Test result evaluation method of fault recorder

A fault recorder and evaluation method technology, applied in the direction of instruments, measuring devices, measuring electrical variables, etc., can solve the problem that there is no way to require manufacturers to do it, and achieve intuitive and clear scoring results, intuitive and clear conclusions, and accurate test conclusions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention is based on the test result evaluation method of the power system generating set and the line fault recorder. We take the type selection test of a power grid line fault recorder in a certain province as an example to specifically describe the application of the present invention.

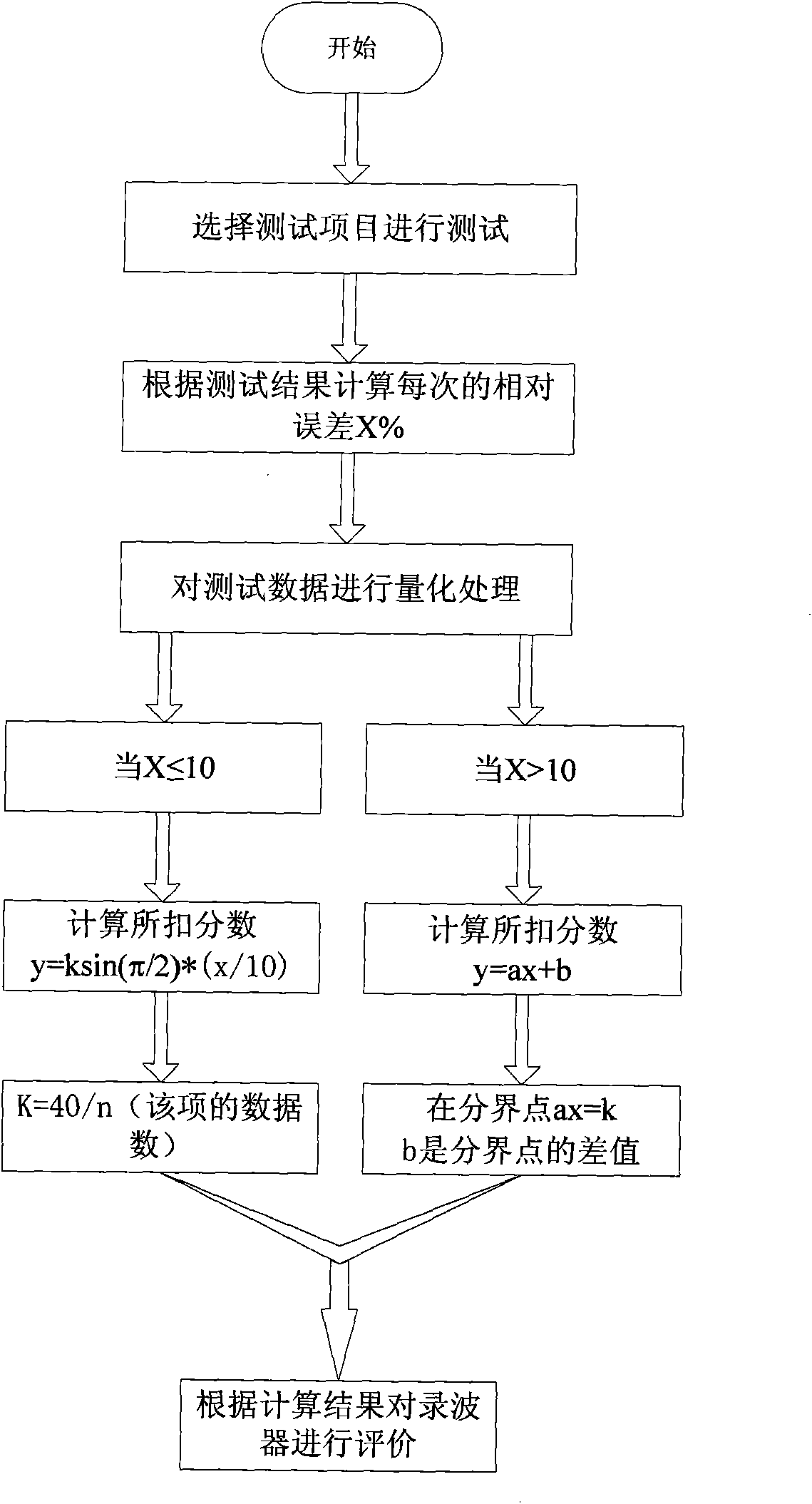

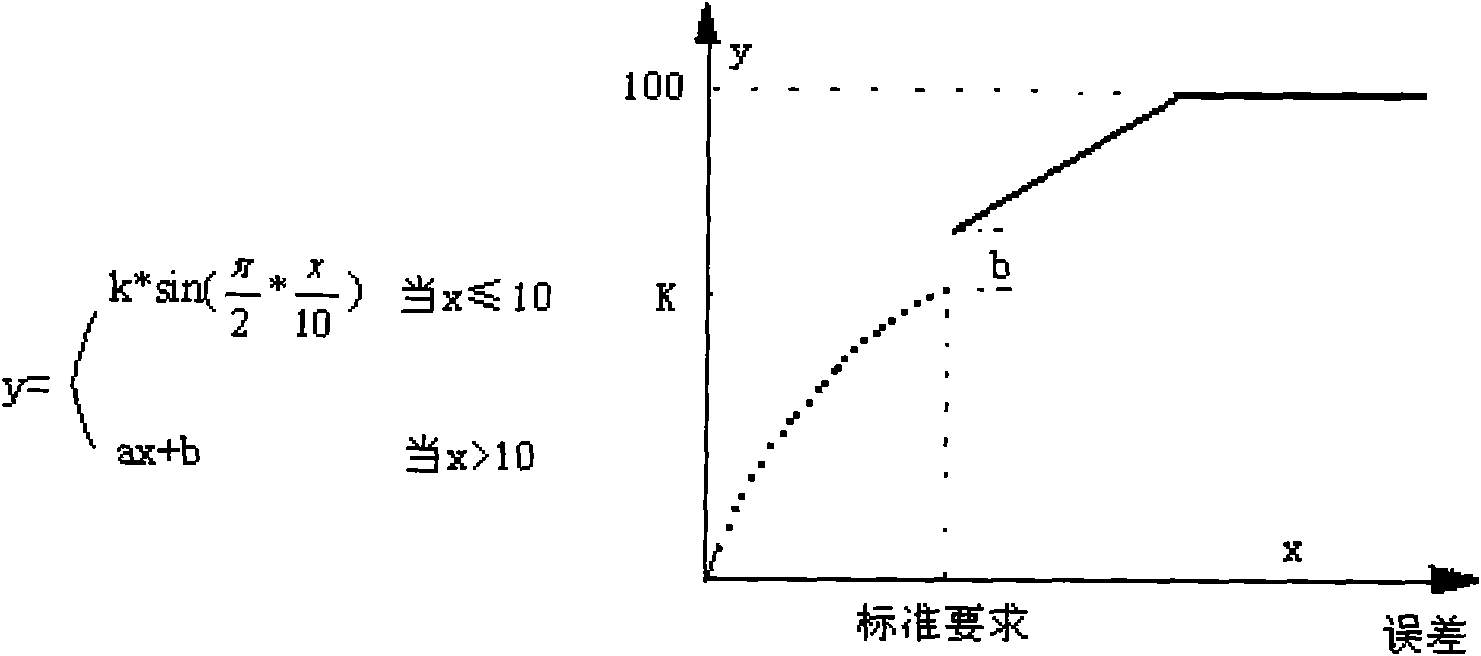

[0038] see figure 1 Shown, the test result evaluation method of fault recorder of the present invention specifically comprises the following steps:

[0039] (1) According to the test method stipulated in DL / T 663-1999 "220kV ~ 500kV Power System Fault Dynamic Recording Device Detection Requirements", we select the recording performance of non-periodic components for testing;

[0040] (2) Use a relay protection tester to conduct 5 non-periodic tests on a number of power system fault recorders connected to the network, and calculate the relative error (x%) of each time, without using the average error (to prevent positive and negative errors from offsetting) .

[0041] (3) Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com