Method for preparing vanadium oxide film by metal oxidation method

A technology of vanadium oxide thin film and oxidation method, which is applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of complex process and many control parameters, and achieves simple process, expanded preparation method, and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of Si 3 N 4 Process conditions: Body vacuum: 4.5×10 -1 Pa; working gas: NH 4 and with N 2 Diluted SiH 4 ; Working pressure: 4.3Pa; NH 4 and with N 2 Flow rate: 12ml / min and 38ml / min; substrate temperature: 100°C, deposition for 12 minutes. Si 3 N 4 Approx. Si was grown on the surface 3 N 4 The first-layer silicon wafer is cut into a rectangular substrate with a size of 2cm×1cm for plating metal vanadium thin film;

[0024] (2) Si obtained by step (1) 3 N 4 The substrate is placed in the vacuum chamber of the DPS-III type ultra-high vacuum target magnetron sputtering equipment. Metal vanadium with a mass purity of 99.9% is used as the target material, and argon gas with a mass purity of 99.999% is used as the working gas. Take the background vacuum as 5×10 -4 Pa, the sputtering working pressure is 1Pa, the sputtering time is 20min, the Ar gas flow rate is 48ml / min, and the metal vanadium thin film is prepared.

[0025] (3) the metal vanad...

Embodiment 2

[0029] (1) Preparation of Si 3 N 4 Process conditions: Body vacuum: 4.5×10 -1 Pa; working gas: NH 4 and with N 2 Diluted SiH 4 ; Working pressure: 4.3Pa; NH 4 and with N 2 Flow rate: 12ml / min and 38ml / min; substrate temperature: 100°C, deposition for 12 minutes. Si 3 N 4 Approx. Si was grown on the surface 3 N 4 The first-layer silicon wafer is cut into a rectangular substrate with a size of 2cm×1cm for plating metal vanadium thin film;

[0030] (2) Si obtained by step (1) 3 N 4 The substrate is placed in the vacuum chamber of the DPS-III type ultra-high vacuum target magnetron sputtering equipment. Metal vanadium with a mass purity of 99.9% is used as the target material, and argon gas with a mass purity of 99.999% is used as the working gas. Take the background vacuum as 5×10 -4 Pa, the sputtering working pressure is 2Pa, the sputtering time is 10min, the Ar gas flow rate is 48ml / min, and the metal vanadium thin film is prepared.

[0031] (3) the metal vanad...

Embodiment 3

[0035] (1) Preparation of Si 3 N 4 Process conditions: Body vacuum: 4.5×10 -1 Pa; working gas: NH 4 and with N 2 Diluted SiH 4 ; Working pressure: 4.3Pa; NH 4 and with N 2 Flow rate: 12ml / min and 38ml / min; substrate temperature: 100°C, deposition for 12 minutes. Si 3 N 4 Approx. Si was grown on the surface 3 N 4 The first-layer silicon wafer is cut into a rectangular substrate with a size of 2cm×1cm for plating metal vanadium thin film;

[0036] (2) Si obtained by step (1) 3 N 4The substrate is placed in the vacuum chamber of the DPS-III type ultra-high vacuum target magnetron sputtering equipment. Metal vanadium with a mass purity of 99.9% is used as the target material, and argon gas with a mass purity of 99.999% is used as the working gas. Take the background vacuum as 5×10 -4 Pa, the sputtering working pressure is 2Pa, the sputtering time is 20min, the Ar gas flow rate is 48ml / min, and the metal vanadium thin film is prepared.

[0037] (3) the metal vanadi...

PUM

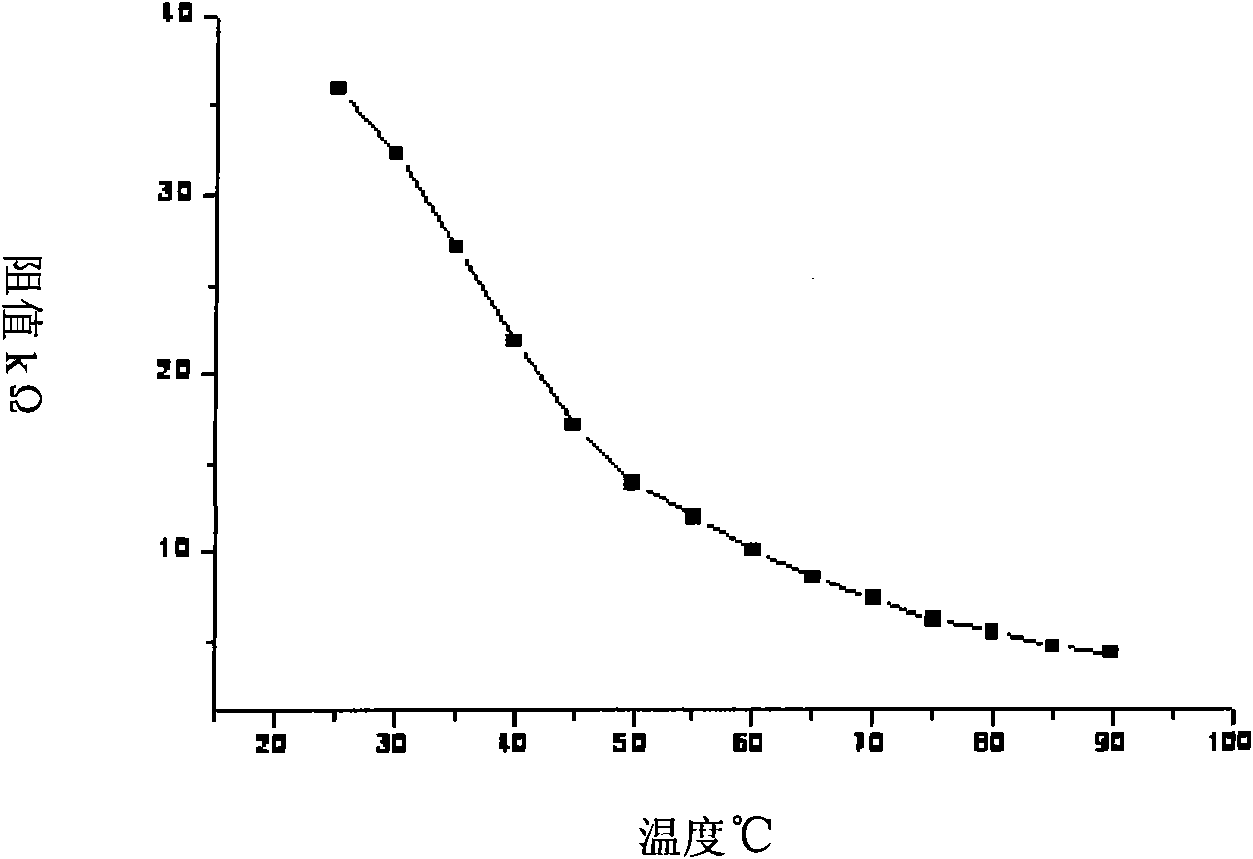

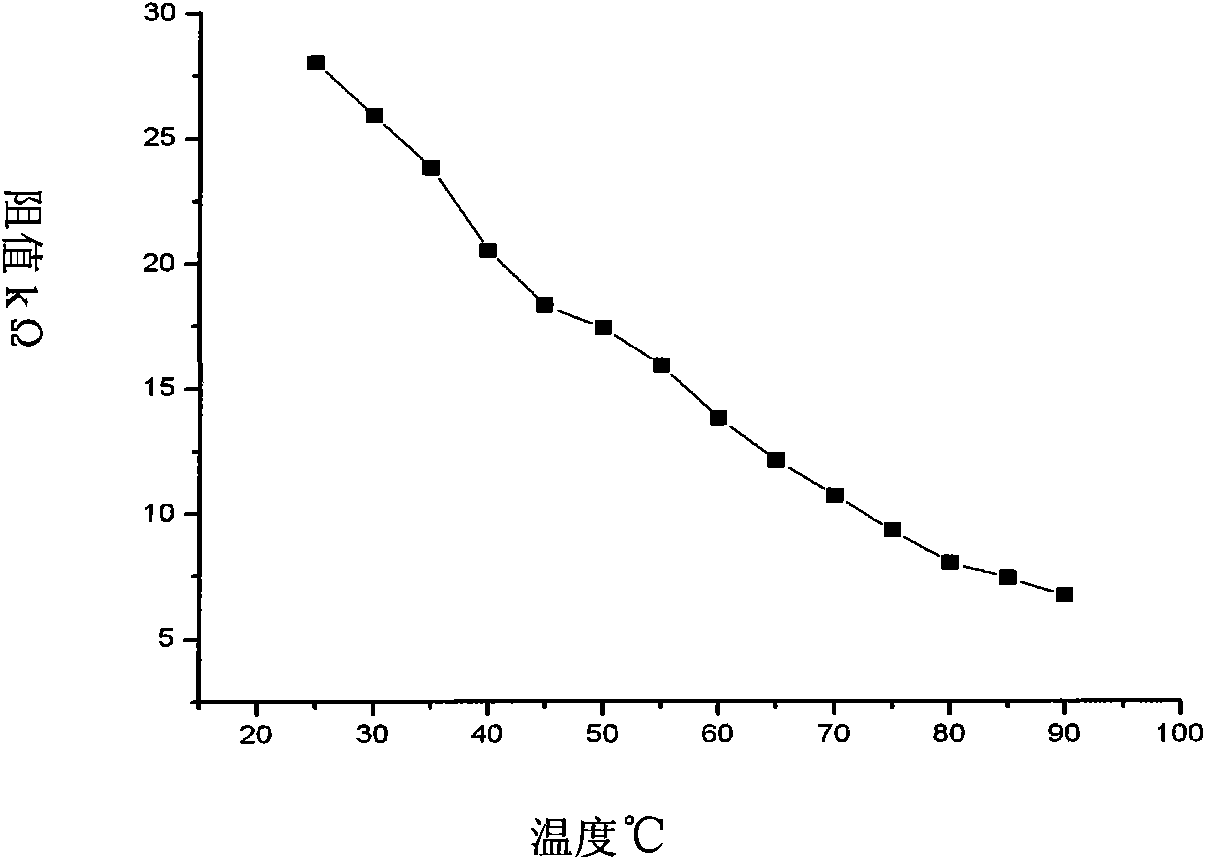

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com