Surface roughness on line measurement method under uncertain condition

A surface roughness and measurement method technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of deviation and change of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

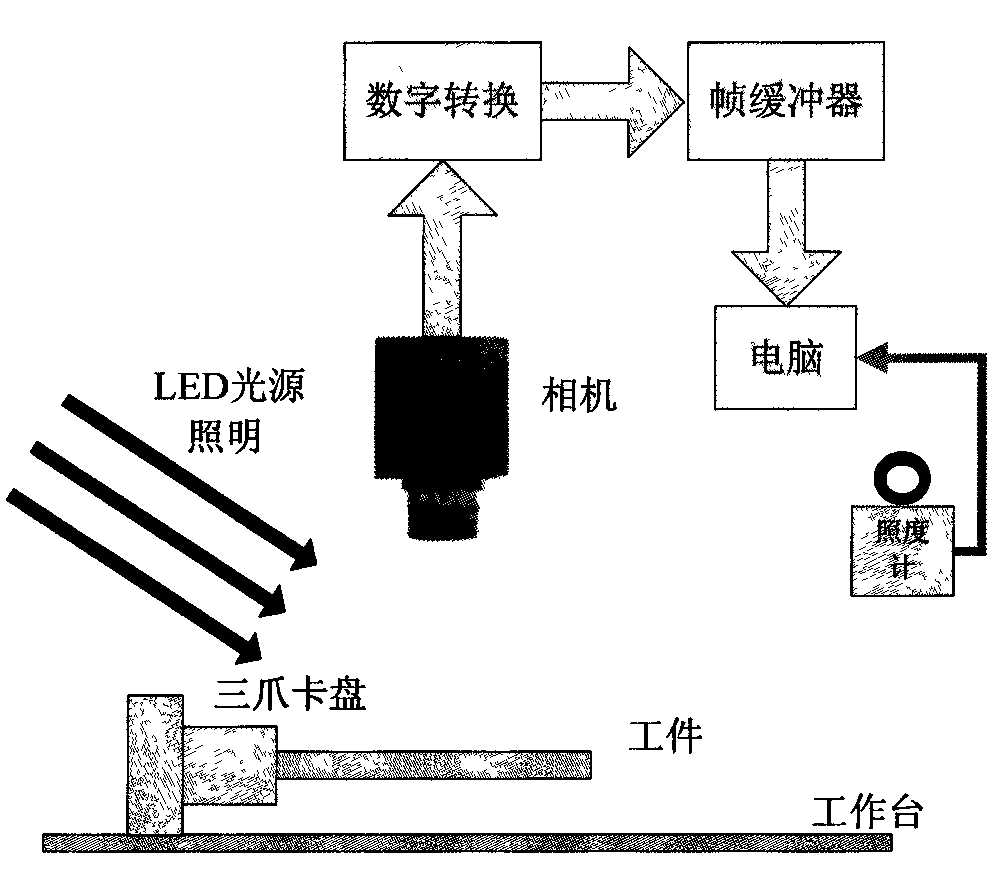

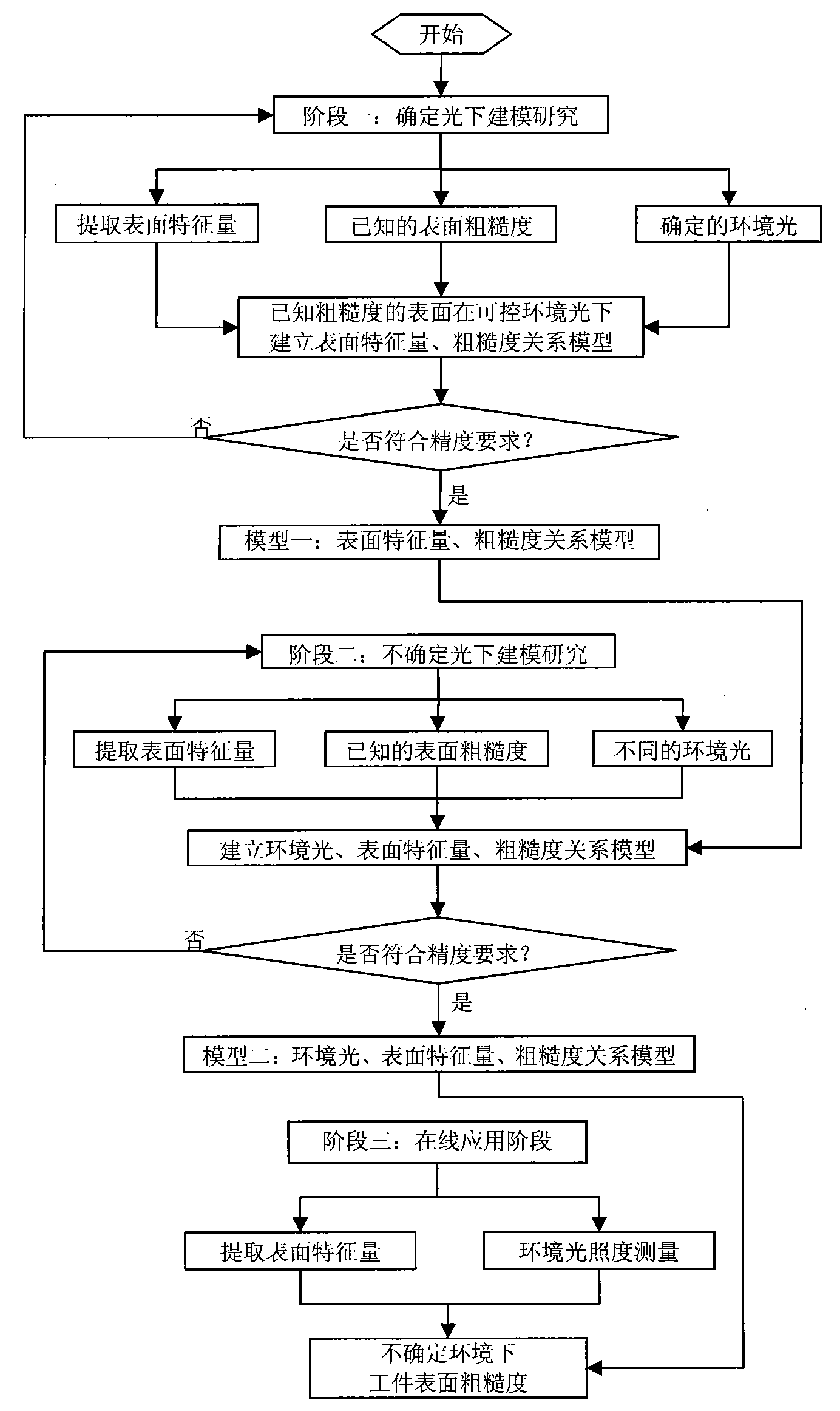

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] (1) Determine the modeling under light:

[0048] A. Take the first workpiece with a surface roughness value of 0.12 μm and place it on the production site; adjust the on-site LED light source so that the ambient light brightness value is 230Lux at this time, use a CCD camera to obtain an image of the workpiece surface, and convert the acquired image to grayscale image;

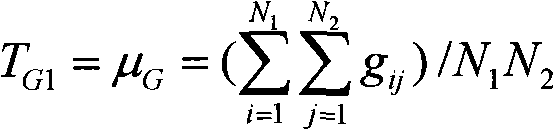

[0049] B. According to the grayscale image obtained in step A, extract the grayscale mean μ of the sampling area G As the first feature quantity T of the first workpiece surface image G1 ,Calculated as follows:

[0050] T G 1 = μ G = ( Σ i = 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com