Optical spin injection method

A spin injection and optical technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as low temperature operation, low spin injection efficiency, and low spin polarization. Achieve the effects of easy integration, practicality, and easy room temperature operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

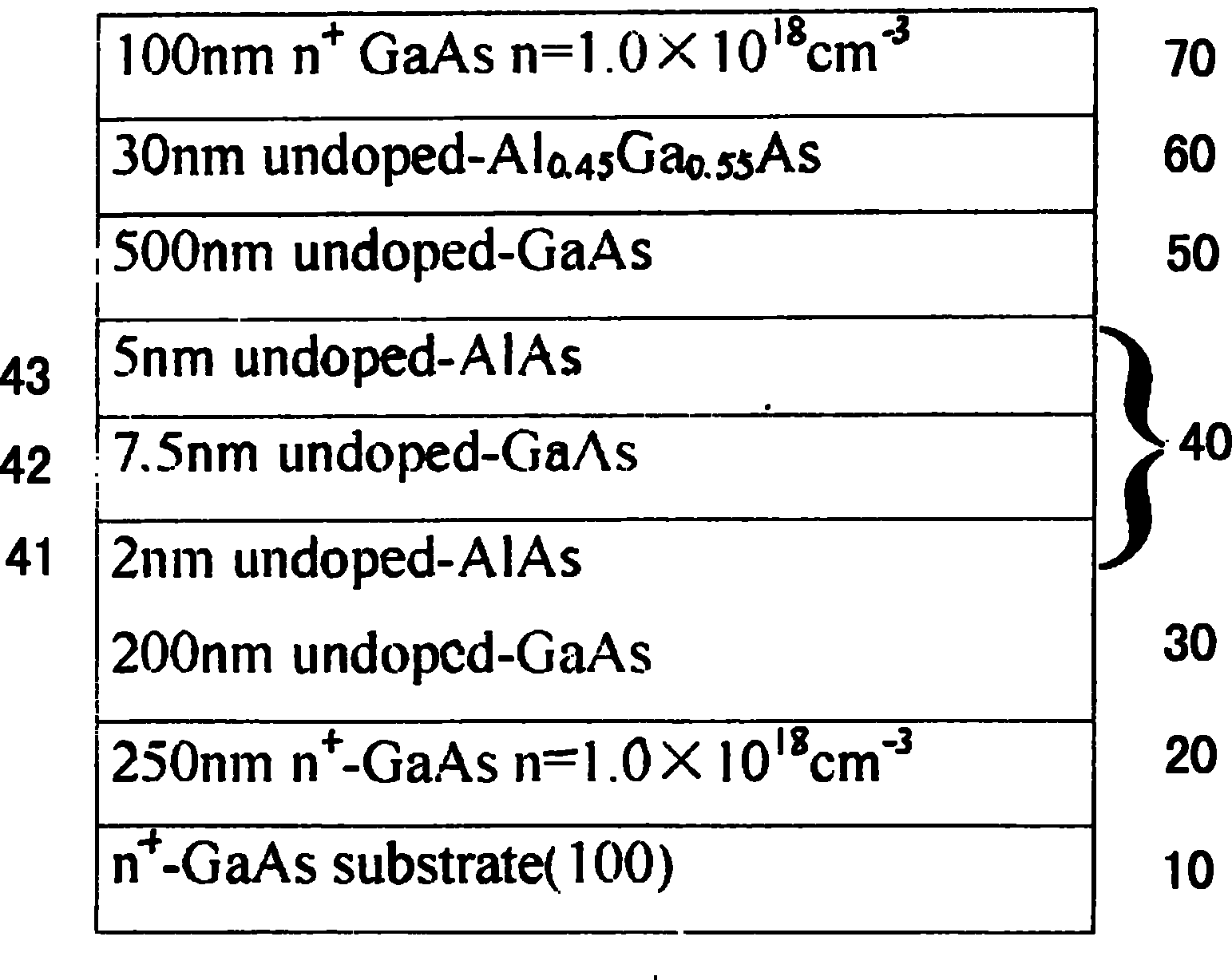

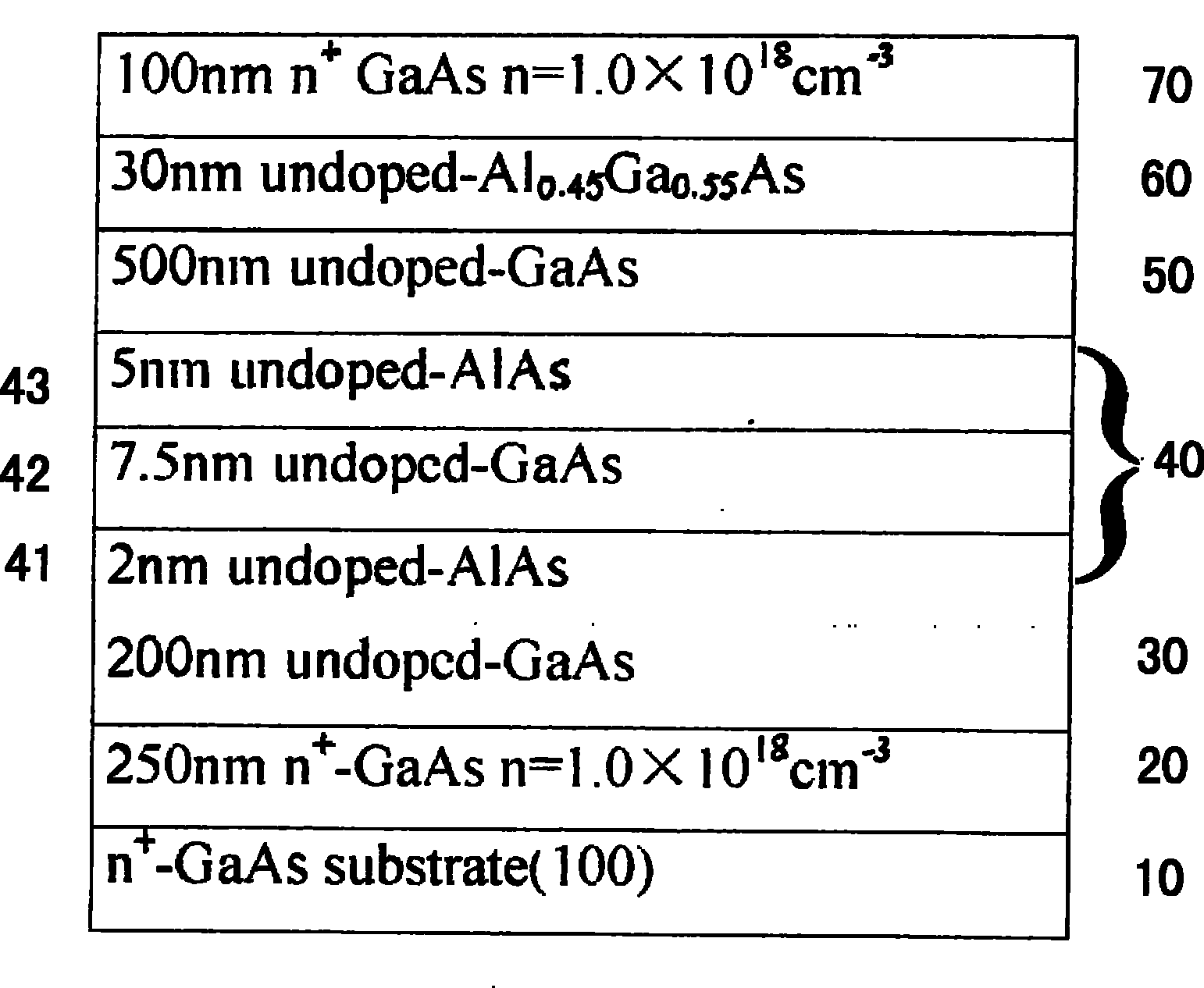

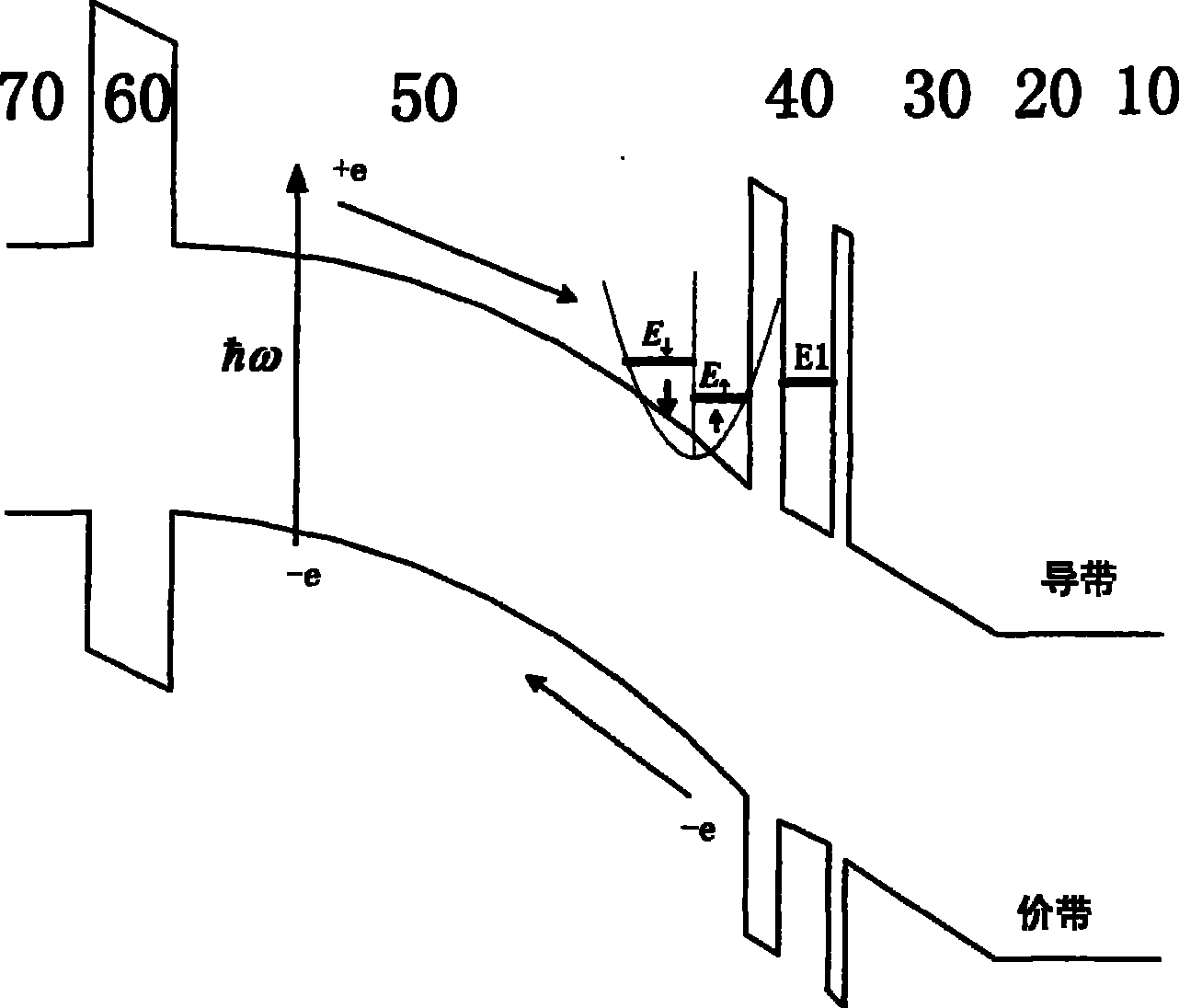

[0025] Please refer to FIG. 1, which is a hierarchical structure diagram of materials involved in the present invention. Wherein a heavily doped GaAs substrate 10 is selected; a buffer layer 20 is grown on it, the thickness of the buffer layer 20 is 250nm, the material of the buffer layer 20 is heavily doped GaAs, and the buffer layer 20 can smooth the substrate, The subsequent growth of the epitaxial structure has fewer dislocations and a more complete lattice, ensuring its excellent optical and electrical properties. Then grow a layer of active layer 30, the thickness of the active layer 30 is 200nm, the material of the active layer 30 is GaAs, the inside of the active layer 30 can be embedded with quantum wells or quantum dots, to tunnel the self Spin manipulation of spin-polarized electrons. Thereafter, a layer of resonant tunneling structure 40 is grown, and the resonant tunneling structure 40 functions as a spin filter, so that the polarization degree of spin-polarized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com