Special centrifugal pump with air-cooled type bearing body

A centrifugal pump, a special technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problem of low working efficiency of special centrifugal pumps in bearing boxes, and achieve the effect of reducing energy consumption and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

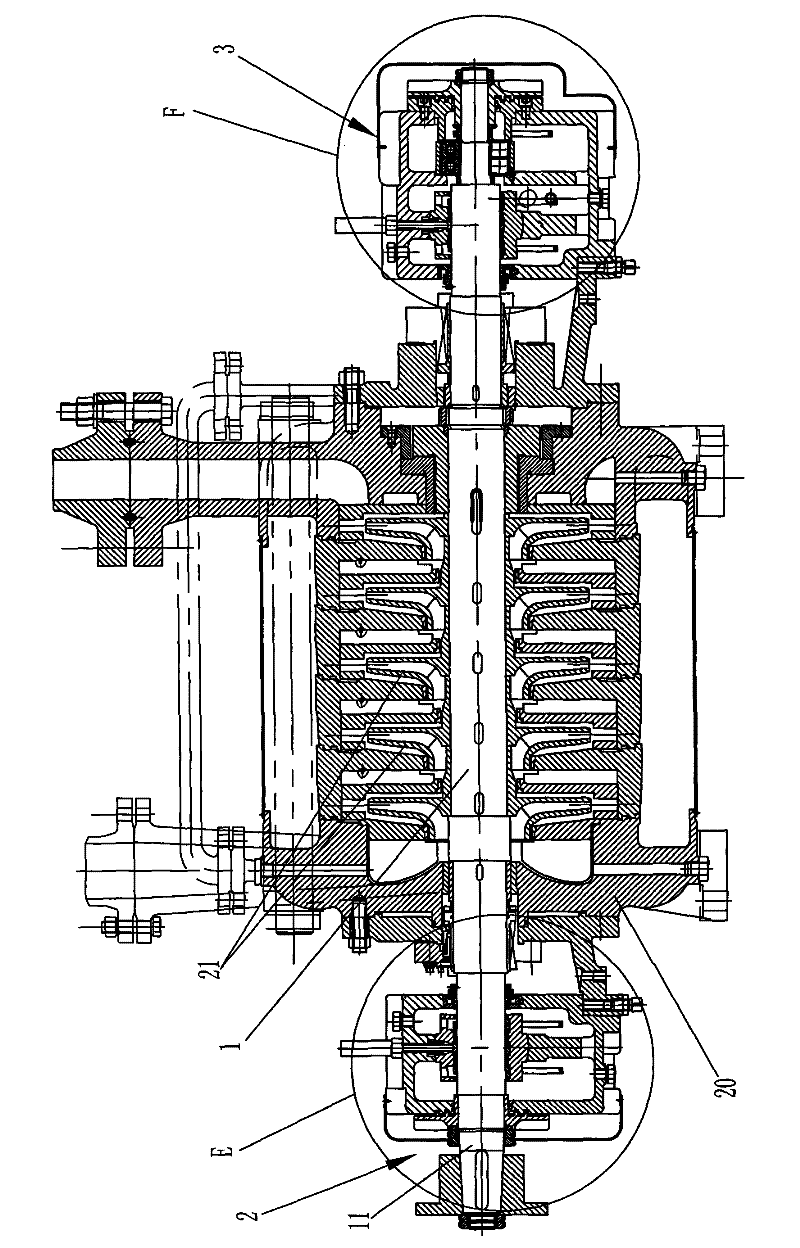

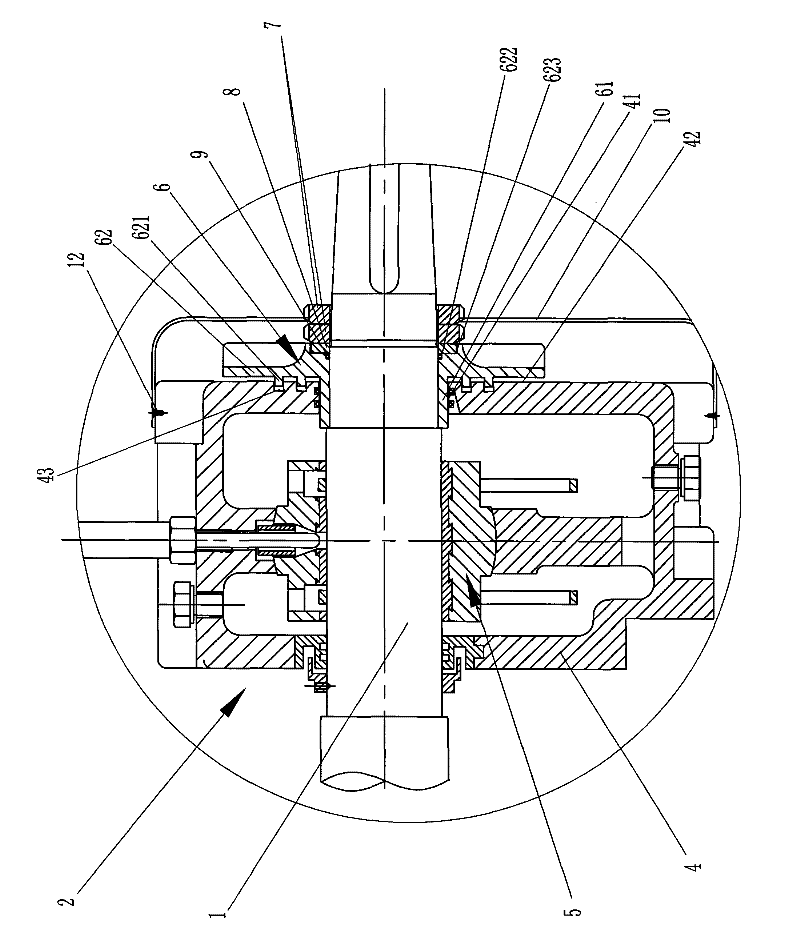

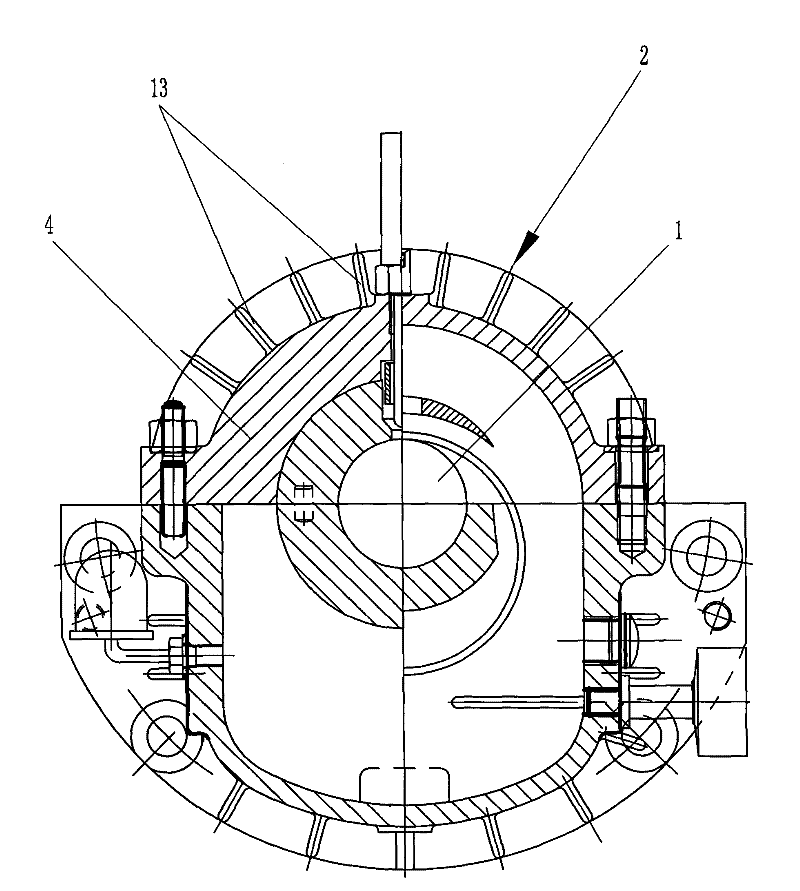

[0014] Such as figure 1 As shown, the specific embodiment of the present invention is an air-cooled bearing box special centrifugal pump, including a pump body 20, an impeller 21, a main shaft 1, front and rear bearing boxes 2, 3, and an air-cooling mechanism, and the main shaft 1 is horizontally arranged on Inside the pump body 20, multi-stage impellers 21 are fixed on the main shaft 1 with keys one by one. Such as figure 2 , 3 , 4, and 5, the front and rear bearing housings 2 and 3 all include components such as the casing 4, the end cover and the bearing assembly 5, and the front and rear bearing housings 2 and 3 are placed at the two ends of the main shaft 1 respectively, and the main shaft 1 wears Through the main shaft hole 41 on the case body 4 of the bearing box and the non-driving end of the main shaft is exposed from the case body 4, the bearing assembly 5 is placed in the case body 1 and fixed on the main shaft 1, and the air cooling mechanism adopts a dust-proof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com