Processing method for electrochemically modifying carbon nano tube

A technology of carbon nanotubes and treatment methods, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of reducing the catalytic activity of carbon nanotubes, achieve good electron transfer rate, good hydrophilicity, improve The effect of charge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

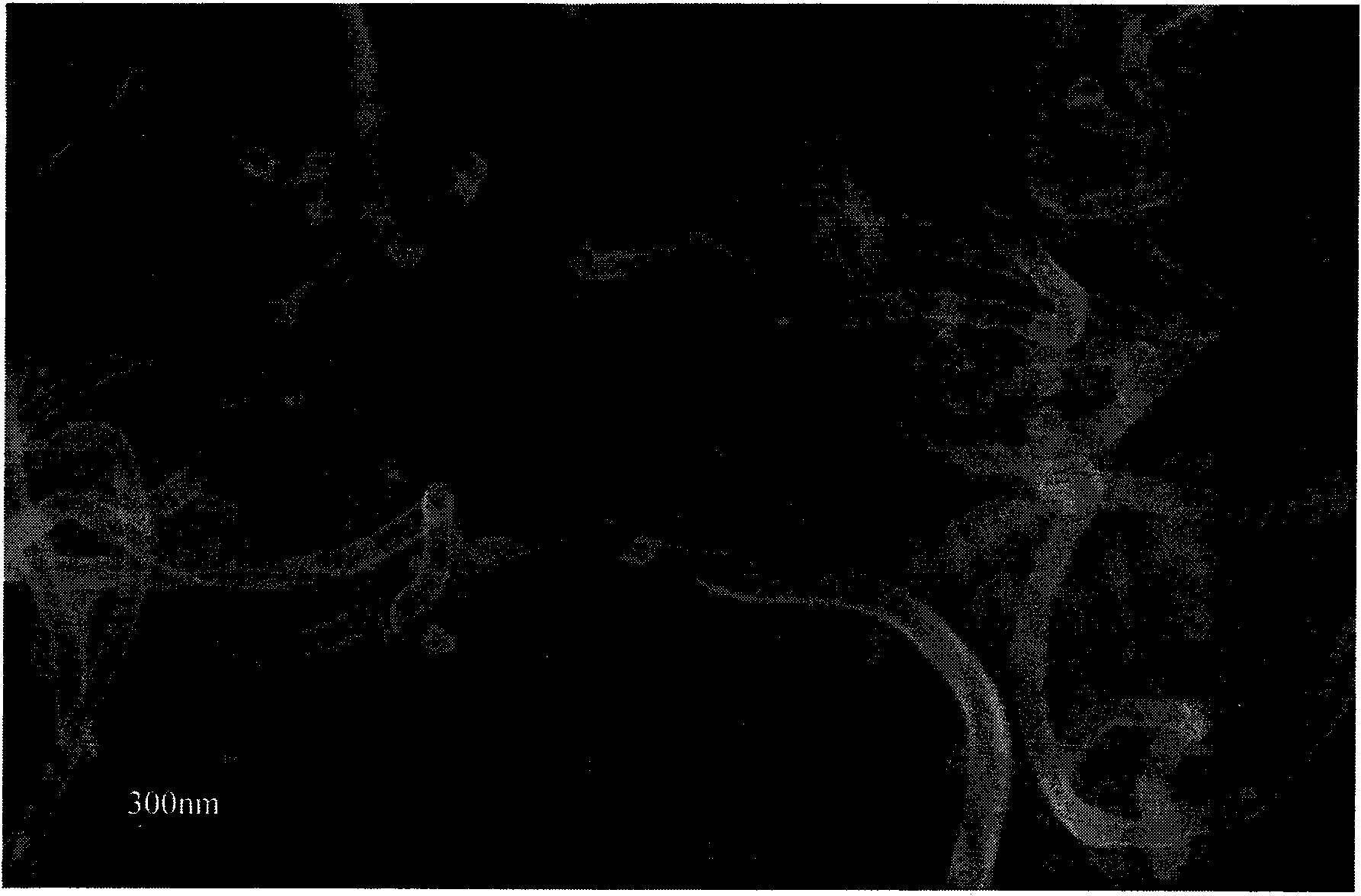

[0033] Using metal as the substrate, first spraying iron on the substrate as a catalyst, and then growing carbon nanotubes on the substrate by chemical vapor deposition, figure 1 It is a scanning electron microscope picture of carbon nanotubes grown on a metal substrate, and the diameter of carbon nanotubes is about 80nm. The metal substrate grown with carbon nanotubes is cut into small metal sheets to prepare electrodes. In a 1mol / L potassium hydroxide solution in an electroplating tank, carbon nanotubes were used as the working electrode, and a constant voltage of 0.8V was applied to the working electrode for 5 minutes through a CHI660A electrochemical workstation. figure 2 It is the scanning electron microscope picture after treatment modification. from figure 2 It can be seen that the carbon nanotubes are cut into many small segments, and the defects of the walls and ends of the carbon nanotubes are significantly increased, resulting in a significant increase in the sp...

Embodiment 2

[0035] Preparation of carbon nanotube electrodes As described in Example 1, the metal substrate grown with carbon nanotubes was cut into small metal sheets to prepare electrodes. In a 1mol / L potassium hydroxide solution, carbon nanotubes were used as the working electrode, and a constant voltage of 5 V was applied to the working electrode for 3 minutes through a CHI660A electrochemical workstation. image 3 It is the scanning electron microscope picture after treatment modification. from image 3 It can be seen from the figure that after being treated by this method, the original carbon nanotubes are cut into many small segments, and the defects of the tube walls and ends of the carbon nanotubes are significantly increased, resulting in a significant increase in the specific surface area and an increase in catalytic efficiency.

Embodiment 3

[0037] Preparation of carbon nanotube electrodes As described in Example 1, the metal substrate grown with carbon nanotubes was cut into small metal sheets to prepare electrodes. In a 1mol / L potassium hydroxide solution, carbon nanotubes were used as the working electrode, and a constant voltage of 1V was applied to the working electrode for 4 minutes through a CHI660A electrochemical workstation. Figure 4 It is the test picture of the water drop contact angle on the surface of untreated carbon nanotubes, and the contact angle of the water drop in the figure is 141°. It can be seen from the figure that water droplets do not spread on the surface of carbon nanotubes at all, and the surface of carbon nanotubes is superhydrophobic. Figure 5 It is the test picture of the water drop contact angle on the surface of the treated carbon nanotube, and the contact angle of the water drop in the figure is 53°. It can be seen from the figure that water droplets can spread on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com