Method for preparing polymer/houghite nano composite material

A technology of nanocomposite materials and hydrotalcite, which is applied in the field of preparation of polymer/hydrotalcite nanocomposite materials, can solve the problems of long process route and impact, and achieve the effects of interaction, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

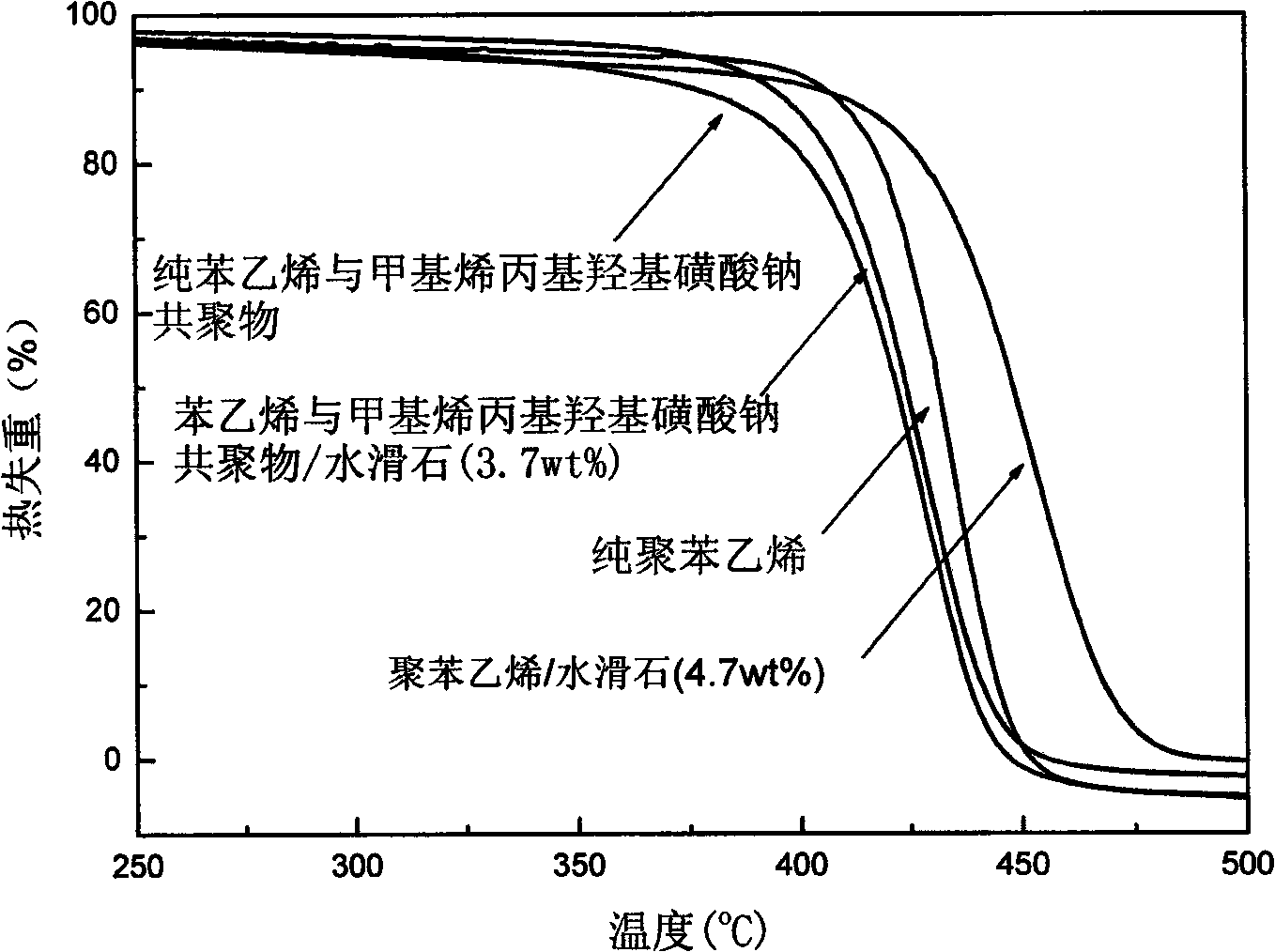

Image

Examples

Embodiment 1

[0028] 0.5 g of hydrotalcite ([Mg 2+0.67 m 3+ 0.33 (OH - ) 2 ] 0.33+ (CO 3 2- 0.165 )·0.33H 2 O, produced by Huzhou Linghu Xinwang Chemical Co., Ltd.) was added to 100 g of water, stirred at room temperature for 1 h, and then dispersed by ultrasonic waves (power 500 w) for 10 min to obtain a hydrotalcite suspension.

[0029] Add 30g of styrene, 2.0g of sodium lauryl sulfate, 0.2g of potassium persulfate and 100g of deionized water into the reactor, stir at room temperature for 10min, raise the temperature to 70°C to start polymerization, and the polymerization reaction time is 8 hours. After the end, lower the temperature to allow the emulsion to cool naturally to room temperature.

[0030] Add 100g of hydrotalcite suspension to 50g of polymer emulsion by dropwise addition. The dropwise addition time is 1h. After the dropwise addition is completed, stir at 50°C for 1 hour. The composite particle suspension is filtered, washed, and dried to obtain the hydrotalcite cont...

Embodiment 2

[0032] The preparation of hydrotalcite suspension and polymer emulsion is the same as in Example 1.

[0033] Add 100g of hydrotalcite suspension to 100g of emulsion at one time, then raise the temperature to 40°C and stir for 3 hours. The composite particle suspension is filtered, washed and dried to obtain a polystyrene / hydrotalcite nanometer with a hydrotalcite content of 2.4wt%. composite material.

Embodiment 3

[0035] The preparation of hydrotalcite suspension and emulsion is the same as in Example 1.

[0036] Add 50g of hydrotalcite suspension to 100g of emulsion by dropwise addition, the dropwise addition time is 30min, after completion of the dropwise addition, heat up to 70°C and stir for 3 hours, the composite particle suspension is filtered, washed and dried to obtain hydrotalcite The content is 1.2wt% polystyrene / hydrotalcite nanocomposite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com