System for casting and pouring propeller of ship

A pouring system and propeller technology, applied in the field of ship propeller casting pouring system, can solve the problems of shrinkage porosity, low yield of molten metal, oxidative slag inclusion in castings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

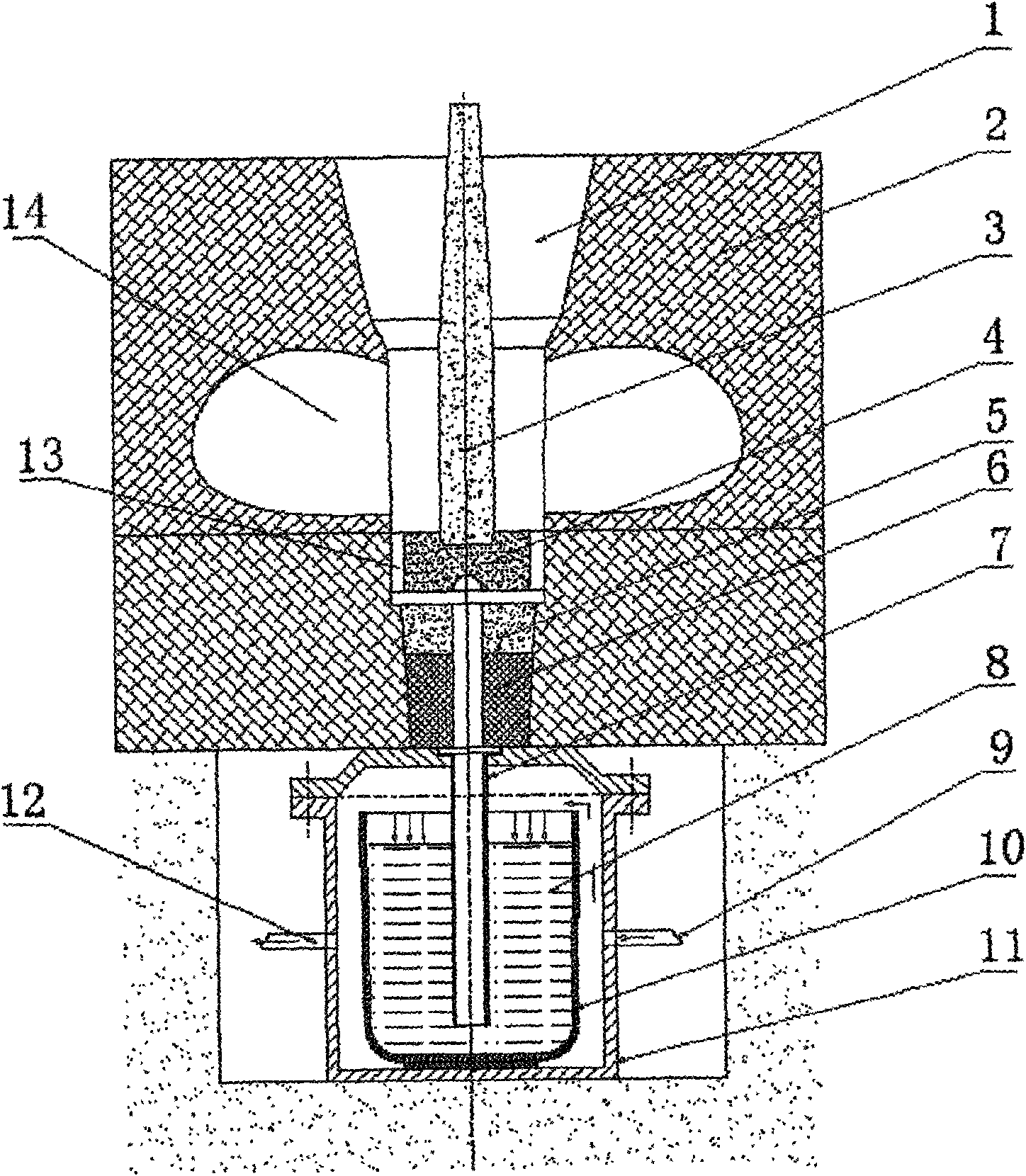

[0011] Such as figure 1 As shown, the ship propeller casting gating system includes a closed pressure tank 11, a ladle 10, a liquid riser 7, a gas injection mechanism, a graphite chilling sleeve 6, a core sand sleeve 5, a tile core box 4, a core 3 and The sand mold 2, the gas injection mechanism includes a compressed air inlet pipe 9 and a compressed air outlet pipe 12 connected to the same height in the middle of the closed pressure tank 11, the ladle 10 is placed in the closed pressure tank 11, and the liquid riser 7 is extended to accommodate high temperature. In the ladle 10 of the molten steel 8, a cavity 14 and a riser 1 on the upper part of the cavity 14 are formed between the sand mold 2 and the core 3 located at the center of the sand mold 2. Graphite quenching sleeve 6, core sand sleeve 5 and tile core box 3, core sand sleeve 5 is located above graphite chilling sleeve 6, graphite chilling sleeve 6 and core sand sleeve 5 have a riser pipe 7 through Through the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com