Method for preparing alginate soft capsule

An alginate gel, alginate technology, applied in microcapsule preparation, capsule delivery, microsphere preparation and other directions, can solve the problems of gelatin melting, easy rupture, aging, etc., and achieves small shrinkage and good firmness. , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

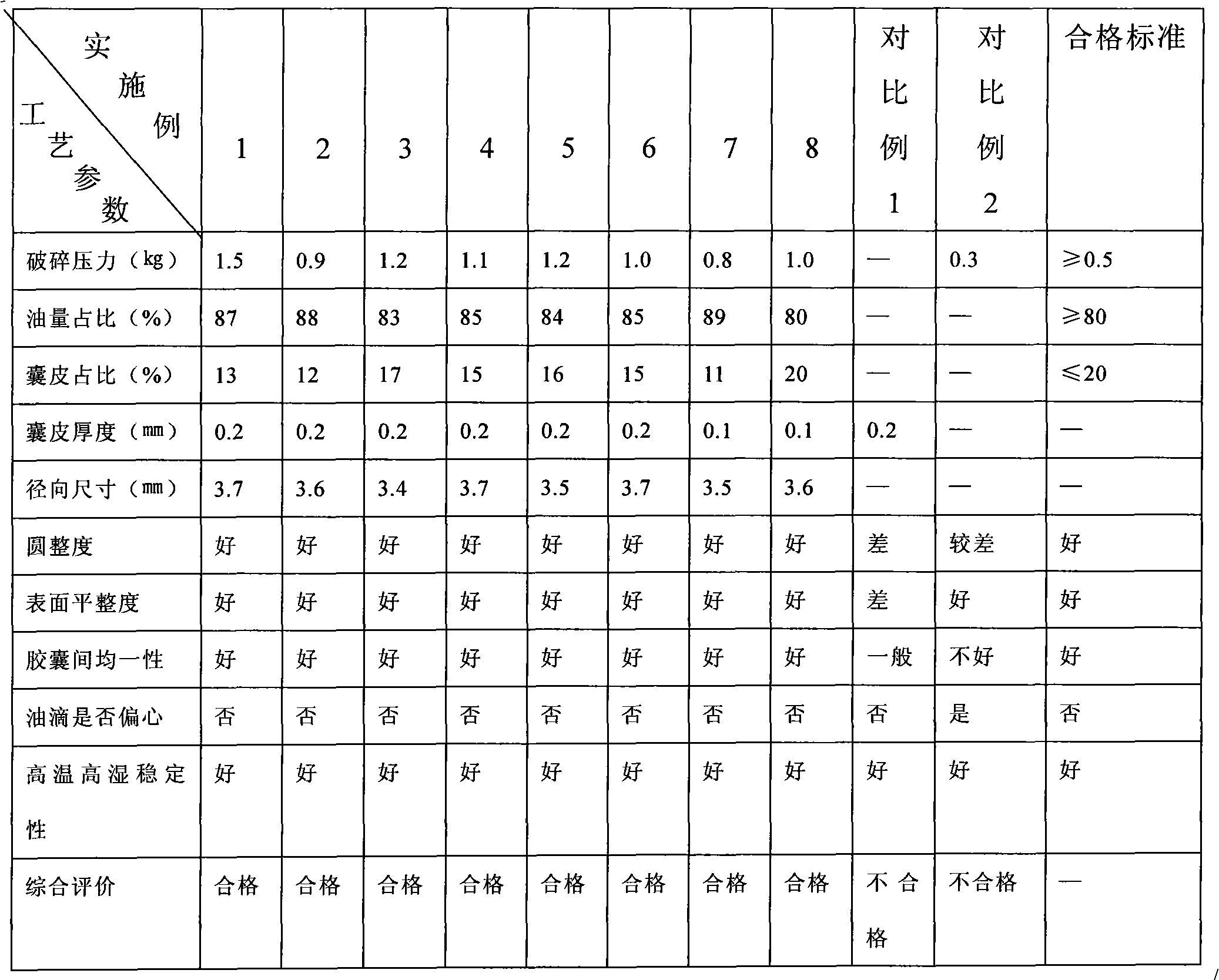

Examples

preparation example Construction

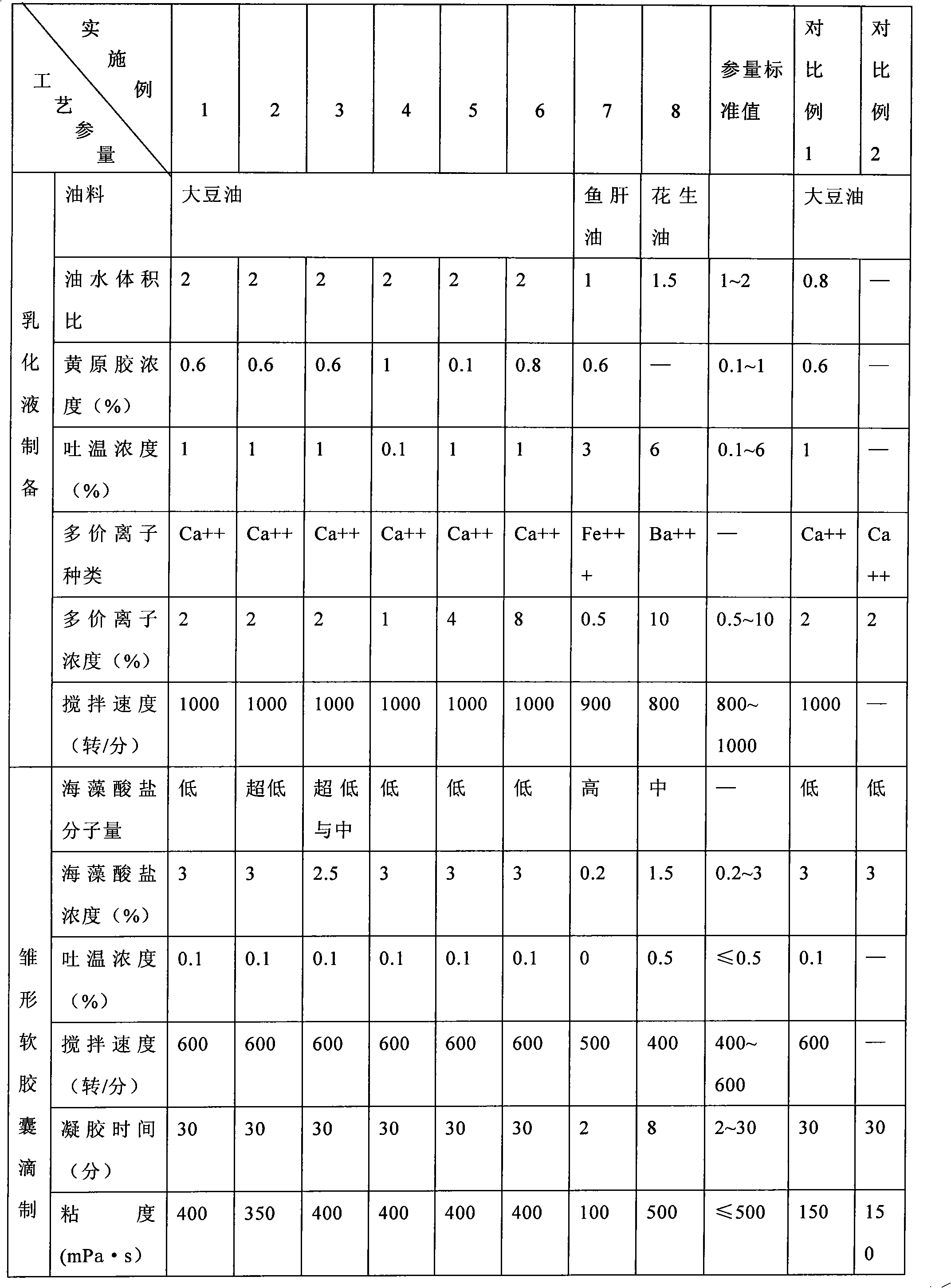

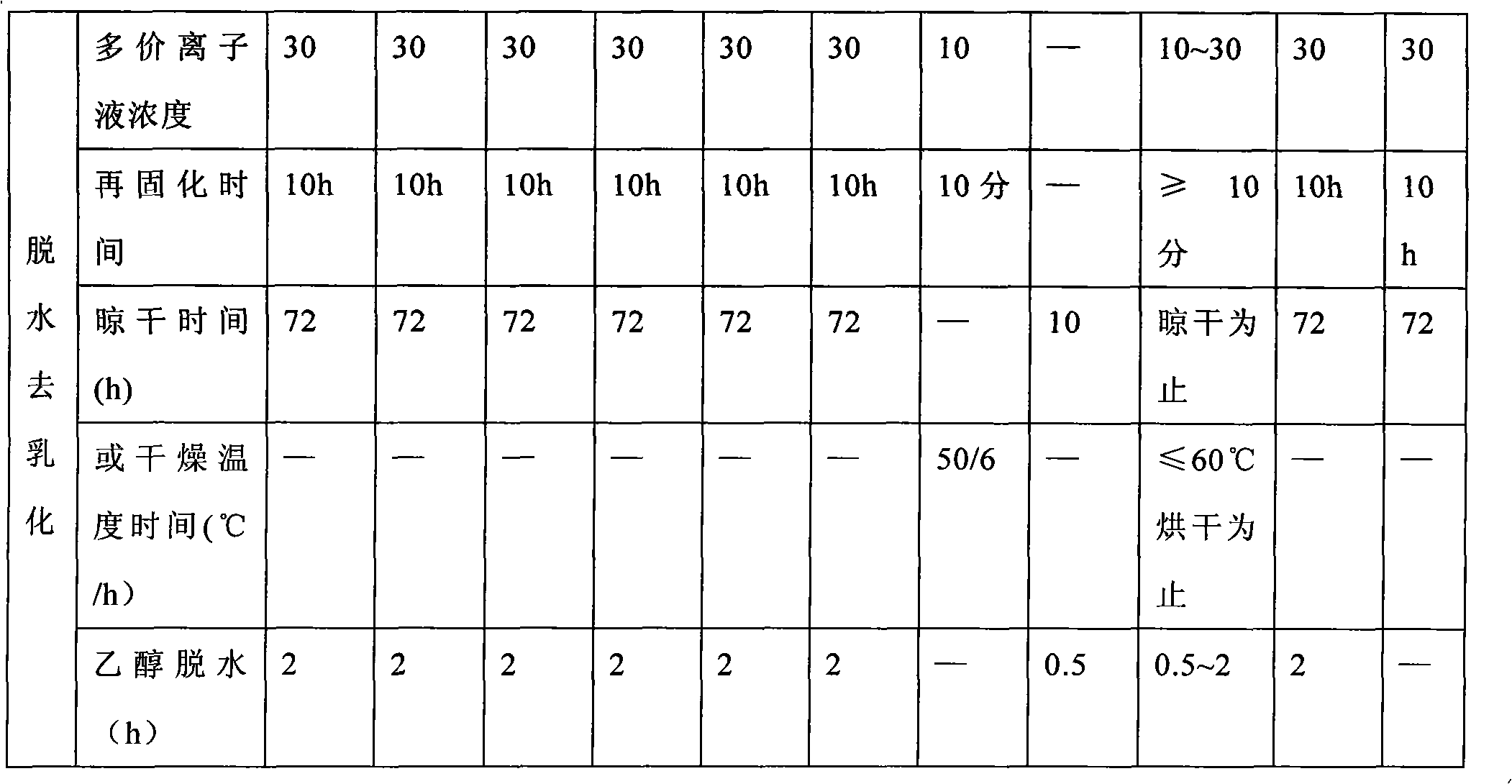

[0030] The steps of the invention include the preparation of the emulsion, dripping of the soft capsule and drying and dehydration of the soft capsule.

[0031] (1) Preparation of emulsion: drip and emulsify the oily liquid substance into the aqueous solution containing polyvalent metal ions under stirring (speed 800-1000 rpm) to form a high oil-water ratio oil-in-water emulsion. Wherein the polyvalent metal ion is a metal ion that reacts with a monovalent salt of alginic acid to form an insoluble gel;

[0032] The concentration (mass volume) of the multivalent metal ion aqueous solution is 0.5%~10%. If the concentration is too low, the gelation of the alginate is not enough, and if the concentration is too high, it will be wasteful and the stability of the formed emulsion will be too low; During the preparation process, since the emulsion droplets in the soft capsule made of emulsified liquid droplets will dehydrate and shrink in the subsequent de-emulsification process, the ...

Embodiment 1

[0042] (1), emulsion preparation: 1000mg calcium chloride, 300mg xanthan gum, 500mg Tween 80 are dissolved in 50ml water; 100ml soybean oil (being dissolved with 25g menthol) is slowly dripped in the above-mentioned calcium chloride mixed aqueous solution and Vigorous magnetic stirring (1000 rpm) to obtain a white oil-in-water emulsion;

[0043] (2), dripping of prototype alginate soft capsules: 30g sodium alginate (low molecular weight) and 1g Tween 80 are dissolved in 1000ml water to obtain a mixed aqueous solution with a viscosity of 400mPa·s; The emulsion was left to stand for 4 hours to remove air bubbles, dripped into the obtained mixed aqueous solution of sodium alginate under the state of stirring (600 rpm), stirred for 30 minutes after the end of the dripping, and carried out gelation reaction during stirring. Form a prototype alginate soft capsule that wraps emulsion droplets;

[0044] (3), dehydration and de-emulsification of the prototype alginate soft capsules: f...

Embodiment 2

[0048] Except that sodium alginate is ultra-low molecular weight sodium alginate used in step (2), and the usage amount is 30g (obtaining a mixed aqueous solution with a viscosity of 350mPa·s), all the other are the same as in Example 1.

[0049] The test results of the obtained calcium alginate soft capsules are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com