Melt spinning head for multi-composition hollow fiber composite membrane

A fiber composite and spinneret technology, which is applied in the production of hollow filaments, fiber processing, fiber chemical characteristics, etc., can solve the problem of not meeting the requirements of use, and achieve the effect of uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

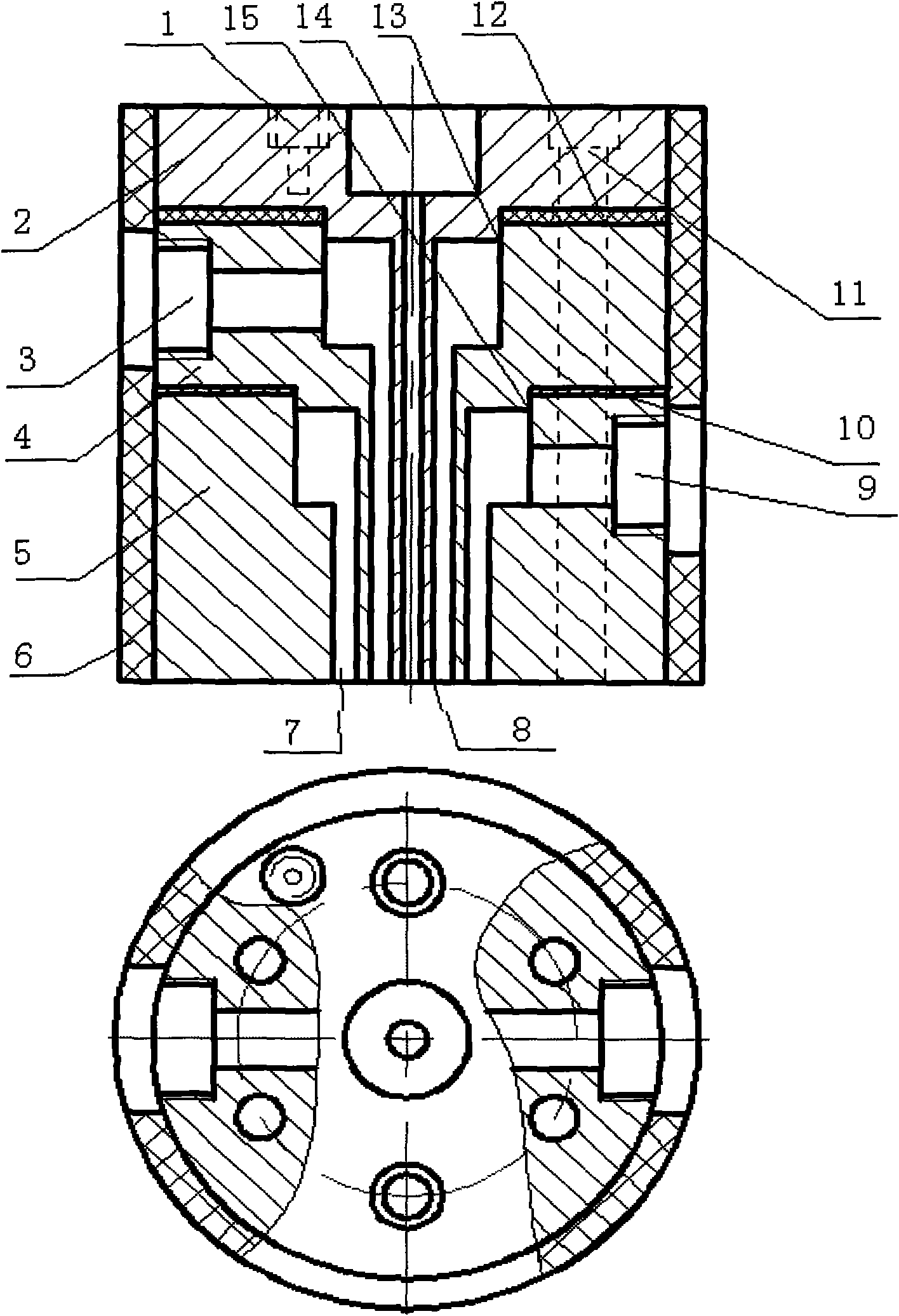

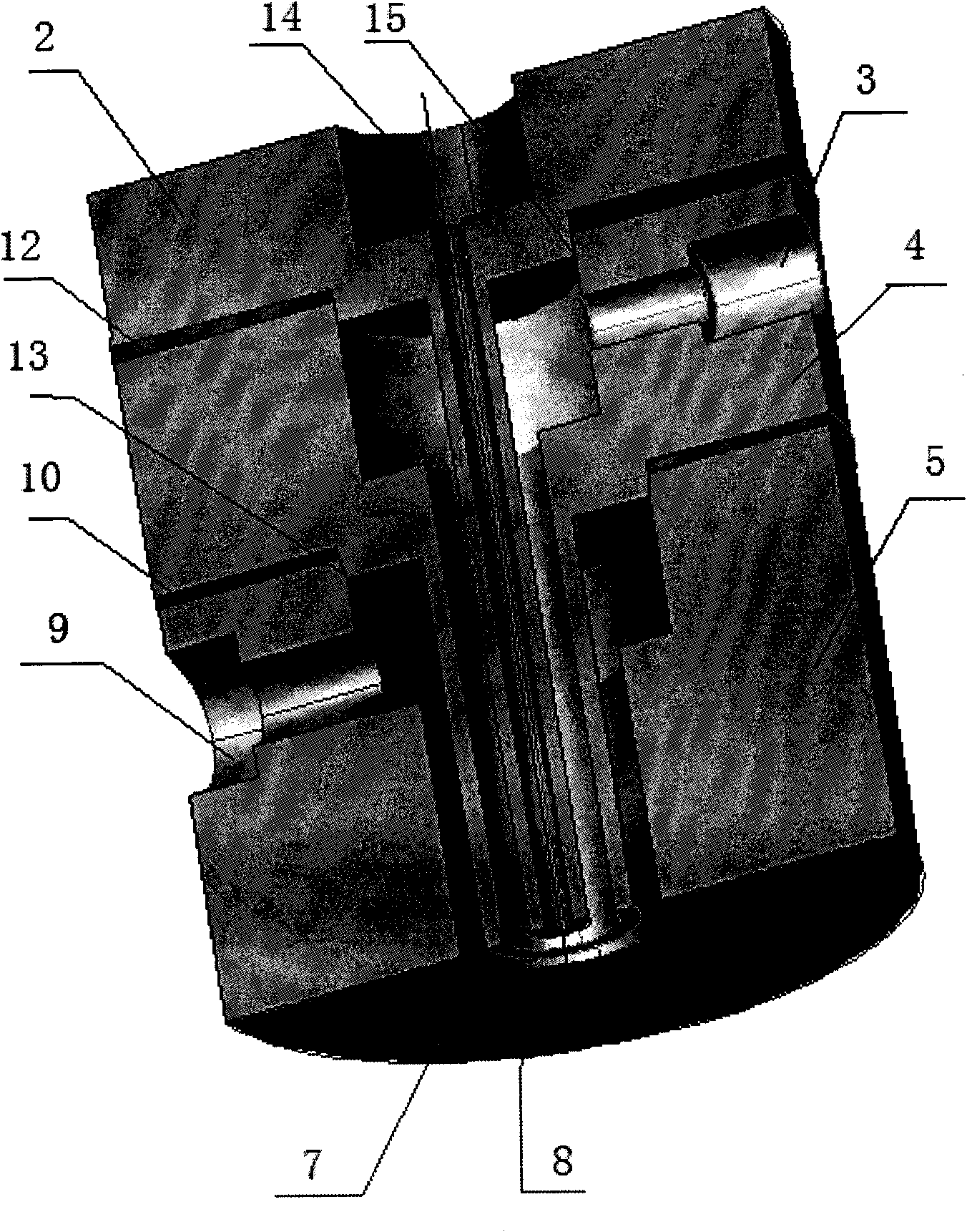

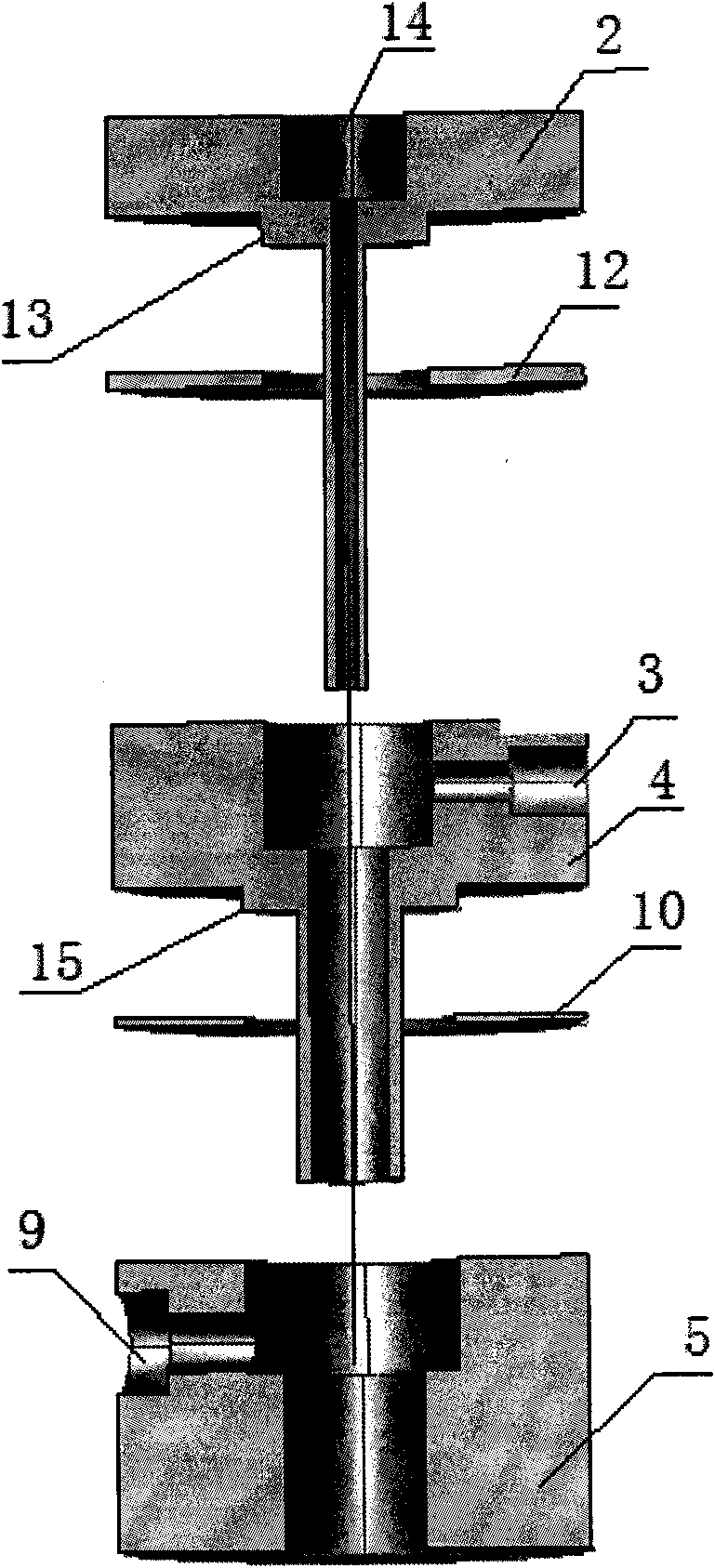

[0015] figure 1 Schematic representation of an embodiment of a multicomponent melt spinning spinneret of the present invention. figure 2 The direct section structural diagram of the main part of the embodiment of the multi-component melt spinneret of the present invention; image 3 The assembly diagram of the main part of the embodiment of the multi-component melting spinneret of the present invention;

[0016] Multiple spinning devices provide multi-component high polymers, and form multi-component melt-spun hollow fiber composite membranes through connectors and a spinneret. Composite membranes include double and multiple skin layers.

[0017] A plurality of spinning devices arranged in parallel produce melt films respectively. For this purpose, one spinneret is used in several spinning units, whereby hollow fiber composite membranes can be spun in one go by means of several spinning units. A set of spinneret and heat preservation device, the design requirements of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com