Reciprocating type internal-combustion engine with low fuel oil and micro discharge

A micro-emission, reciprocating technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as low exhaust gas emissions, increased NOx emissions, and small clearances in combustion chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Taking diesel engine as example below, a kind of preferred embodiment of the present invention is described in detail:

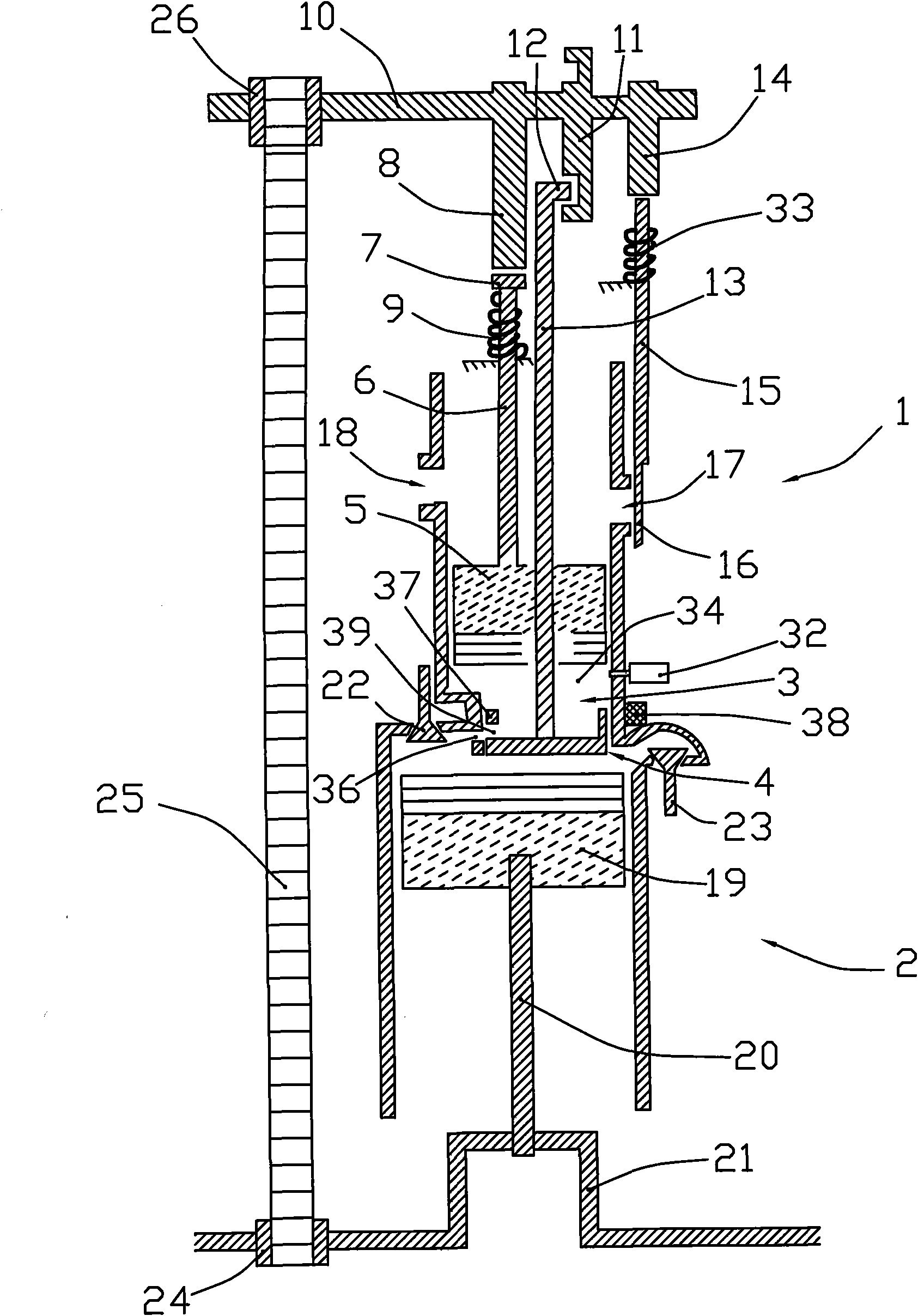

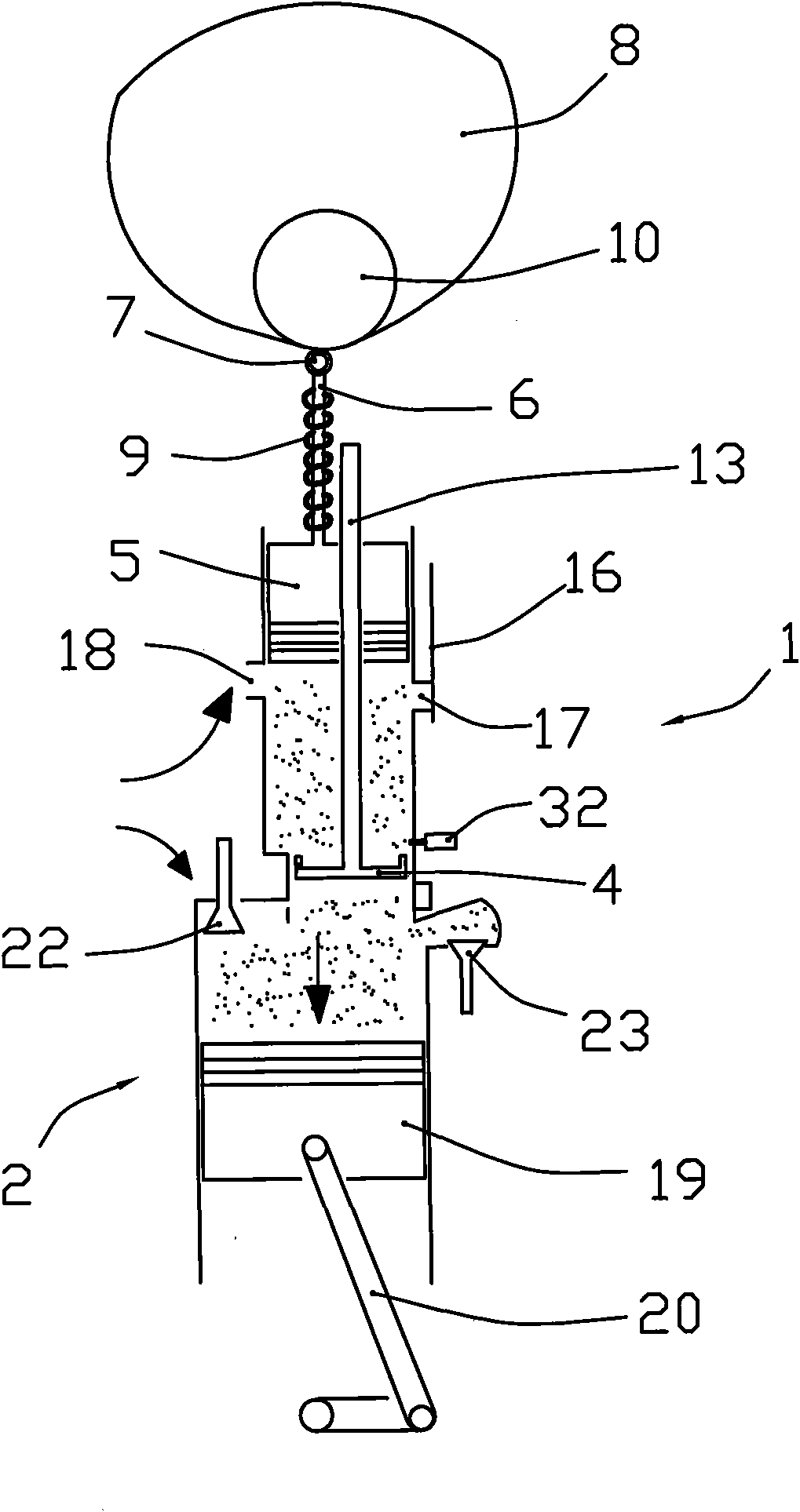

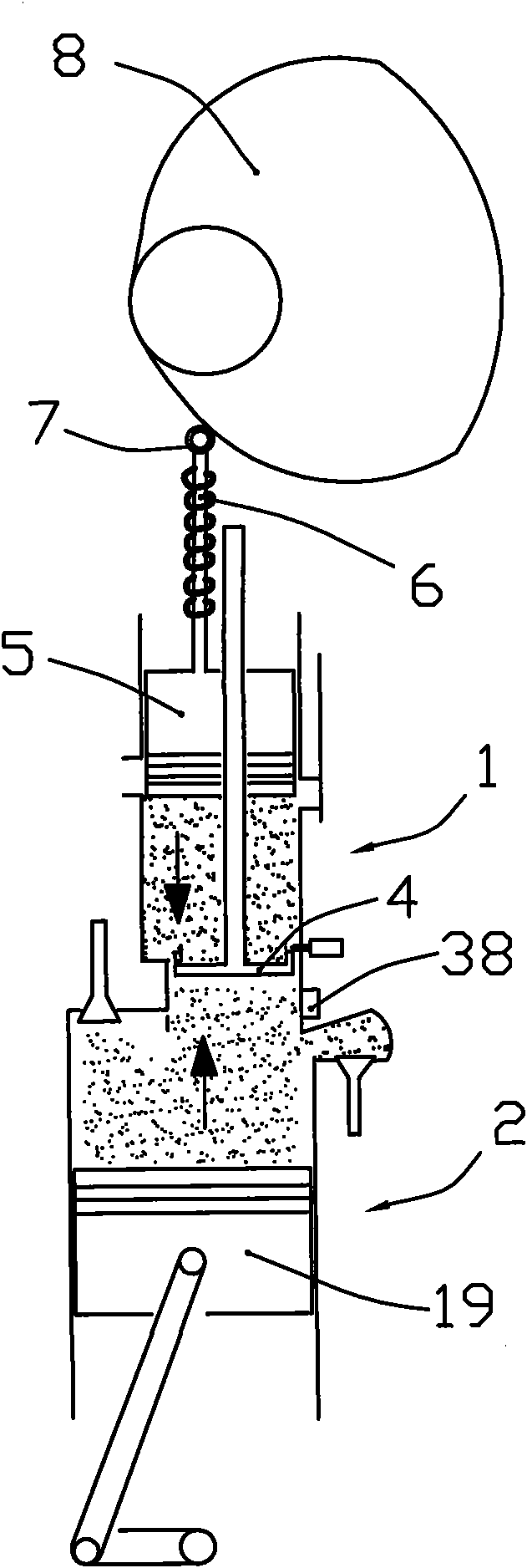

[0065] see figure 1, this embodiment mainly includes a combustion cylinder 1 , a power output cylinder 2 and a communication cylinder 3 . Wherein, the combustion cylinder 1 includes a combustion chamber 34, a combustion cylinder piston 5, a piston push rod 6, a roller 7, a piston compression cam 8, a piston return spring 9, an exhaust valve plate control cam 14, an exhaust valve plate push rod 15, Exhaust valve plate 16, exhaust valve plate return spring 33, combustion cylinder exhaust port 17, combustion cylinder scavenging air inlet 18 and fuel injection nozzle 32. The side surface of the combustion cylinder piston 5 is in sealing contact with the inner wall of the combustion cylinder 1 . The combustion cylinder scavenging air intake port 18 is arranged on the combustion cylinder 1 top, and the opening and closing of the combustion cylinder scaven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com