Internal-bonded water-proof technique for externally-bonded waterstop

A technology of waterstop and technology, which is applied in the field of waterproof technology for externally pasted waterstop and internally pasted, can solve the problems of difficult sealing between angle steel and concrete structures, difficult operation, and influence on use, and achieve strong adaptability to expansion and contraction deformation and improve tightness. Strengthen and seal effect, improve the effect of flexural tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

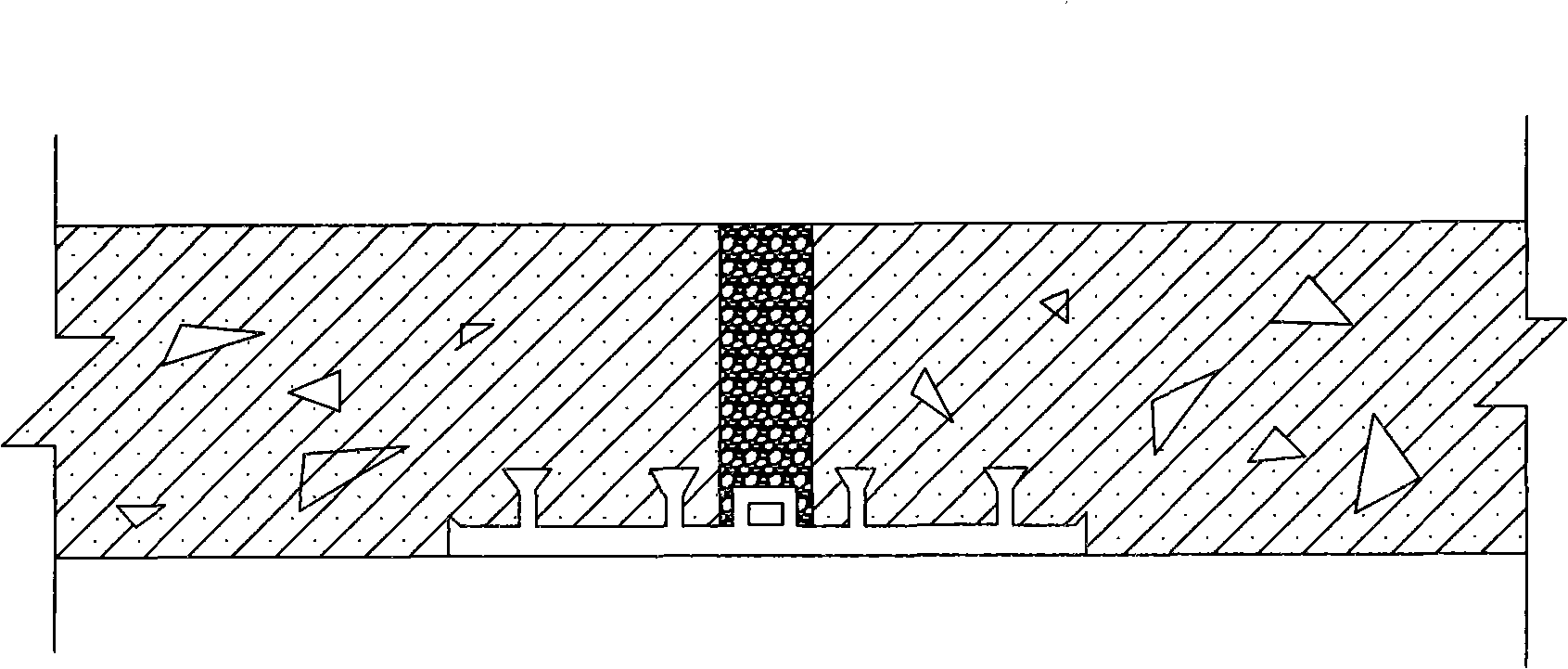

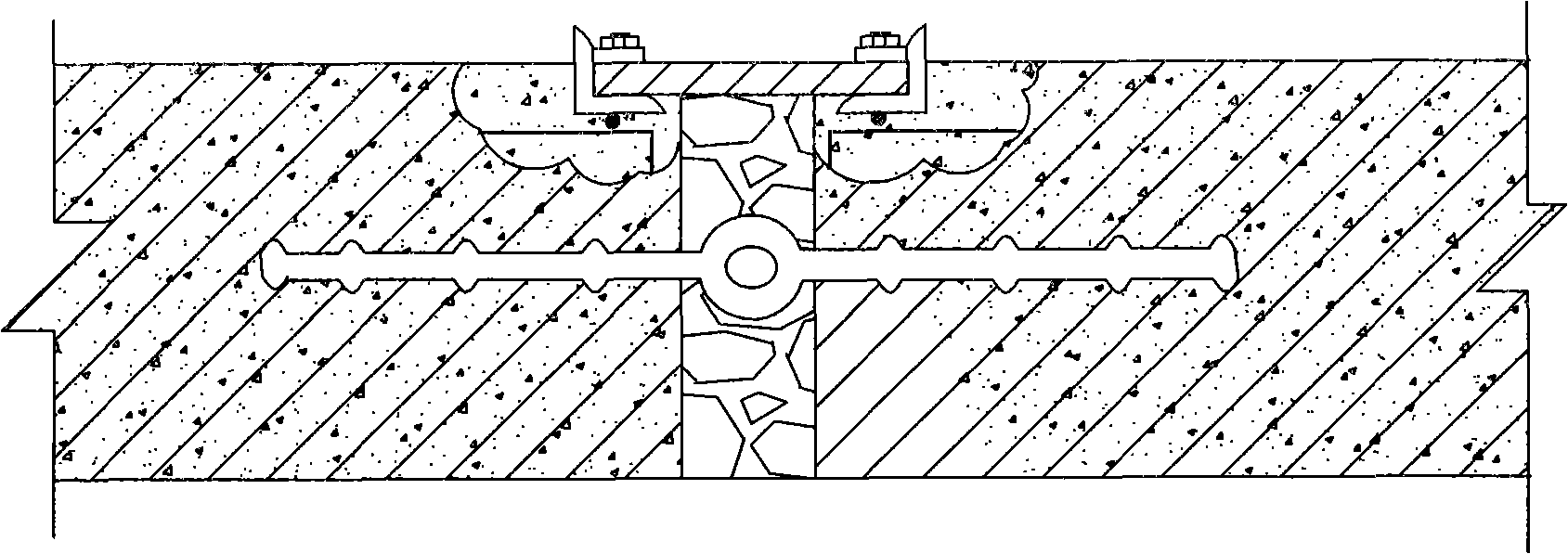

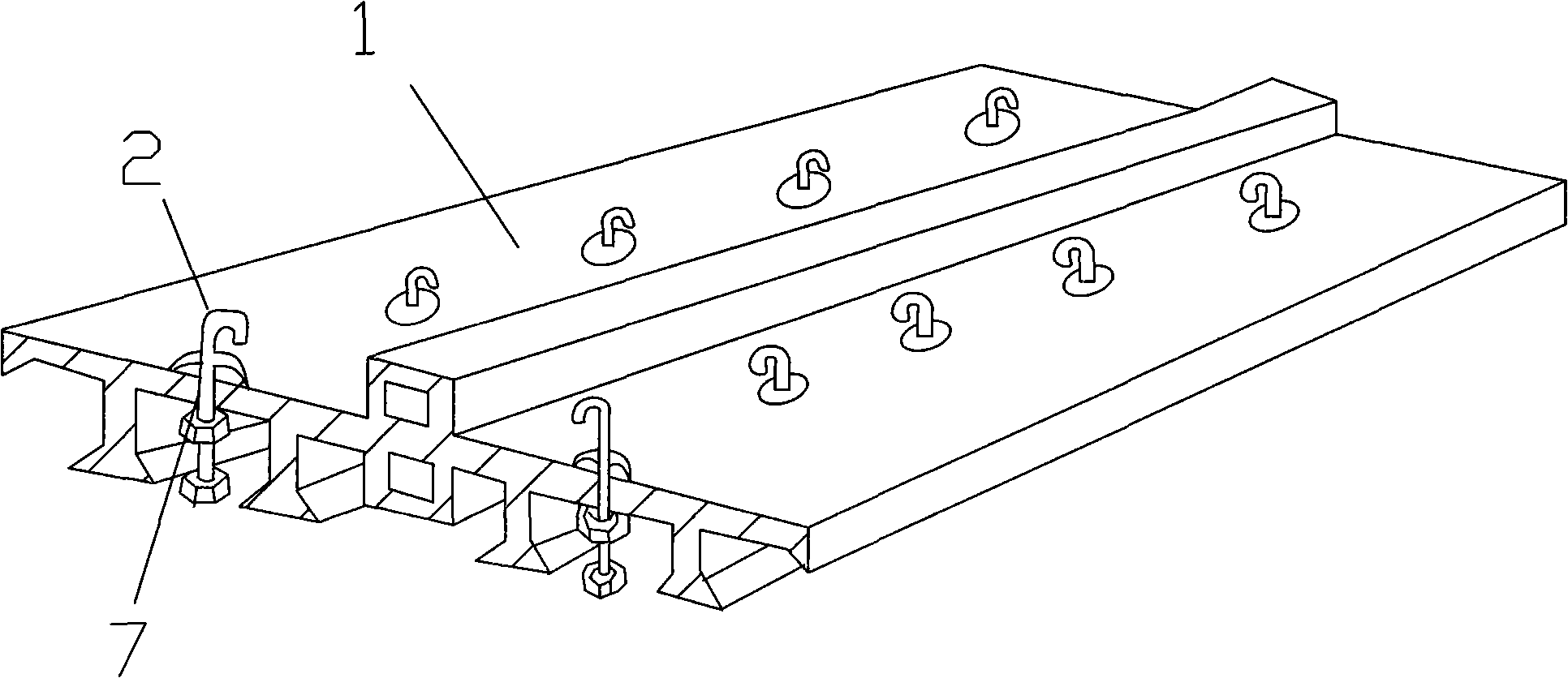

[0025] see image 3 , Figure 4 , a kind of water-stop waterproofing technology for external water-stop, which includes (1), preliminary plugging of the leaking seam produced by the damaged mid-buried water-stop 8, to block the water; (2) in the expansion joint 6 Both sides are located at the inner surface 11 of the concrete structure 10 and chisel grooves 5; (3), plant equal height or equal length anchor bars 4 at the bottom of the groove, put the external waterstop 1 into the groove, And make the top of the anchoring steel bar support and fix the externally attached waterstop, the waterstop includes the waterstop body 10, and the waterstop body is provided with 8 holes 7, and the two-way distance between the holes is 400mm The hole is provided with a pair of tie bars 2, and the two ends of the hole are provided with a convex ring 11; (4), a formwork 9 is arranged on the groove surface, and the two ends of the formwork are closely attached to the inner surface of the concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com