company to measure the thyroid-stimulating hormone (TSH) in the experiment. Luminous plateau.

[0069] Add 50 μL of each sample and enzyme marker to a microwell plate, react at room temperature for 45 minutes, wash 5 times with washing solution, then dry it on absorbent paper, and add 100 μL of mixed luminescent substrate solution to each well. After adding the luminescent substrate solution, measure it with a luminometer every 5 minutes for 70 minutes, and count the changes in the luminescence value of the same sample within 70 minutes.

[0070] The imported luminescent substrate solution and the luminescent substrate solution described in Example 1 were used for experiments respectively.

[0071] The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com