Parallelism adjusting method of welding head and sample applicable to ultrasonic nano welding

An adjustment method and parallelism technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult to ensure complete parallelism, affecting the welding effect of nano-materials, and ineffective transmission of ultrasonic energy, so as to solve the problem of contact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment is implemented under the following conditions of implementation and technical requirements:

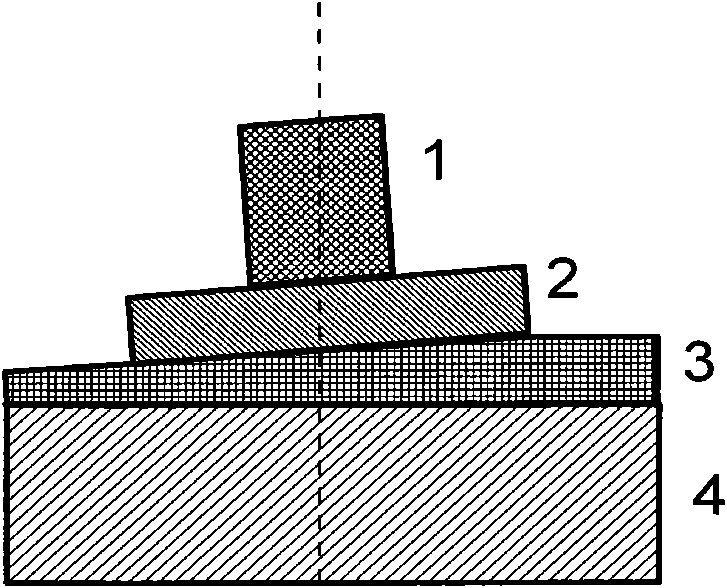

[0024] The area of the welding head is 1cm 2 The aluminum oxide superhard flat welding head, the material to be welded is single-walled carbon nanotubes. Use the method of dielectrophoretic deposition to arrange the single-walled carbon nanotubes between the titanium microelectrodes with a spacing of 1.5 microns; the elastic rubber pad 3 is made of silicone rubber material, and the silicone rubber is made of polydimethylsiloxane (PDMS) spin Coated on a 3-inch glass substrate, the spin-coating speed is 1500 rpm, and the thickness of the spin-coating on the glass is 50 microns. The sample 2 to be welded is placed on the rubber pad 3, and the rubber pad 3 is placed on the pitch table 4 that has been preliminarily leveled. After applying a static pressure of 0.4 MPa to the welding head, the sample 2 was welded with the welding parameters of ultrasonic welding fr...

Embodiment 2

[0027] This embodiment is implemented under the following conditions of implementation and technical requirements:

[0028] The area of the welding head is 1cm 2 The aluminum oxide superhard flat welding head, the material to be welded is multi-walled carbon nanotubes. Electrophoretic deposition method is used to deposit multi-walled carbon nanotubes on the titanium metal electrode surface. The elastic rubber pad 3 adopts silicon rubber material. The preparation of the silicone rubber pad is to spin-coat polydimethylsiloxane (PDMS) on a 3-inch silicon lining. On the bottom, the rotation speed was 500 rpm during spin coating, and the thickness of spin coating on the glass was 500 μm. The sample 2 to be welded is placed on the rubber pad 3, and the rubber pad 3 is placed on the pitch table 4 that has been preliminarily leveled. After applying a static pressure of 0.2 MPa to the welding head, the sample 2 was welded with the welding parameters of ultrasonic welding frequency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com