Vacuum nitrogen oven

A nitrogen and vacuum technology, used in drying, dryers, lighting and heating equipment, etc., can solve the problems of low baking efficiency and long cooling time, and achieve improved drying efficiency, good air tightness, and shortened drying time. The effect of the bake cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

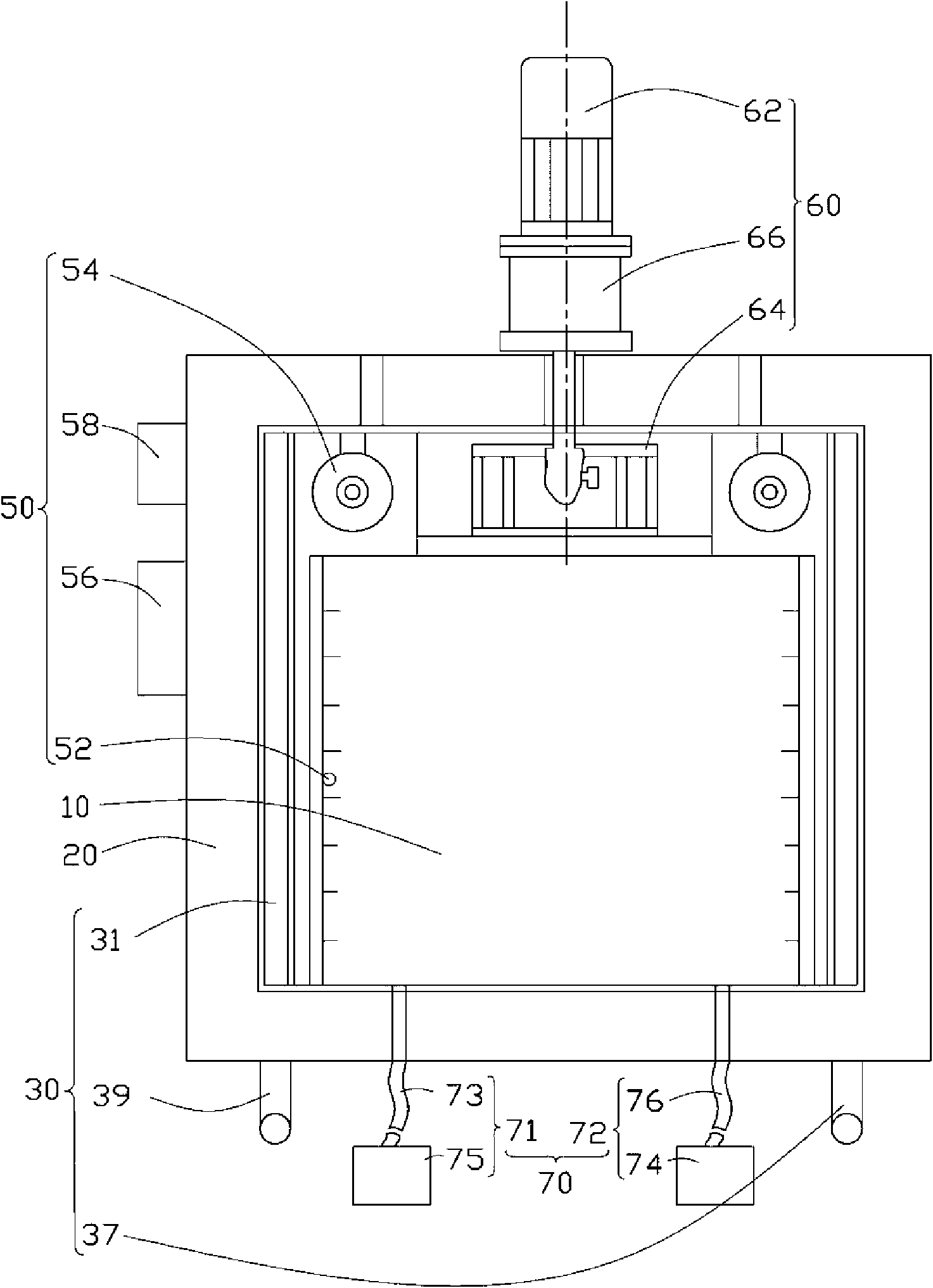

[0012] figure 1 It is a cross-sectional view of the structure of the vacuum nitrogen oven provided in this embodiment, which includes: a box body 10 , an insulating outer wall 20 , a temperature control device 50 , a circulating air device 60 , a gas transfer device 70 and a cooling device 30 .

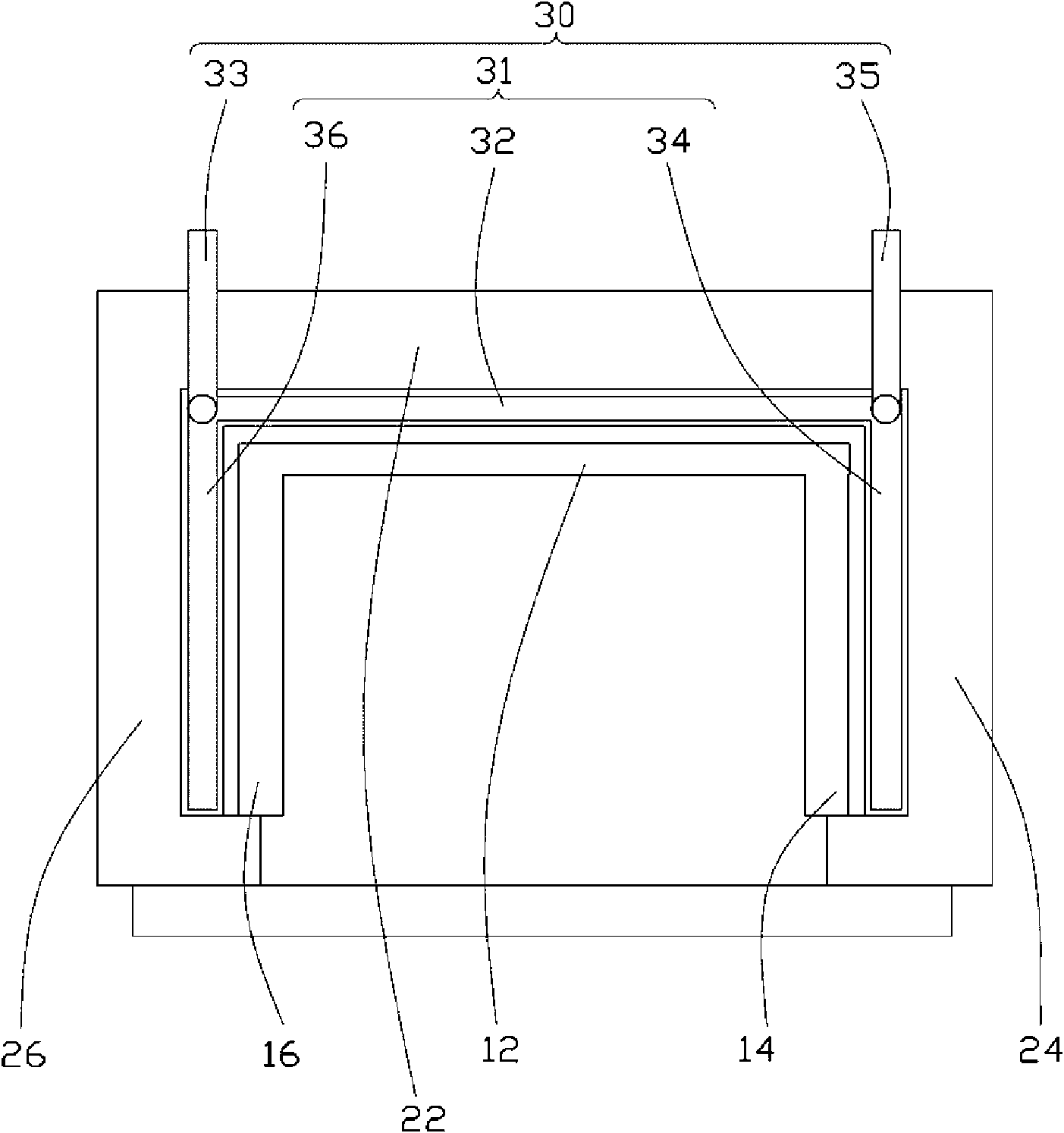

[0013] refer to figure 2 The box body 10 includes a first side wall 12 , a second side wall 16 and a third side wall 14 , and the first side wall 12 , the second side wall 16 and the third side wall 14 form a cavity.

[0014] The heat insulating outer wall 20 is arranged around the box body 10 and has a first side wall 22, a second side wall 26 and a first side wall 22 corresponding to the first side wall 12, the second side wall 16 and the third side wall 14 of the box body 10 respectively. The third side wall 24 . A cooling device 30 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com