Smoke exhaust pipe penetration method

A technology for exhaust pipes and cabins, which is applied in the field of smoke exhaust pipes and cabins, which can solve problems such as unsatisfactory and unsuitable for use, and achieve the effect of simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

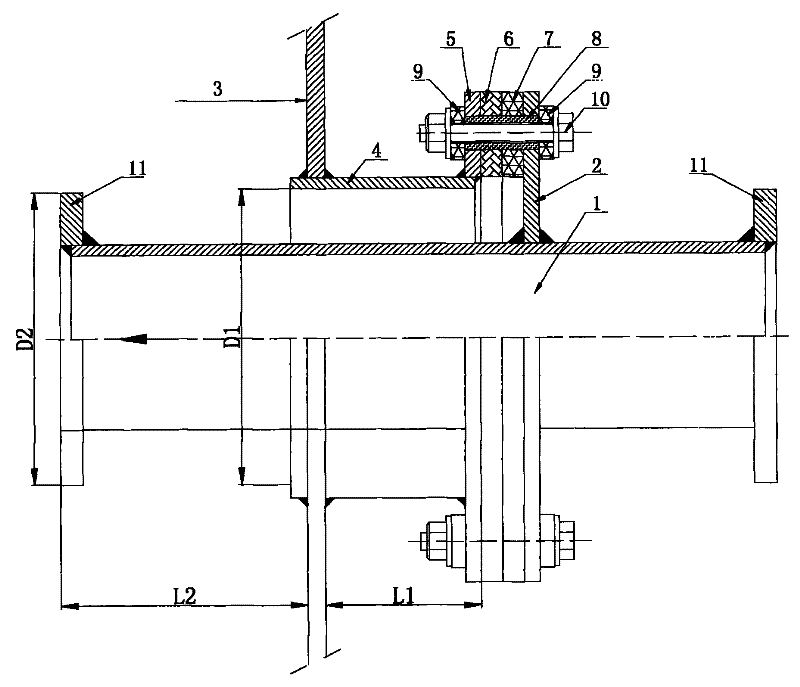

[0014] The present invention is described in further detail below in conjunction with accompanying drawing:

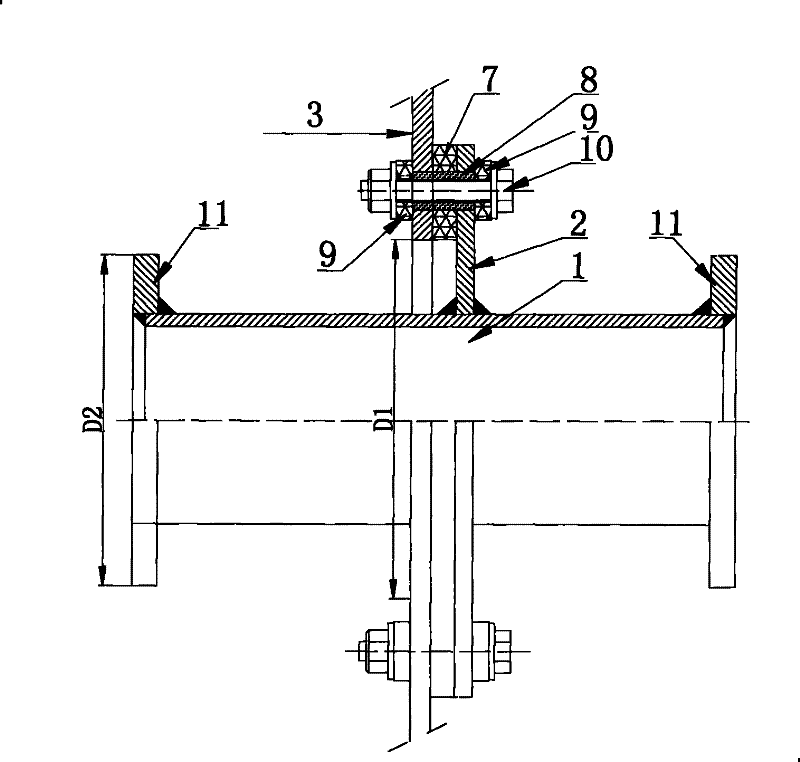

[0015] Such as figure 2 As shown, in the smoke exhaust pipe opening method of the present invention, the components used include the opening steel pipe 1, double plate 2, cylindrical coaming 4, seat plate 5, gasket 6, heat insulation pad 7, bolt heat insulation sleeve 8. Bolt heat insulation pad 9, bolt 10 and flanges 11 at both ends of the steel pipe through the cabin. The open cabin steel pipe 1 is a short pipe that needs to pass through the bulkhead 3 in the smoke exhaust pipeline; the double plate 2 is an annular steel plate welded on the open cabin steel pipe 1; the cylindrical coaming 4 is welded around the opening of the bulkhead 3 The reinforcement plate can be a steel pipe or rolled with a steel plate; the seat plate 5 is an annular plate welded on the end of the cylindrical coaming plate 4, which can be cut with a steel plate or a standard flange can be sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com