Novel thermal circulation system

A thermodynamic cycle system, a new type of technology, applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of intermittent system work and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

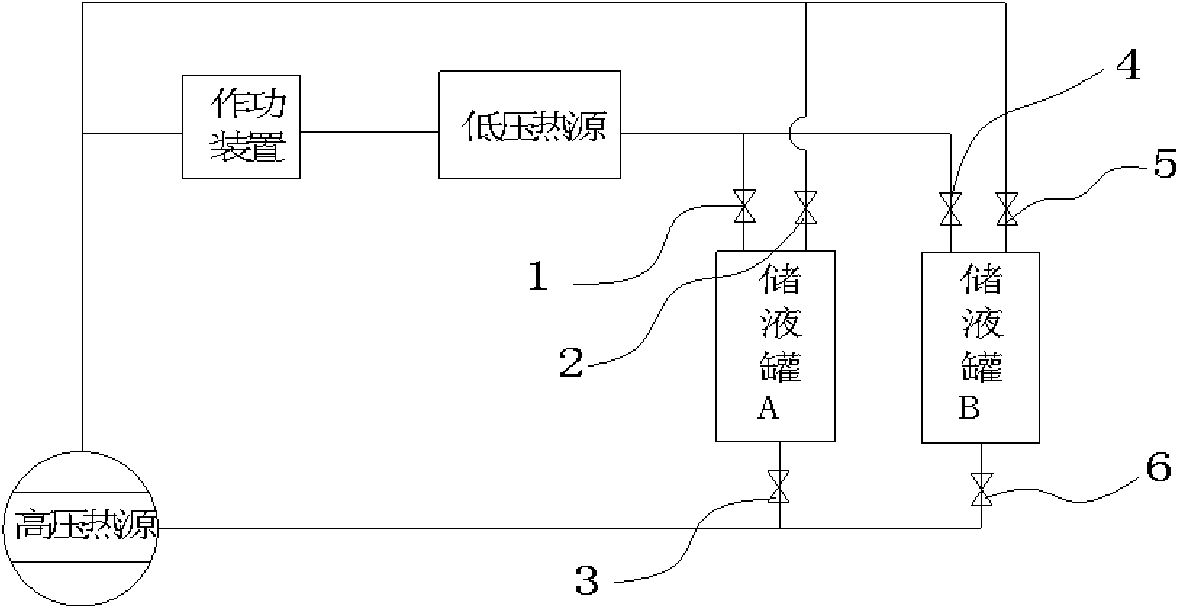

[0018] Embodiment one, such as figure 1 As shown, the parallel circulation system, the system is in the initial state, the stop valve five (5), the stop valve one (1), the stop valve six (6) are closed, and the stop valve four (4), the stop valve two (2), Stop valve three (3), after a period of time, close stop valve two (2) and stop valve three (3), let the liquid storage tank A cool naturally, after the high-pressure heat source, that is, the high-pressure generator is heated, the medium pressure rises, and the inside of the pipe A high-pressure, high-speed airflow is formed.

[0019] The high-pressure and high-speed air flows through the working device, that is, the energy conversion device, to the low-pressure end. After passing through a low-pressure heat source such as a cooling refrigerator, the medium enters the liquid storage tank B in a liquid state. When the liquid volume of the liquid storage tank B reaches a certain amount, the cut-off is opened. Valve five (5), ...

Embodiment 2

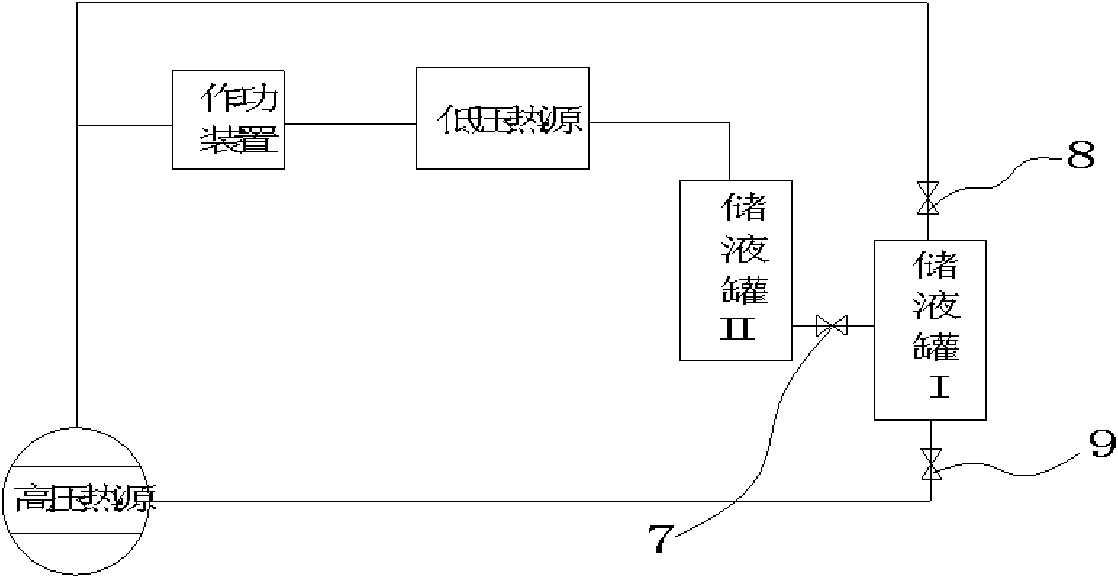

[0021] Embodiment two, such as figure 2 As shown, the initial position of the system is that stop valve eight (8) and stop valve nine (9) are closed, and stop valve seven (7) is opened. After the high-pressure generator is heated, the pressure of the medium rises, and a high-pressure and high-speed airflow is formed in the pipe, and the airflow passes through to do work. The energy conversion of the device reaches the low-pressure heat source. After cooling the refrigerator, the medium becomes liquid. The liquid medium enters the liquid storage tank II and finally reaches the liquid storage tank I. When the liquid medium in the liquid storage tank I reaches the set amount, it is closed. Stop valve seven (7), now open stop valve eight (8) and stop valve nine (9), liquid storage tank I and high-pressure generator pressure balance, also because of the difference in the specific gravity of the liquid medium due to the presence of terrain position height difference, medium Return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com