Fermentation method of microbial polysaccharide flocculant

A microbial polysaccharide and biological flocculant technology, applied in the field of modern microbial engineering, can solve the problems of long fermentation period, high raw material cost and production cost, waste of water resources, etc., and achieve the effect of strong flocculation function, large aggregation and adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a) Preparation of fermentation medium

[0032] Mass composition of fermentation medium (g / L):

[0033] Starch sugar 20, (NH 4 ) 2 SO 4 4,K 2 HPO 4 6. MgSO 4 0.8, CaCl 2 1.3, corn syrup 1.3, water 1000.

[0034] Get 15% of the fermentation water for preparation (NH 4 ) 2 SO 4 Components, 85% of the fermentation water is used to prepare other components, which are respectively sterilized at 120°C for 8 minutes and then mixed in the fermenter for later use:

[0035] b) Fermentation method and fermentation condition control

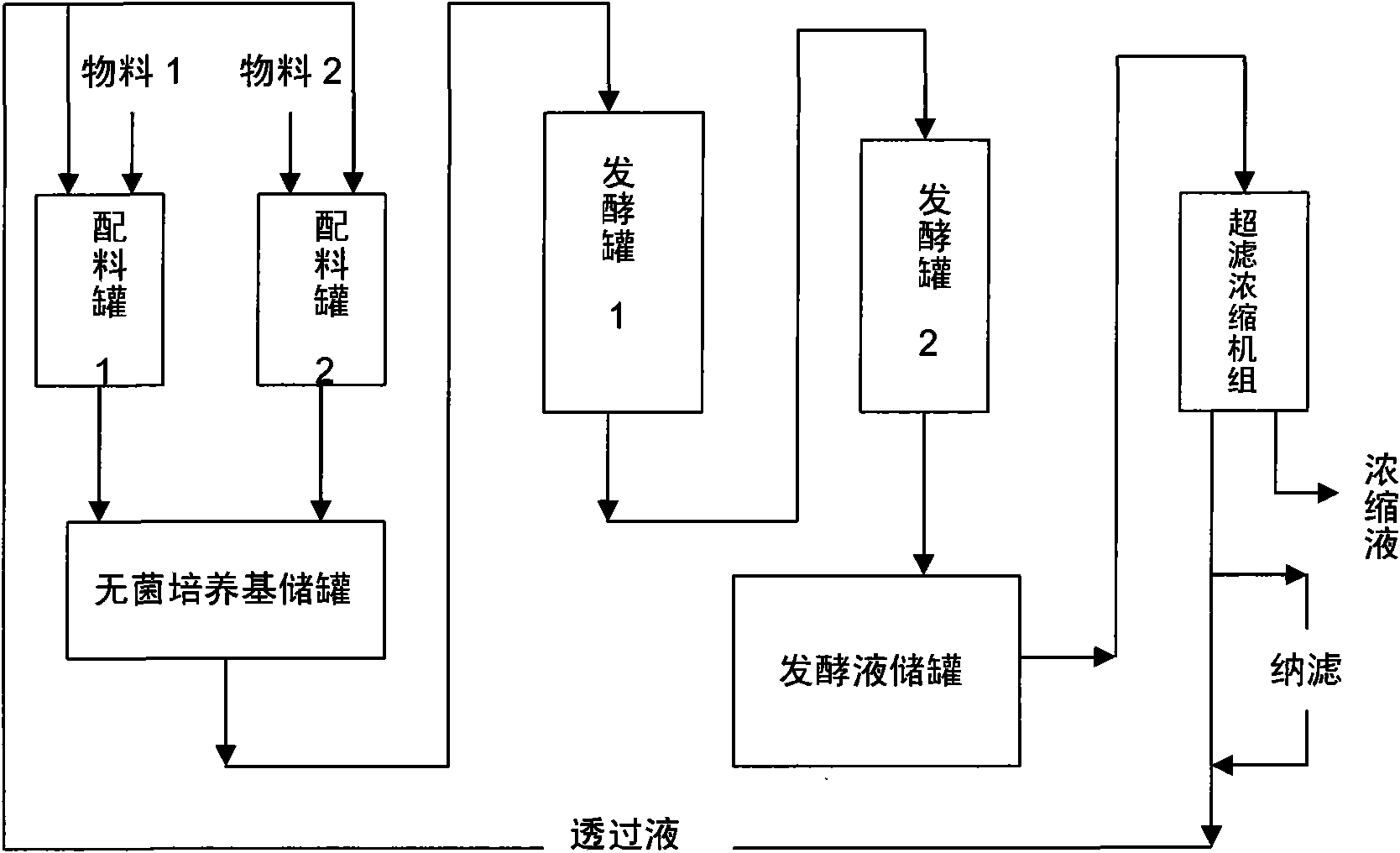

[0036] A straight-leaf turbine-type ventilated fermenter is adopted, and the fermentation method adopts a cascaded strain proliferation fermentation method. The feeding coefficient of fermenter 1 is 75%, and the inoculation amount is 8%. Two stages of fermenters are connected in series, fermenter 1 is cultivated for 13 hours, 90% of the culture medium is transferred to fermenter 2, and fresh medium is added to fermenter 1 to re-prolifer...

Embodiment 2

[0040]a) The quality composition (g / L) of the preparation fermentation medium of fermentation medium:

[0041] Starch sugar 15, (NH 4 ) 2 SO 4 3,K 2 HPO 4 4. MgSO 4 0.5, CaCl 2 1.0, corn syrup 0.9, water 1000.

[0042] Get 15% of the fermentation water for preparation (NH 4 ) 2 SO 4 Components, 85% of the fermentation water is used to prepare other components, which are respectively sterilized at 120°C for 8 minutes and then mixed in the fermenter for later use:

[0043] b) Fermentation method and fermentation condition control

[0044] Straight-leaf turbine-type ventilated fermenter is adopted, and the fermentation method adopts the in-situ strain multiplication fermentation method, and the feeding coefficient of fermenter 1 is 70%, and the inoculation amount is 5%. Two stages of fermentors are connected in series, fermentor 1 is cultivated for 10 hours, 85% of the culture medium is transferred to fermentor 2, and fresh medium is added to fermentor 1 to re-prol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com