Device for improving advanced nitrogen and phosphorus removal by step feed and method

A technology of deep denitrification and staged water inflow, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Improve and increase sewage treatment costs and other issues, to achieve the effect of being conducive to recycling, saving energy consumption for aeration, and preventing eutrophication of water bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

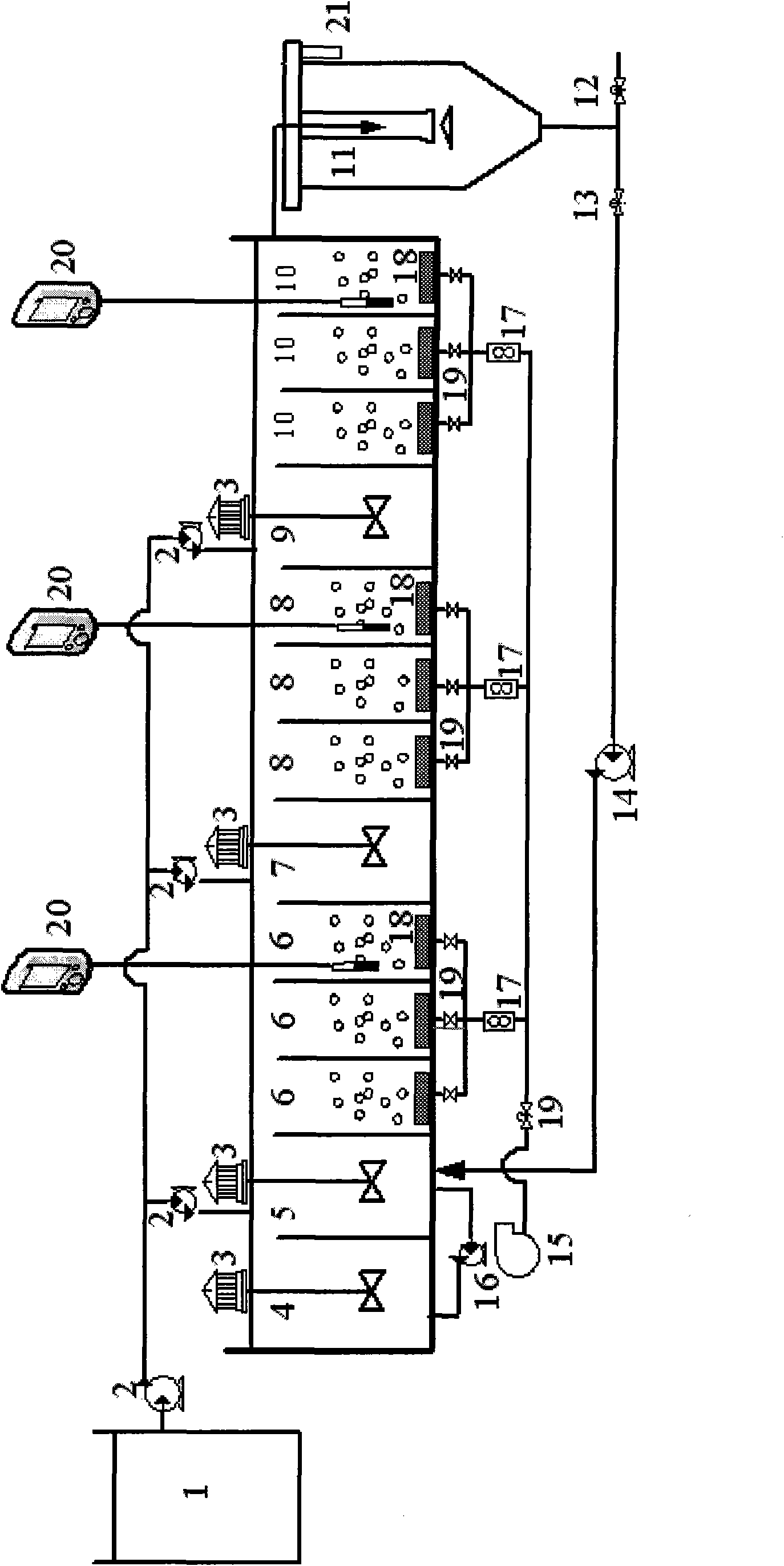

Method used

Image

Examples

example 1

[0039] Taking the actual domestic sewage in a family area of a university in Beijing as the treatment object (COD=180-265mg / L, TN=43.8-86.5mg / L, TP=4-8.4mg / L, C / N=2.08-6.05, C / P =21.4-66.3), the hydraulic retention time is 8h, the sludge age is 8-12d, the average sludge concentration is 3500±150mg / L, the sludge reflux ratio is 0.75, and the temperature is controlled by the heating rod at about 20°C. The test results show that the average COD The removal rate was 84.6%, and the average removal rates of TN and TP were 79% and 90%, respectively.

example 2

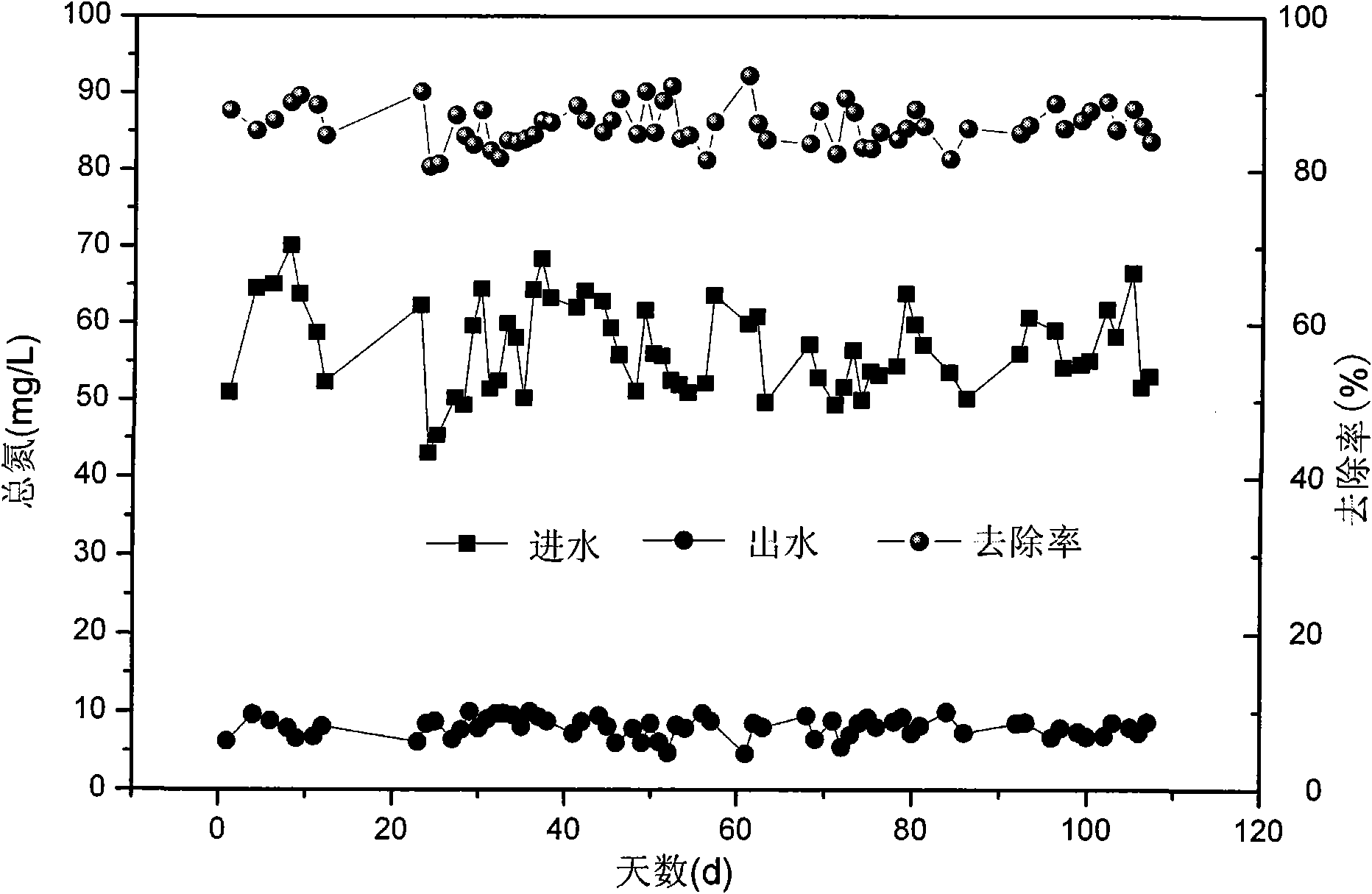

[0041] Taking the effluent from the primary sedimentation tank of a sewage treatment plant in Beijing as the treatment object (COD=119-565mg / L, TN=24.6-79.5mg / L, TP=0.48-13.3mg / L, C / N=1.5-6.4, C / N=1.5-6.4, C / P=35.7-74.5), hydraulic retention time 8-10h, sludge age 8-12d, average sludge concentration 5000±150mg / L, sludge reflux ratio 0.5-0.75, temperature controlled by heating rod at about 20°C, test The results showed that the average removal rate of COD was 87%, and the average removal rates of TN and TP were 82.5% and 95.02%, respectively. figure 2 , image 3 shown.

[0042] figure 2 In order to take the actual sewage as the treatment object, the system has been running continuously for more than 3 months to remove TN. The daily processing capacity of the pilot scale reactor is Q=1.02m 3 In the case of / d, the results of three consecutive months of operation show that although the influent TN fluctuates greatly, the effluent water quality is basically maintained below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com