Cooling shaft piston

A technology for cooling shafts and pistons, which is applied to liquid variable displacement machines, variable displacement pump components, machines/engines, etc., and can solve the problems of reducing the working efficiency of pistons, increasing the amount of coolant, and low cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

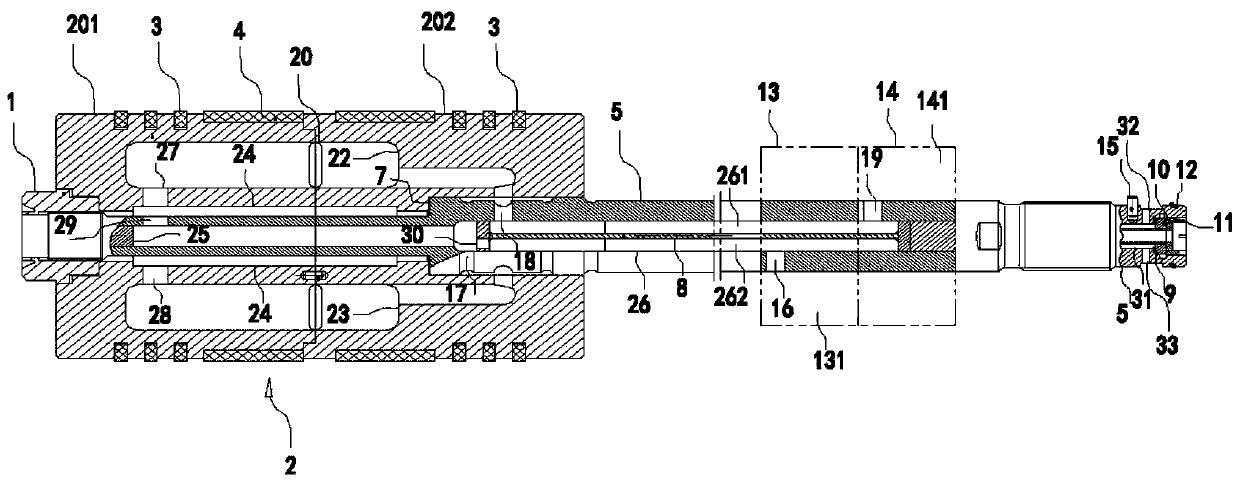

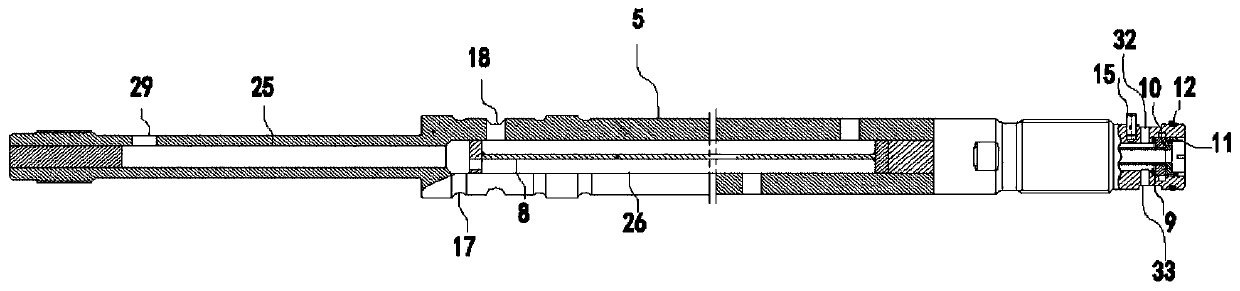

[0023] Such as figure 1 and figure 2 As shown, the cooling shaft piston includes a piston body 2, a piston rod body 5, a first sealed double compartment 13 and a second sealed double compartment 14;

[0024] The piston body 2 includes a front half piston body 201 and a rear half piston body 202; the ends of the front half piston body 201 and the rear half piston body 202 are fixedly connected horizontally; inside the piston body 2, they are respectively symmetrical up and down An upper piston body cavity 22 and a lower piston body cavity 23 are provided; a piston rod body assembly channel 24 is arranged laterally in the middle region of the piston body 2; The front end of 201 is fixedly connected;

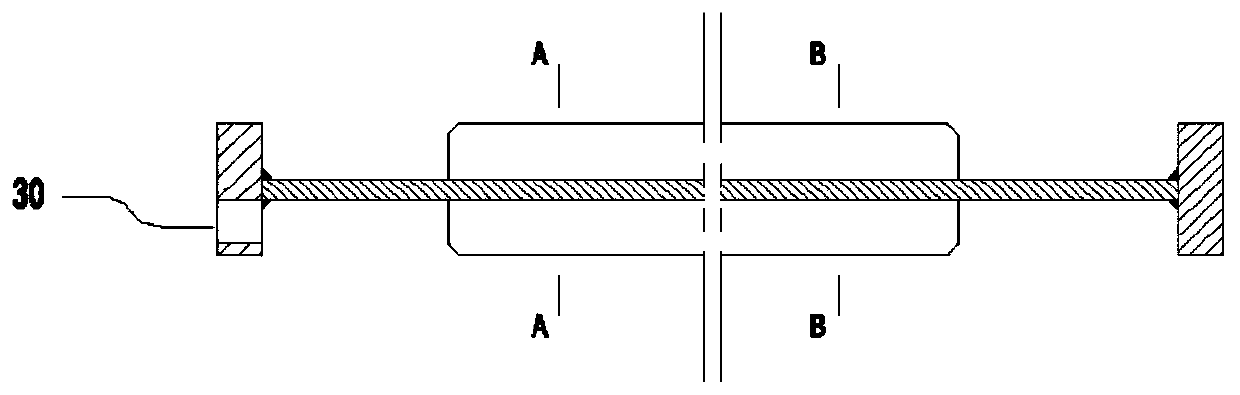

[0025] The inside of the piston rod body 5 is horizontally provided with a rod body front end cavity 25 and a rod body rear end cavity 26 in turn; a piston rod core 8 is horizontally fixed in the rod body rear end cavity 26 to form upper and rear ends independent of each other. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com