Method for preparing textured ZnO membrane with pyramid-like structure

A pyramid structure, suede technology, applied in the field of solar cells, can solve the problems of expensive raw materials, waste of film materials, and high risk of suede ZnO films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

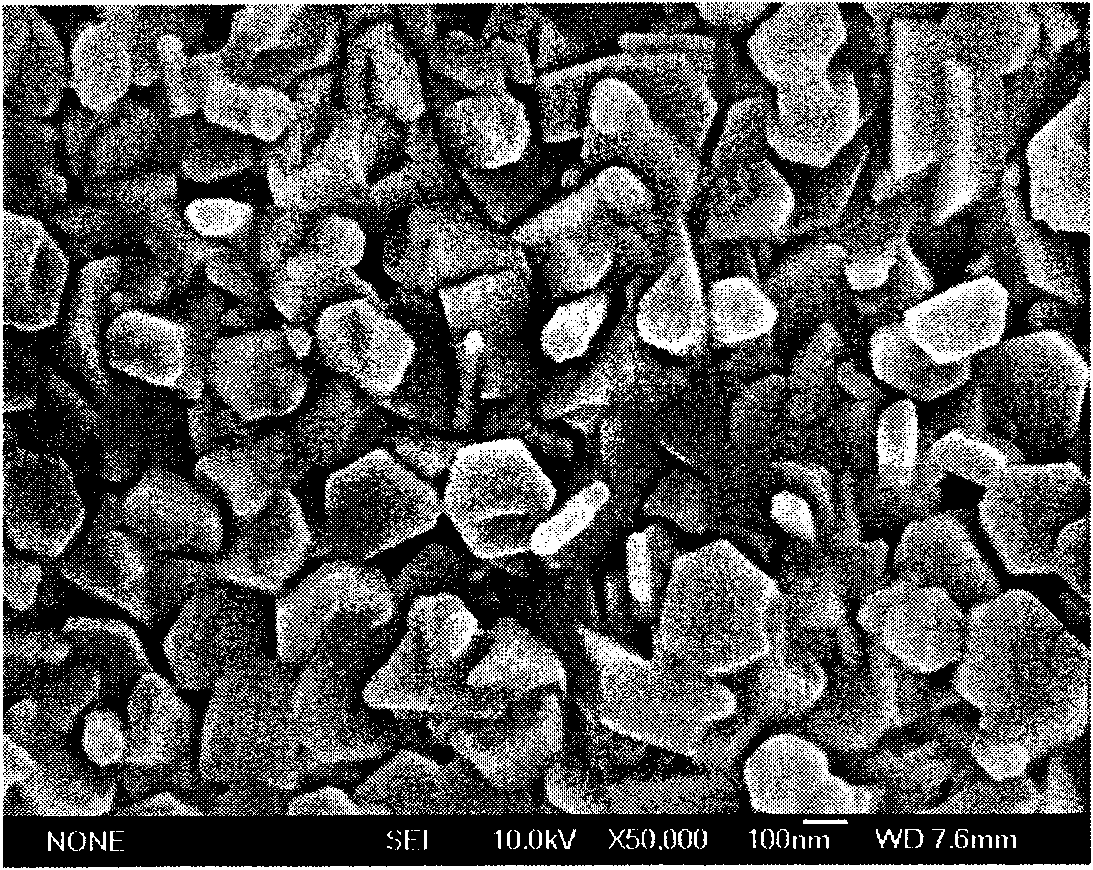

[0017] Zinc acetate is used as Zn source, and indium nitrate is used as doped indium source. Water and absolute ethanol were mixed at a ratio of 1:3 as a solvent, and zinc acetate and indium nitrate were respectively configured into 0.1 mol / L solutions. Zinc acetate and indium nitrate solution are mixed according to Zn:In=1:0.03 (atomic percentage), and then glacial acetic acid is added thereto according to the volume ratio of zinc acetate solution to glacial acetic acid at 1:0.1. Ordinary glass (Na 2 O: CaO: SiO 2 = 1:1:6) as the substrate. The growth temperature was 480°C. High purity N 2 (purity is 99.999%) as carrier gas, grows 60min, the thickness that obtains sample is 280nm, obtains the surface appearance that has certain surface roughness ZnO thin film such as figure 1 ;

Embodiment 2

[0019] Zinc acetate is used as Zn source, and indium nitrate is used as doped indium source. Water and absolute ethanol were mixed at a ratio of 1:3 as a solvent, and zinc acetate and indium nitrate were respectively prepared into 0.2 mol / L solutions. Zinc acetate and indium nitrate solution are mixed according to Zn:In=1:0.03 (atomic percentage), and then glacial acetic acid is added thereto according to the volume ratio of zinc acetate solution to glacial acetic acid at 1:0.1. Ordinary glass (Na2O:CaO:SiO2=1:1:6) was used as the substrate. The growth temperature was 480°C. Air is used as the carrier gas, grown for 60min, the thickness of the obtained sample is 549nm, and the morphology of the obtained ZnO thin film is as follows figure 2 , it is obvious that ZnO thin films with pyramid-like morphology were synthesized.

Embodiment 3

[0021] Zinc acetate was used as Zn source, and aluminum nitrate was used as doped aluminum source. Using water as a solvent, zinc acetate and aluminum nitrate were prepared into 0.3mol / L and 0.05mol / l solutions respectively. The zinc acetate and aluminum nitrate solutions were mixed according to Zn:In=1:0.05 (atomic percentage). Ordinary glass (Na2O:CaO:SiO2=1:1:6) was used as the substrate. The growth temperature was 360°C. High-purity N2 (purity is 99.999%) is used as carrier gas, grows 40min, the thickness that obtains sample is 50nm, obtains the surface morphology of ZnO thin film with certain surface roughness such as image 3 ;

[0022] In summary, the present invention controls the reaction deposition parameters, adopts low-cost ultrasonic spray pyrolysis technology, and uses cheap and non-toxic chemicals to directly synthesize a transparent conductive film with a pyramid-like texture for solar cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com