Large-current pulse LD laser driving power supply

A technology for driving power supply and laser, applied in lasers, generating electric pulses, laser parts, etc., can solve the problems of unstable output current pulse, low power, poor adaptability to load, etc., to achieve humanization, protection, and realization smart effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the drawings and specific embodiments.

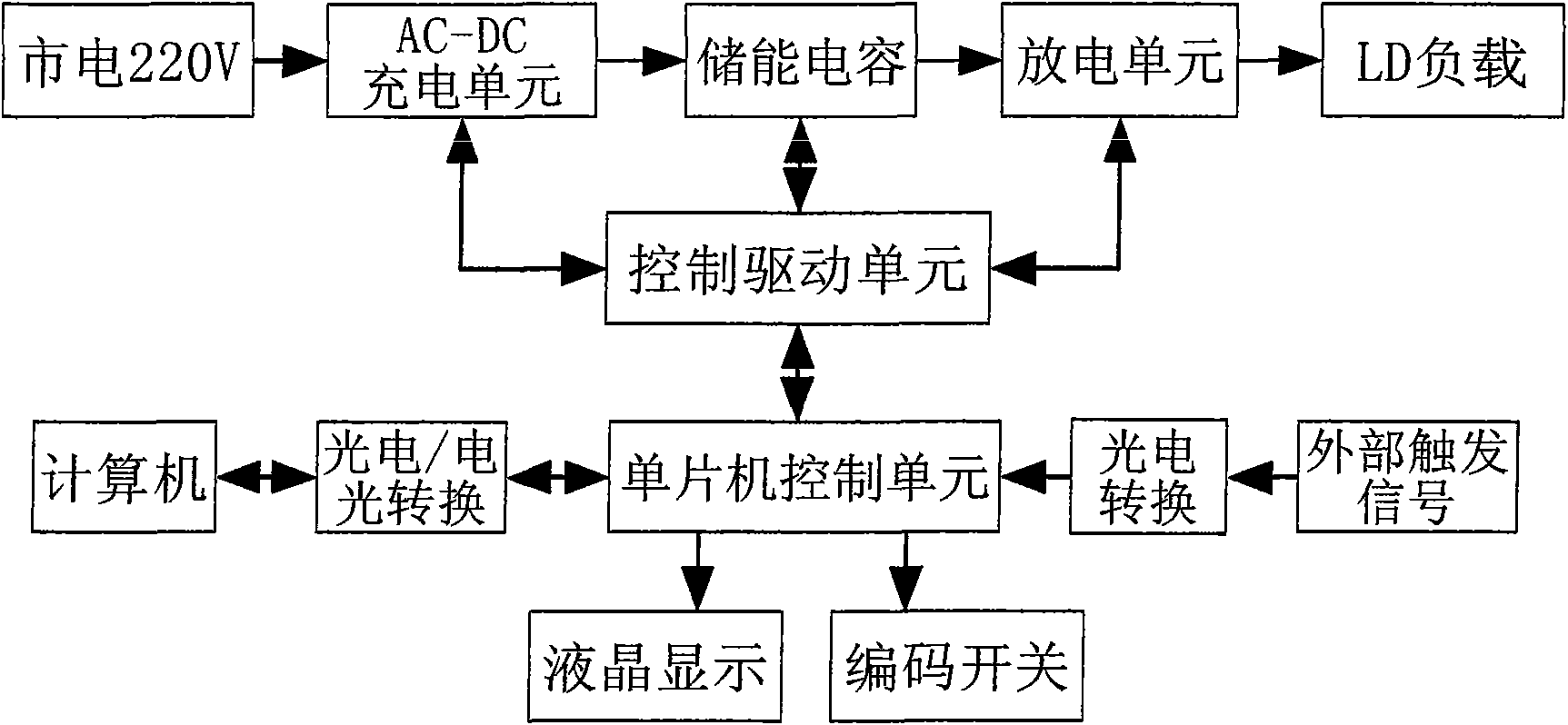

[0037] reference figure 1 The high-current pulsed LD laser drive power supply of the present invention includes an energy storage capacitor, an AC-DC charging unit, a discharge unit, a control drive unit, and a single-chip control unit; wherein the AC-DC charging unit connected to the external power supply is connected to the An energy storage capacitor, the energy storage capacitor is connected to the discharge unit, and the single-chip microcomputer control unit controls the energy storage capacitor, the AC-DC charging unit, and the discharge unit through the control drive unit. When the driving power supply of the present invention is working, the discharge unit is connected with the high-current pulsed LD laser to provide the laser with electric energy that meets the requirements.

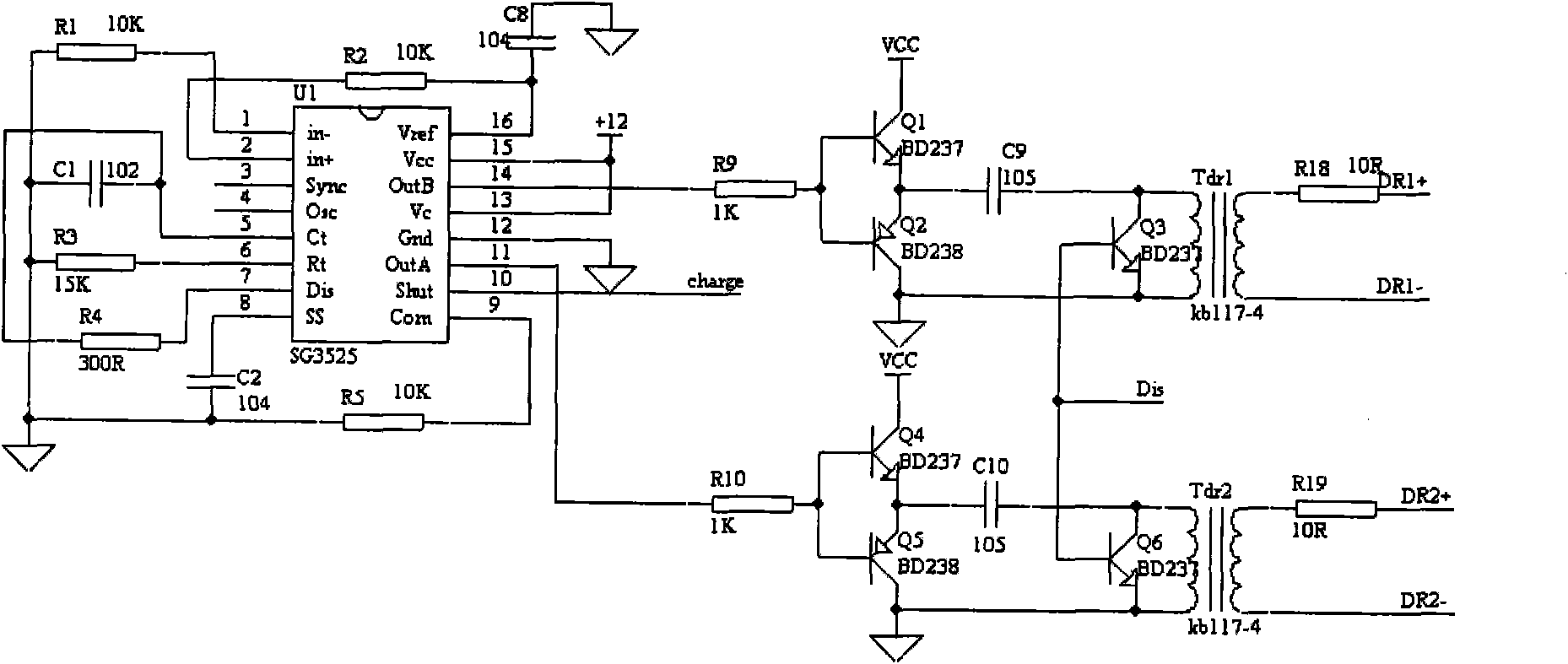

[0038] The specific functions of the above-mentioned units in the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com